Glove

a glove and glove technology, applied in the field of gloves, can solve the problems of inability to stand any longer-lasting heat and flame radiation, substantial risk of user hand being exposed to suffering burns, and inability to absorb hot water vapors, etc., and achieve the effect of reliable and space-saving glove fit on the arm of the user, good fit, and reliable protection from external influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

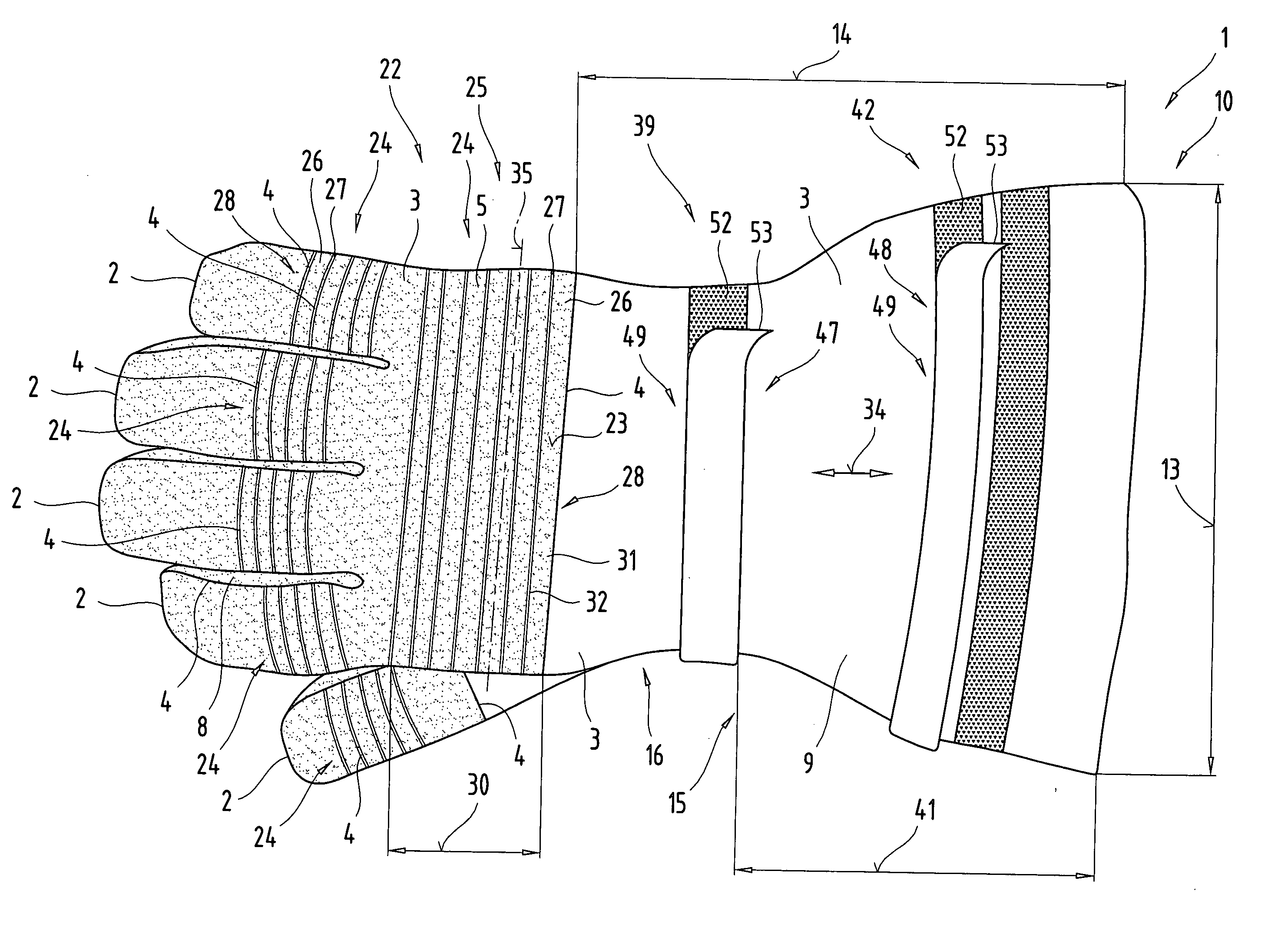

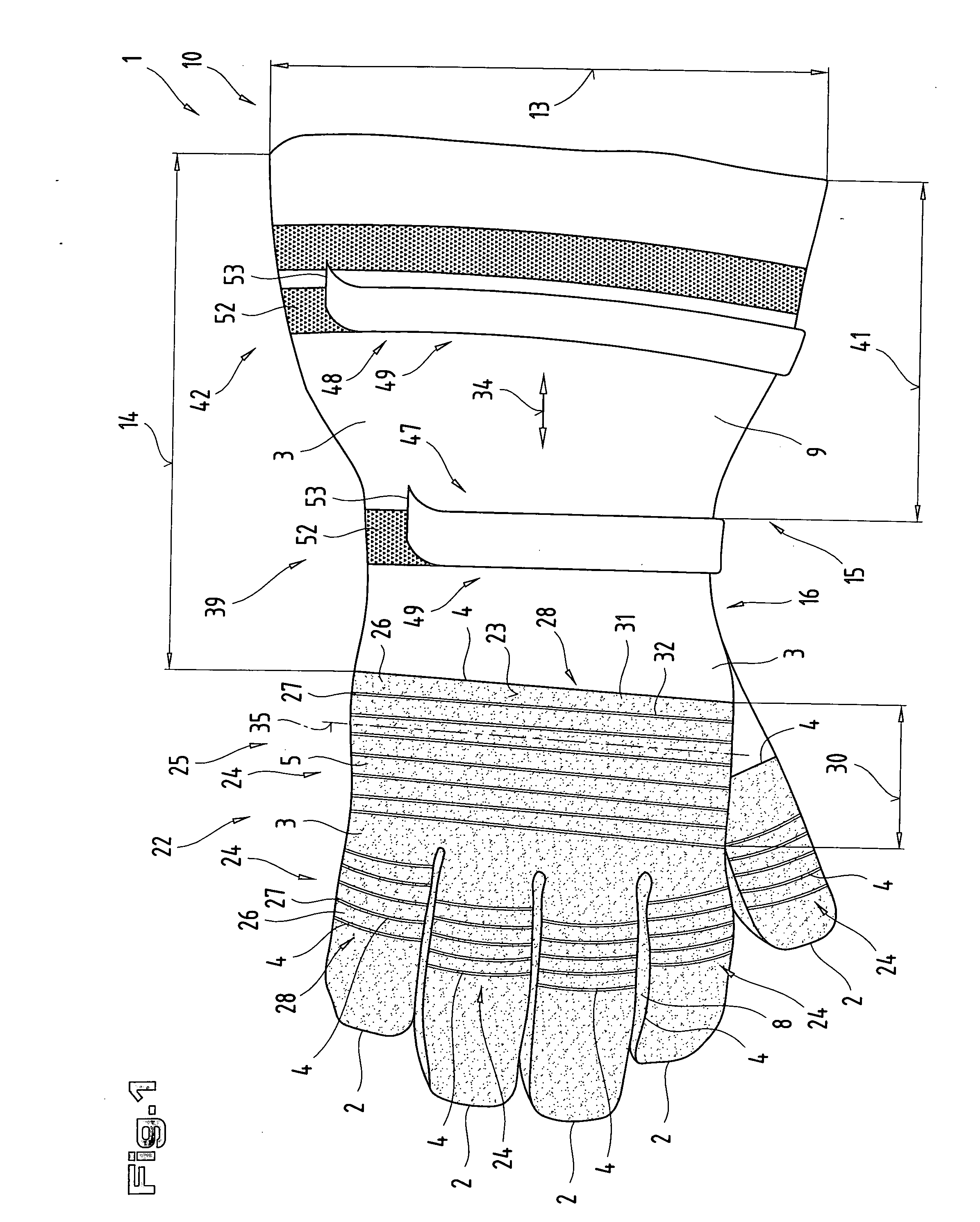

