Garden hose reel

a technology for hose reels and hoses, applied in fire rescue, transportation and packaging, thin material handling, etc., can solve the problems of reducing the service life of hose carts, reducing the service life of hoses, and consuming significant space, so as to facilitate the winding of hoses and facilitate stacking. , the effect of preventing tangling of hoses during winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

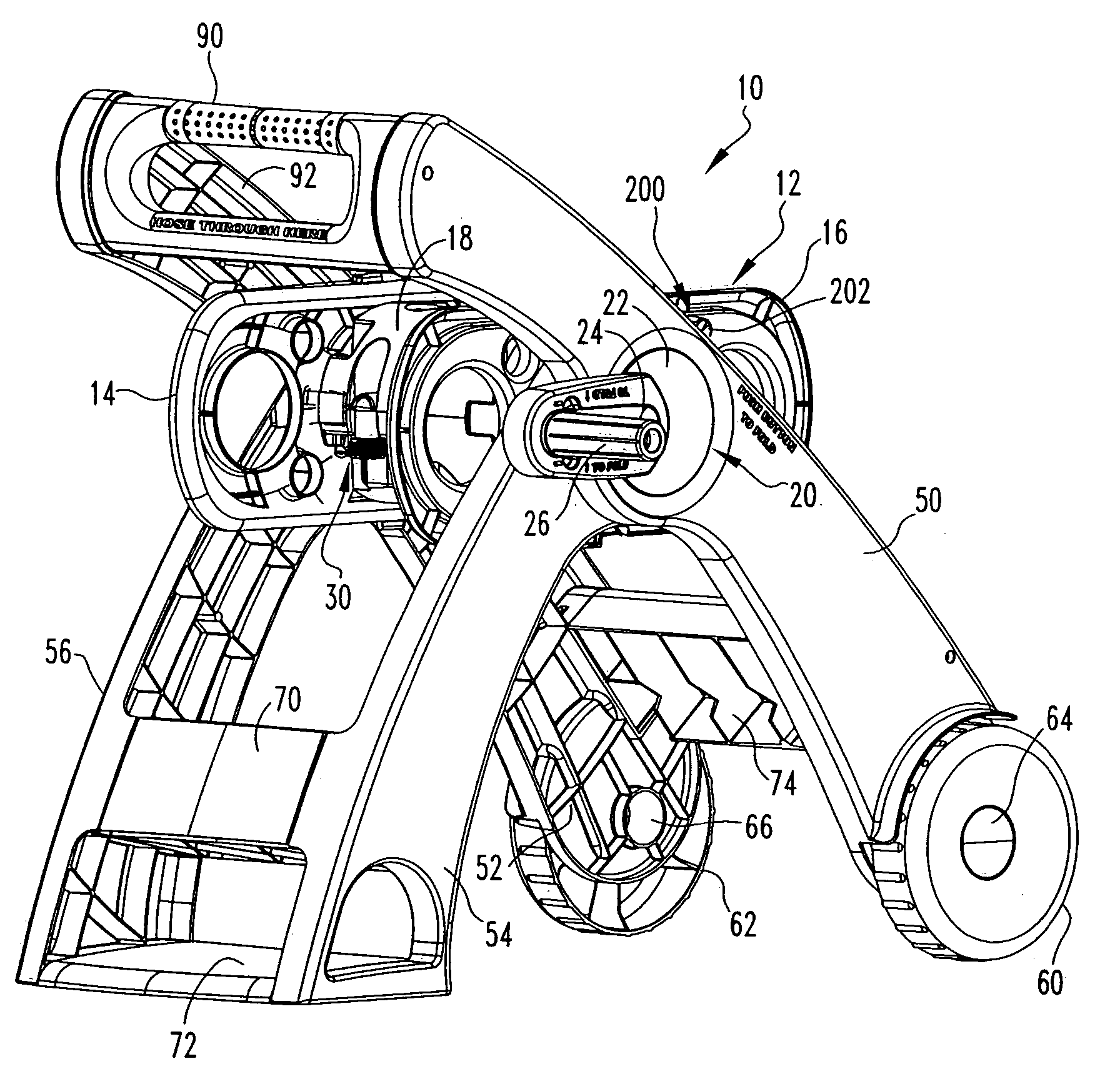

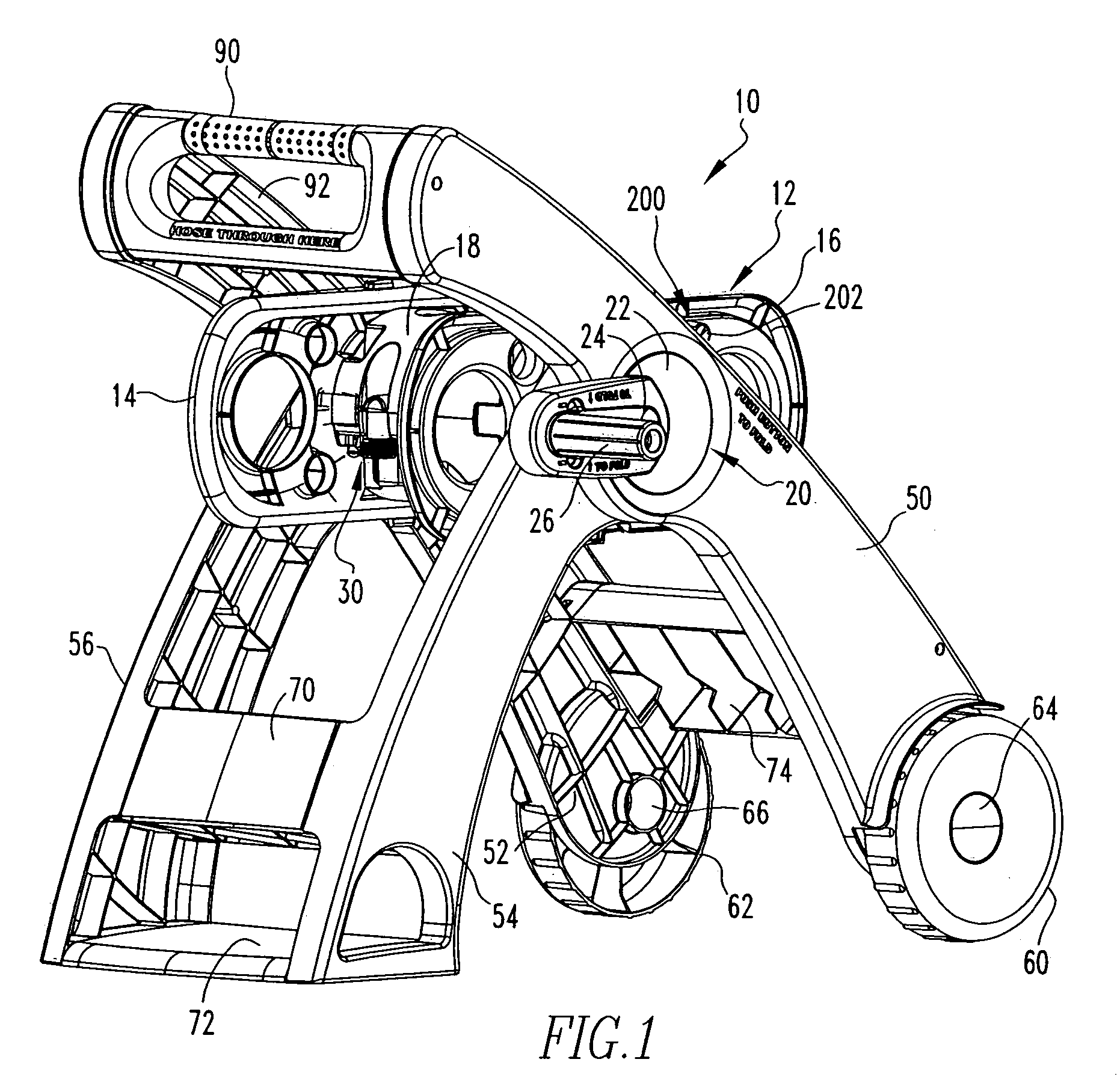

