Breathable workshoes and methods for manufacturing such

a technology for workshoes and breathable materials, applied in the field of workshoes, can solve the problems of not being able to meet the needs of various work environments, flip-flops are typically not compatible with the work environment, sandals are not waterproof, etc., and achieve the effect of increasing the functionality of the shoe and increasing the comfort and/or functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Among other things, the present invention provides various footwear pieces, and methods for manufacturing such pieces. In various cases, the footwear pieces are molded from a lofted, or foam material material. Further, in various cases, the footwear pieces include liquid conductors formed around ventilators, or holes, in the footwear piece. Such liquid conductors operate to disperse liquids away from a foot inserted in the footwear piece.

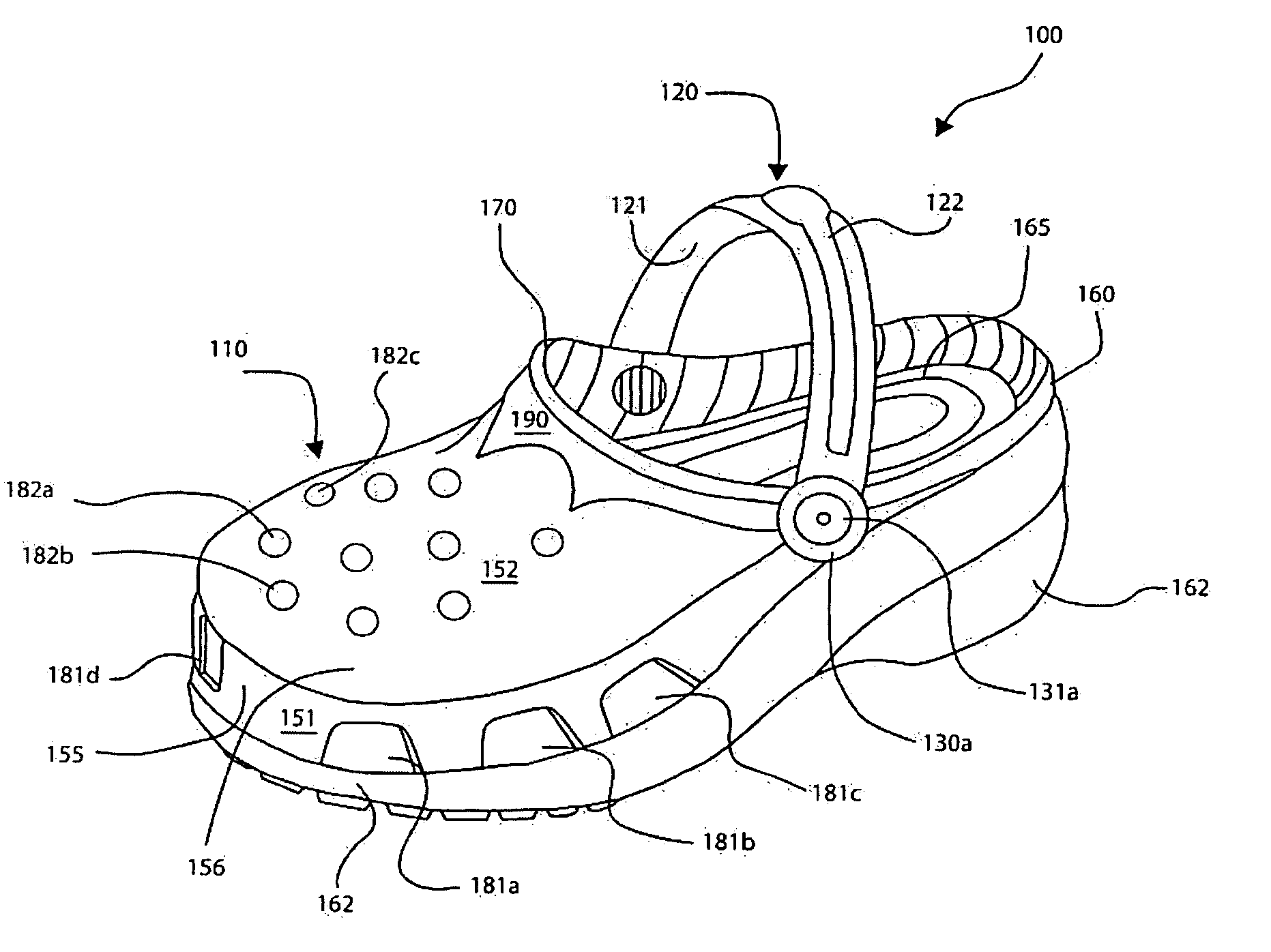

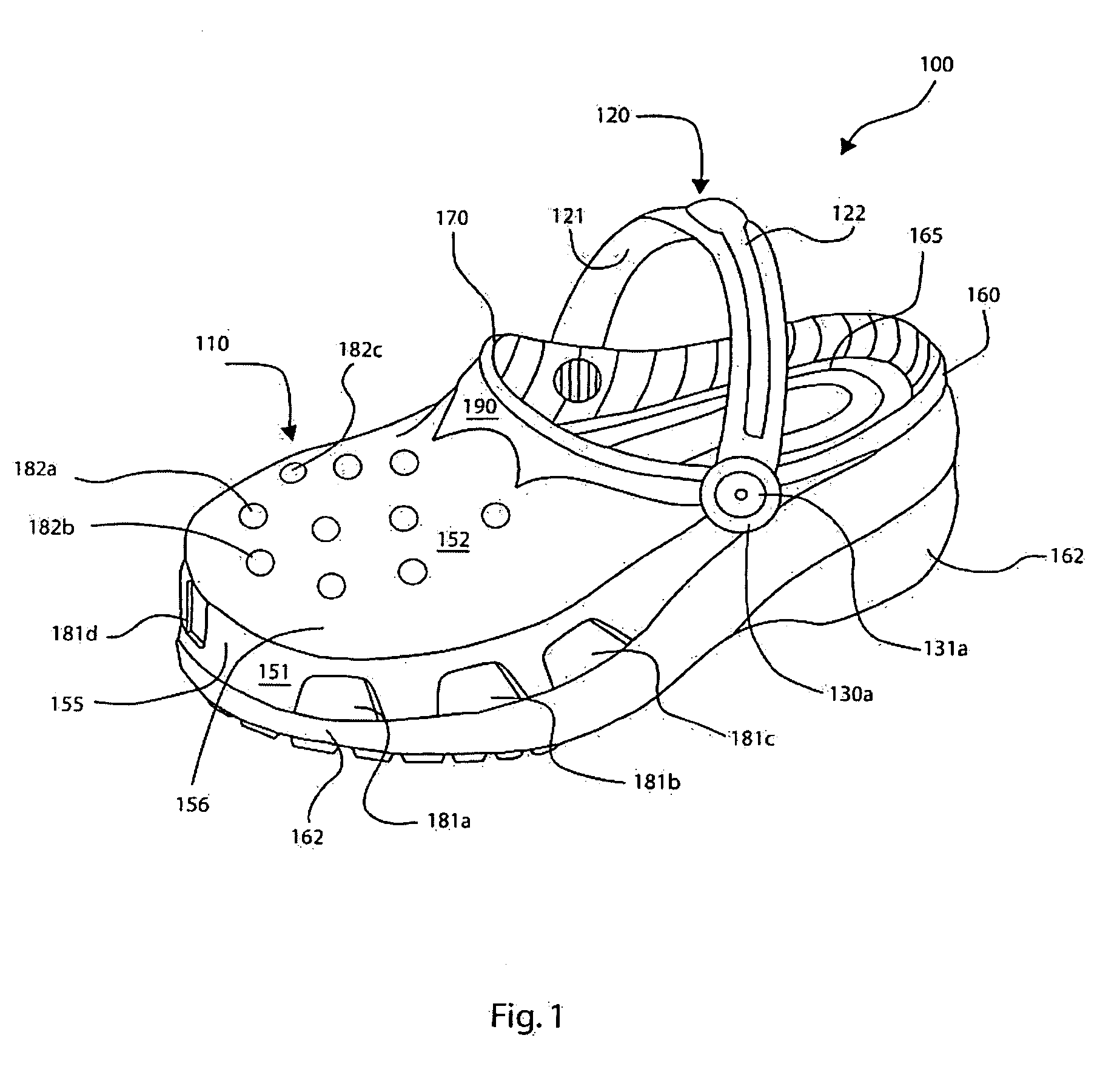

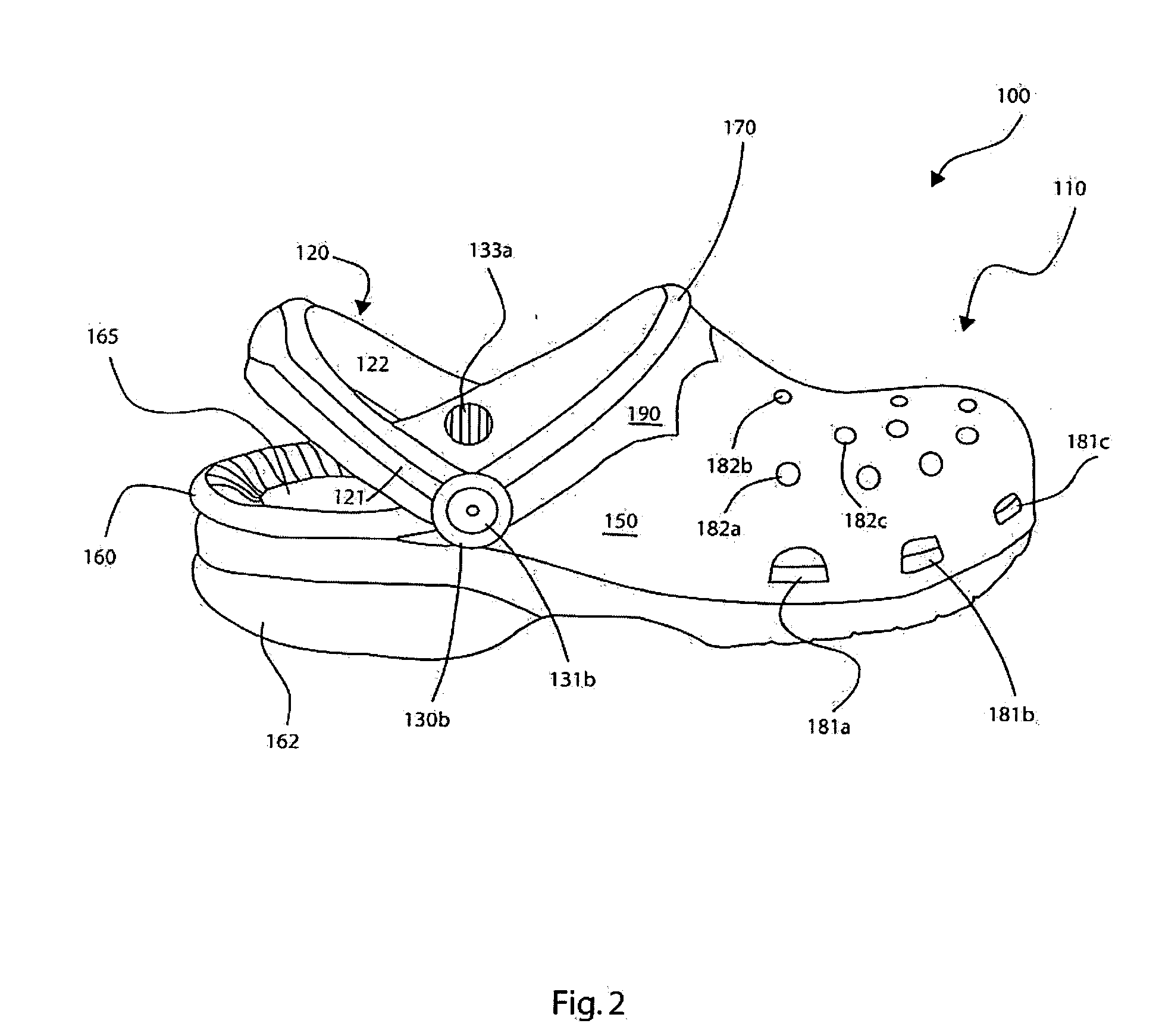

[0026] Turning to FIG. 1, a footwear piece 100 in accordance with some embodiments of the present invention is illustrated. Footwear piece 100 includes a base section 110 and a strap section 120. Base section 110 includes an upper 150 and a sole 162. In some embodiments, base section 110 is molded as a single piece of foam material. In other embodiments, sole 162 is molded from a foam or other foam like material, while upper 150 is manufactured of a different material that is later assembled with sole 162 to form base section 110.

[0027] Upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| moldable | aaaaa | aaaaa |

| frictional forces | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com