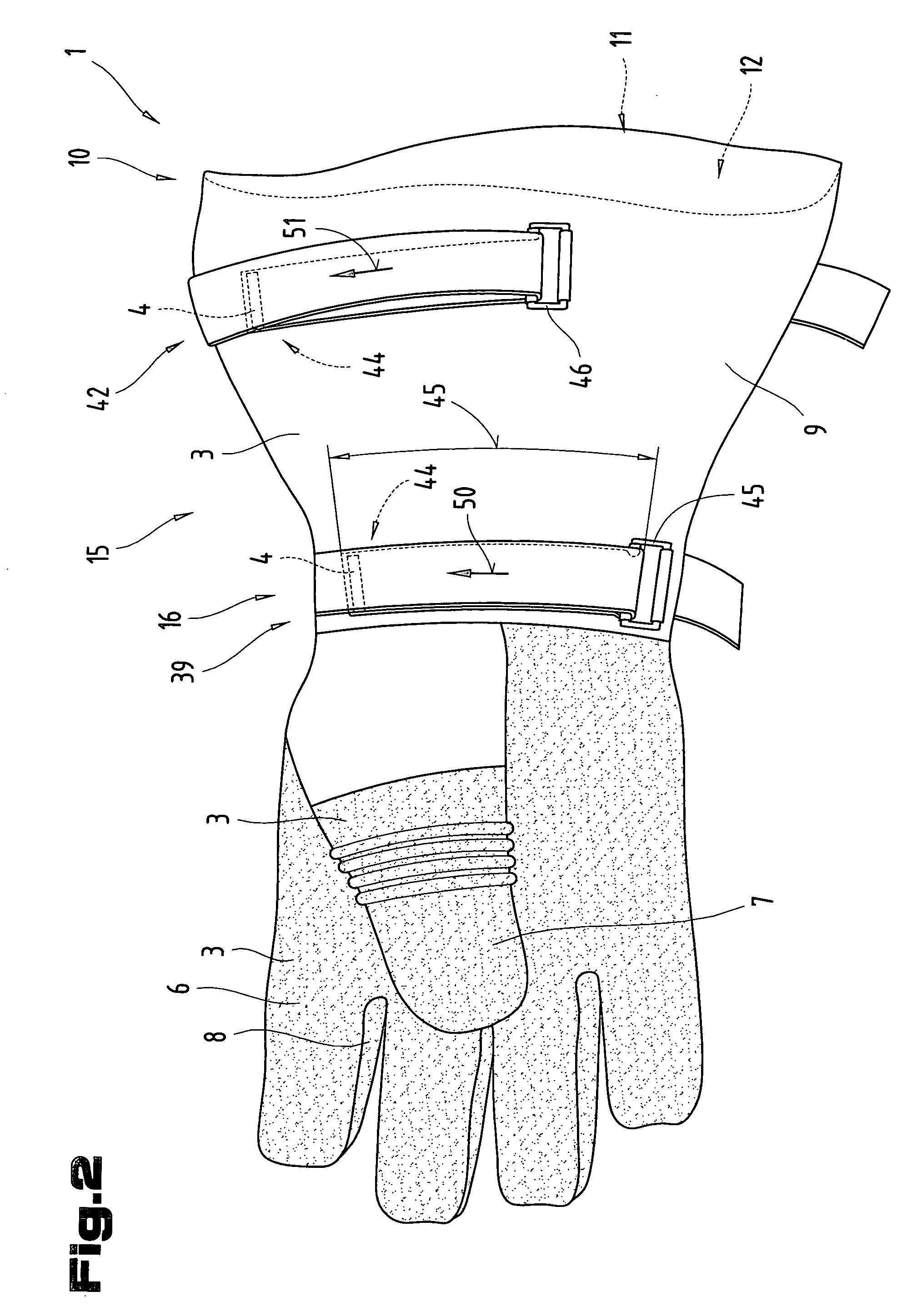

[0043] It is noted here by way of introduction that in the different embodiments described herein, identical components are provided with identical reference numbers and identical component designations, whereby the disclosures contained throughout the present specification can be applied in the same sense to identical parts with identical reference numbers and component designations. Furthermore, positional data selected in the specification such as, e.g. “top”, “bottom”, “lateral” etc., relate to the directly described and shown figure, and have to be applied in the same sense to any new position where as position has changed. Moreover, individual features and combinations of features in the different exemplified embodiments shown and described herein may per se represent independent inventive solutions, or solutions as defined by the invention.

[0044] FIGS. 1 to 3 show a first exemplified embodiment of a glove 1, on which several solutions of the problem as defined by the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com