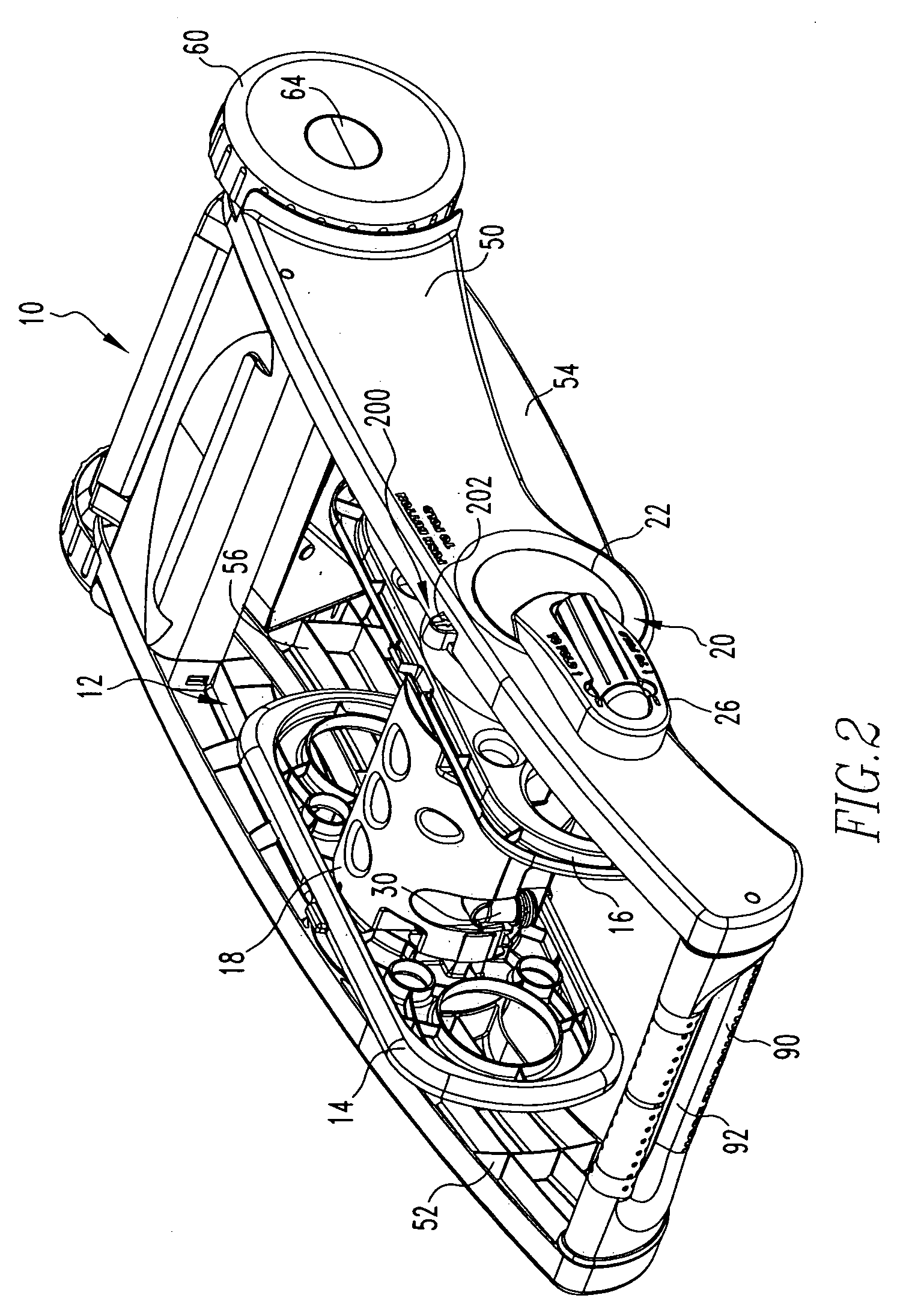

[0036]FIG. 1 shows the improved hose reel 10 in a first, open, ready to use position (minus the garden hose). The hose reel 10 includes a basket assembly 12 for holding the garden hose (not shown). The basket assembly 12 includes opposed oblong flange members 14, 16 which allow for a “low profile” when the hose reel 10 is closed (see FIG. 2). The basket assembly 12 includes a hub 18 for winding thereon the garden hose. A crank assembly 20 is provided including a crank body 22 having a crank slot 24 and a pivotable crank handle 26. It will be appreciated that the crank handle 26 can be pivoted into the crank slot 24 (see FIG. 2) in order to further minimize the profile of the hose reel 10 when it is being shipped or moved about. A unique water supply 30 (FIG. 16) is also provided. The water supply will be described more fully below. A unique locking mechanism 200 (FIG. 14) is also provided. The unique locking mechanism will also be described below.

[0037] The main frame of the hose r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com