Portable hemming apparatus and method

a hemming device and portable technology, applied in metal working devices, metal-working apparatuses, manufacturing tools, etc., can solve the problems of large hemming devices, difficult to move, and fail to solve, and achieve the effect of compact siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

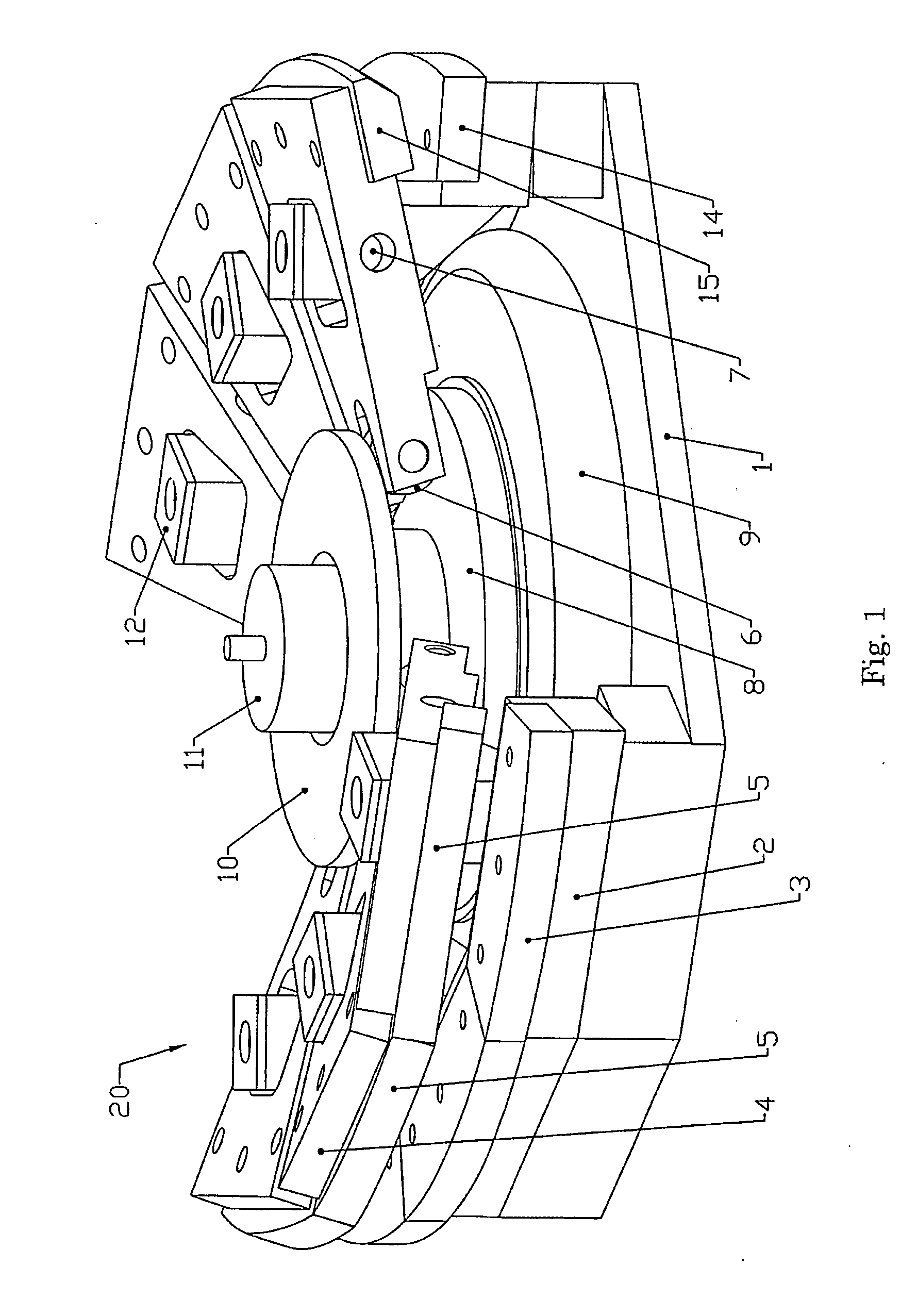

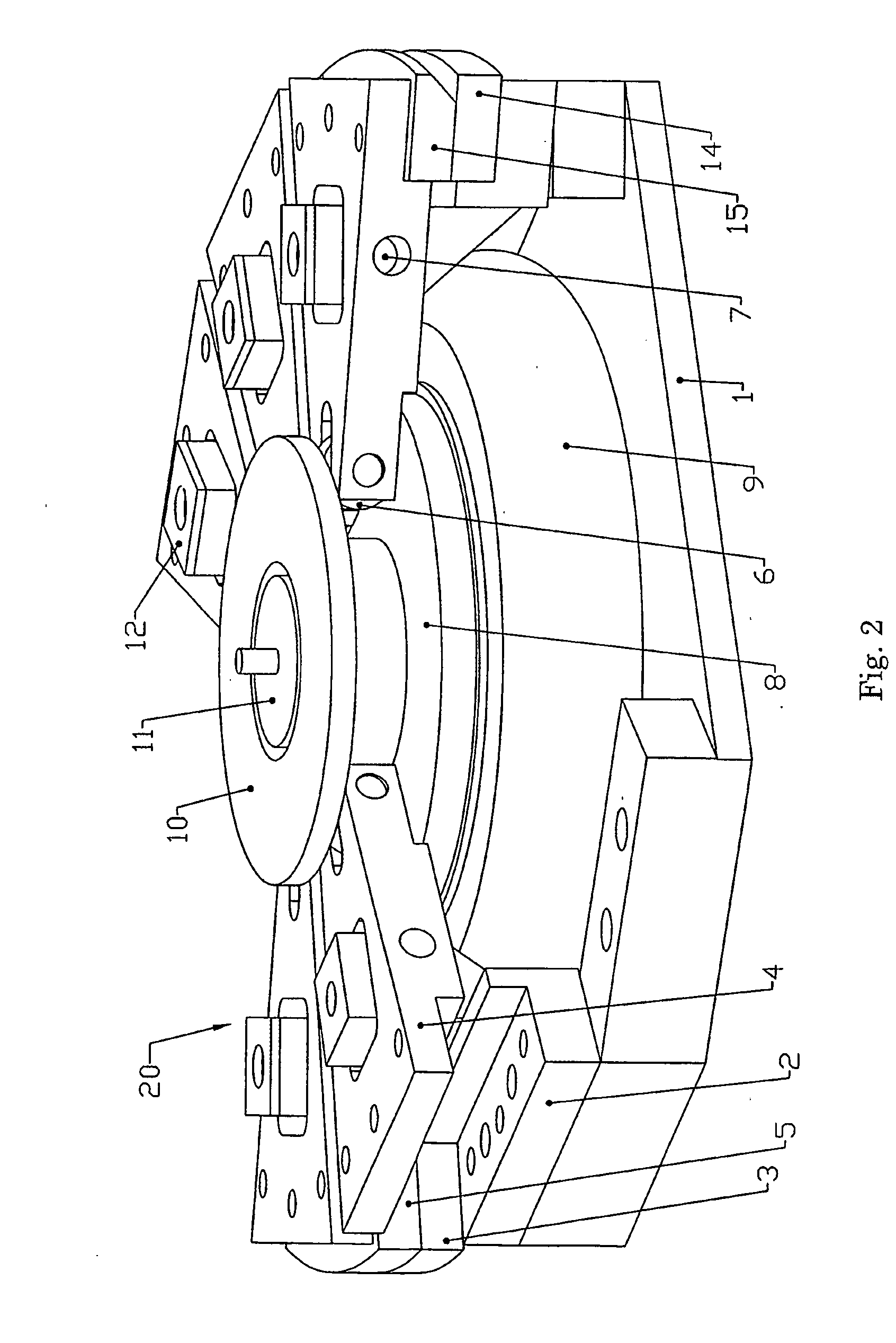

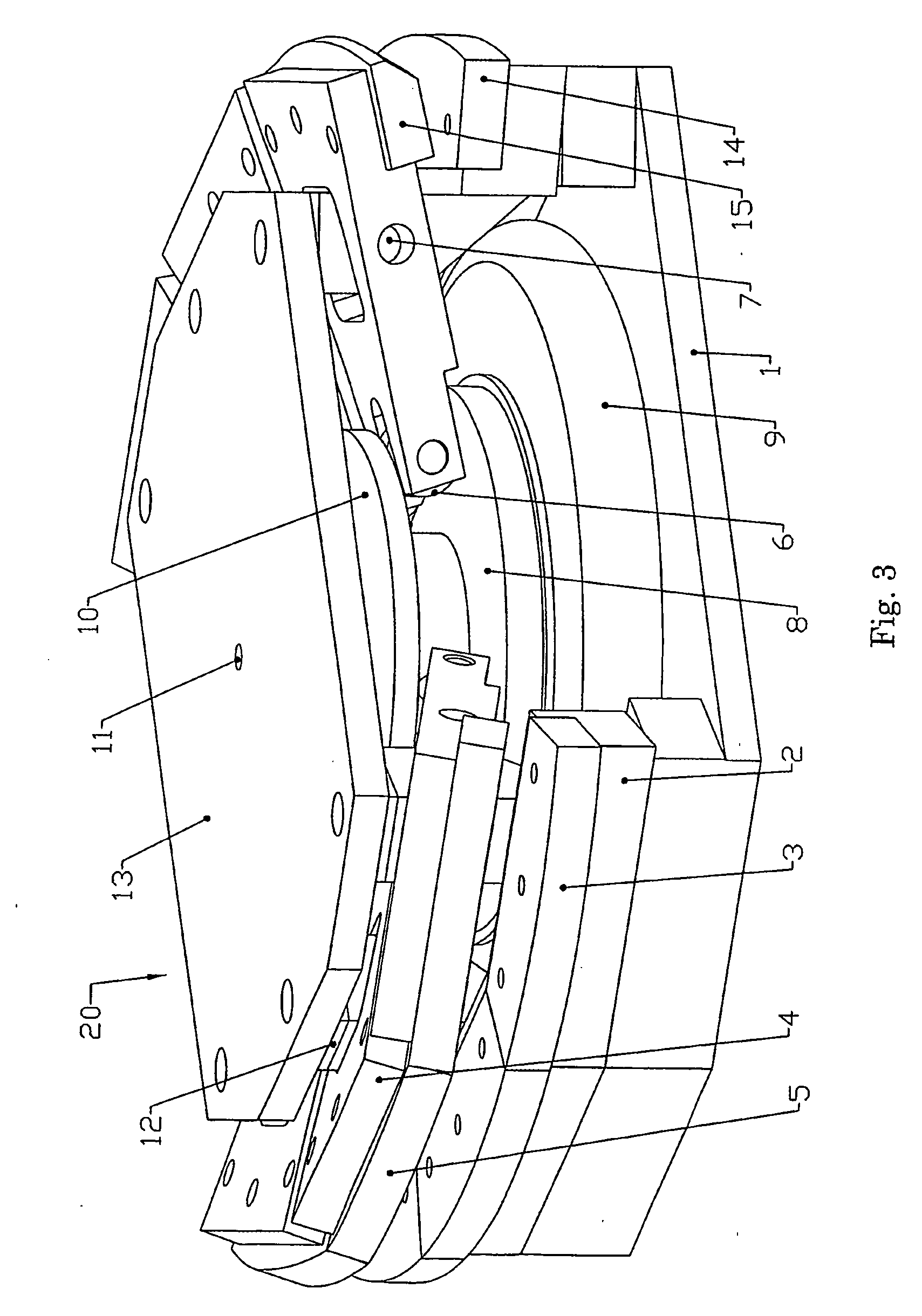

[0026] Referring now to the drawings in detail, numeral 20 generally indicates a portable hemming apparatus comprising a support structure 1, a plurality of modular hem die holders 2 attached to the support structure 1, and a corresponding plurality of hem punches 5, 15. A corresponding plurality of hem dies 3, 14 is mounted to the hem die holders 2. The hem punches 5, 15 are operatively connected to lever arms 4 which can freely rotate about pivots 7 mounted in the hem die holders 2. Moveable engagement members 6 fixed in the lever arms 4 rest on a roller plate 8, such roller plate 8 being attached to a first air spring drive 9. The first air spring drive 9 is connected to the support structure 1 on the side opposite the roller plate 8.

[0027]FIGS. 1 and 3 show the hemming apparatus 20 in a retracted position while FIG. 2 shows the hemming apparatus 20 in an extended hemming position. The hemming apparatus 20 is at rest in the retracted position. When fluid power is applied to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com