Combinational gardening rack

a gardening rack and comb technology, applied in the direction of dismountable cabinets, other domestic objects, mechanical equipment, etc., can solve the problems of inability to adjust the distance after assembly, and the design of fixed height frame boards cannot meet the different height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

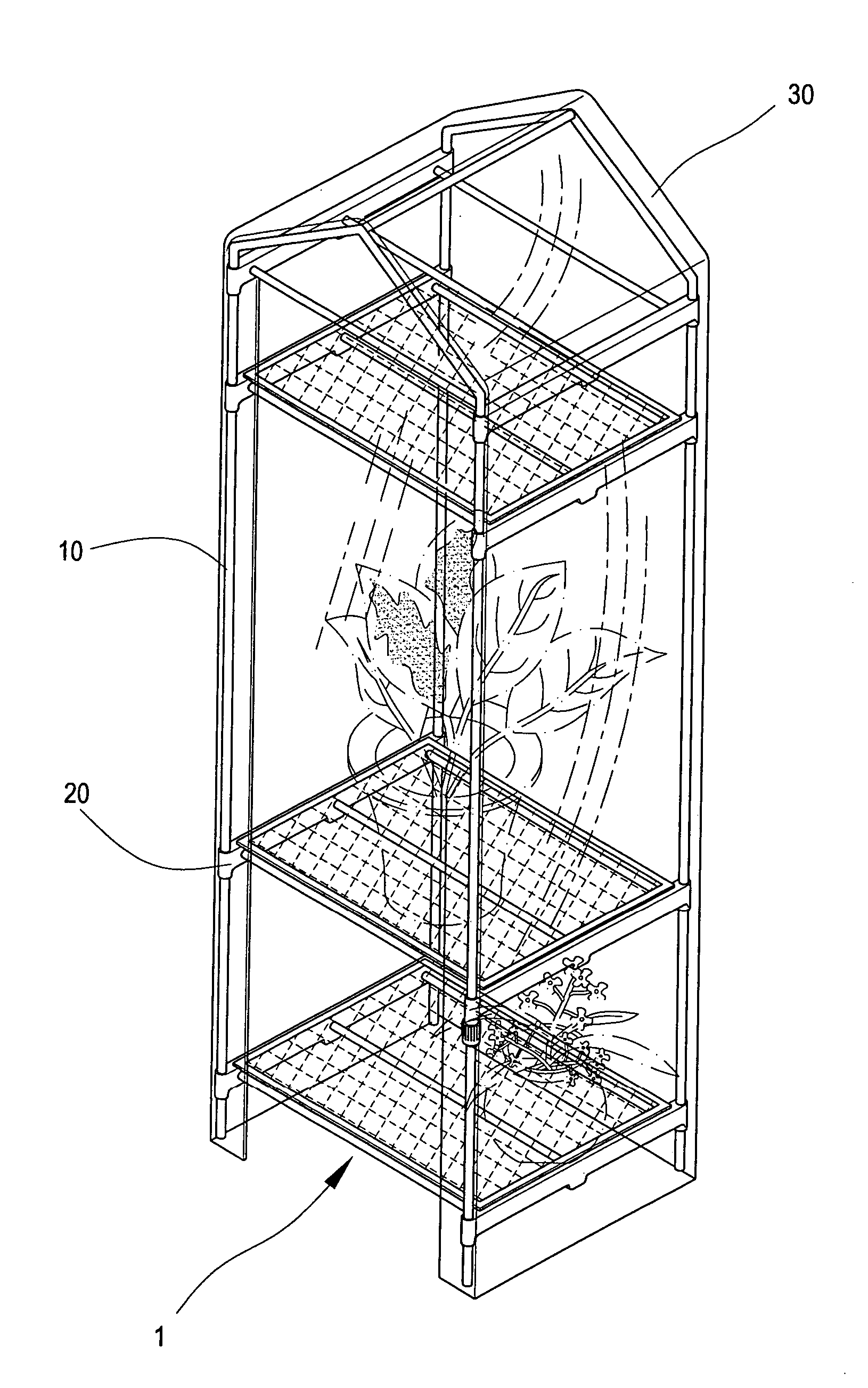

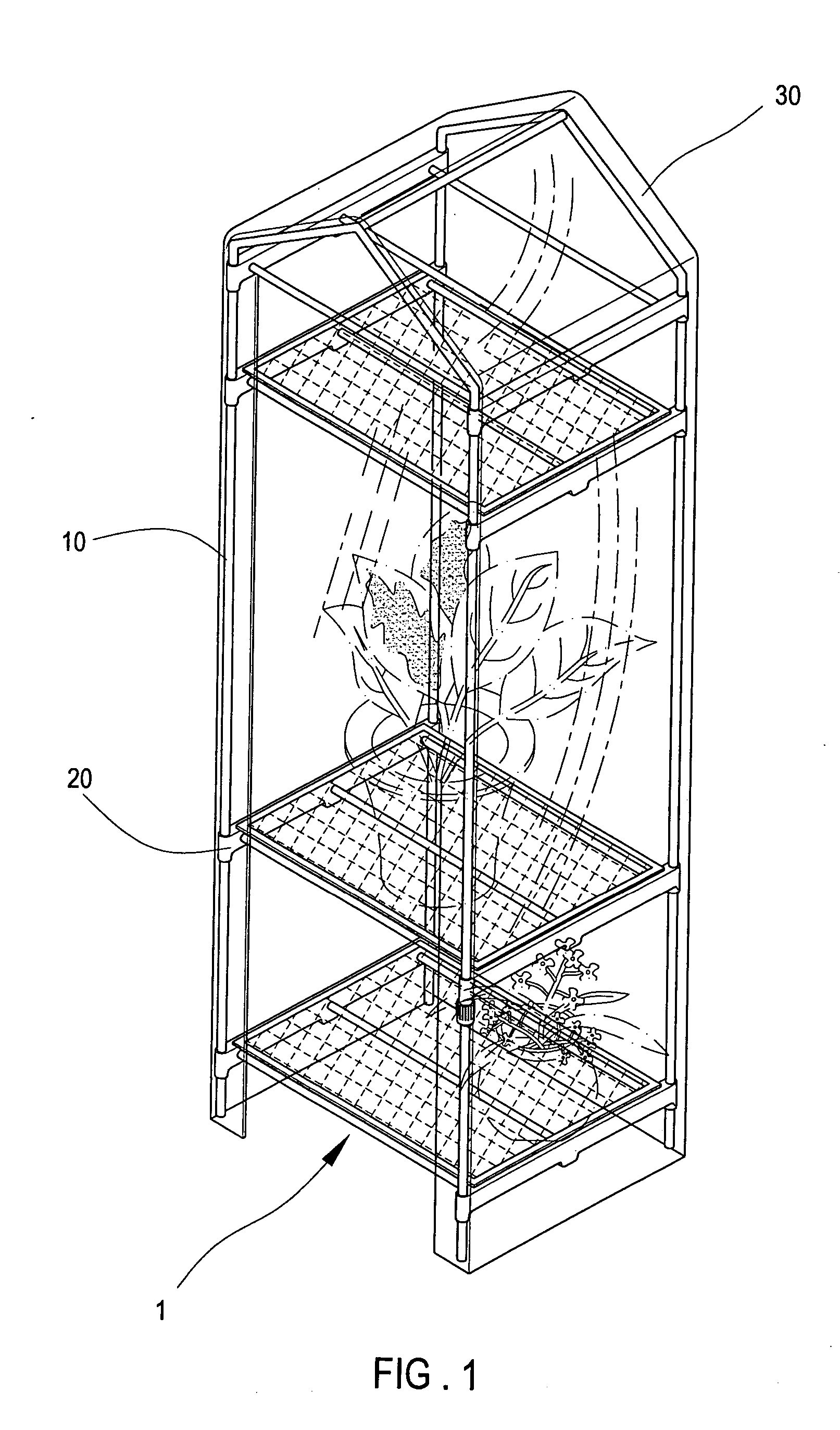

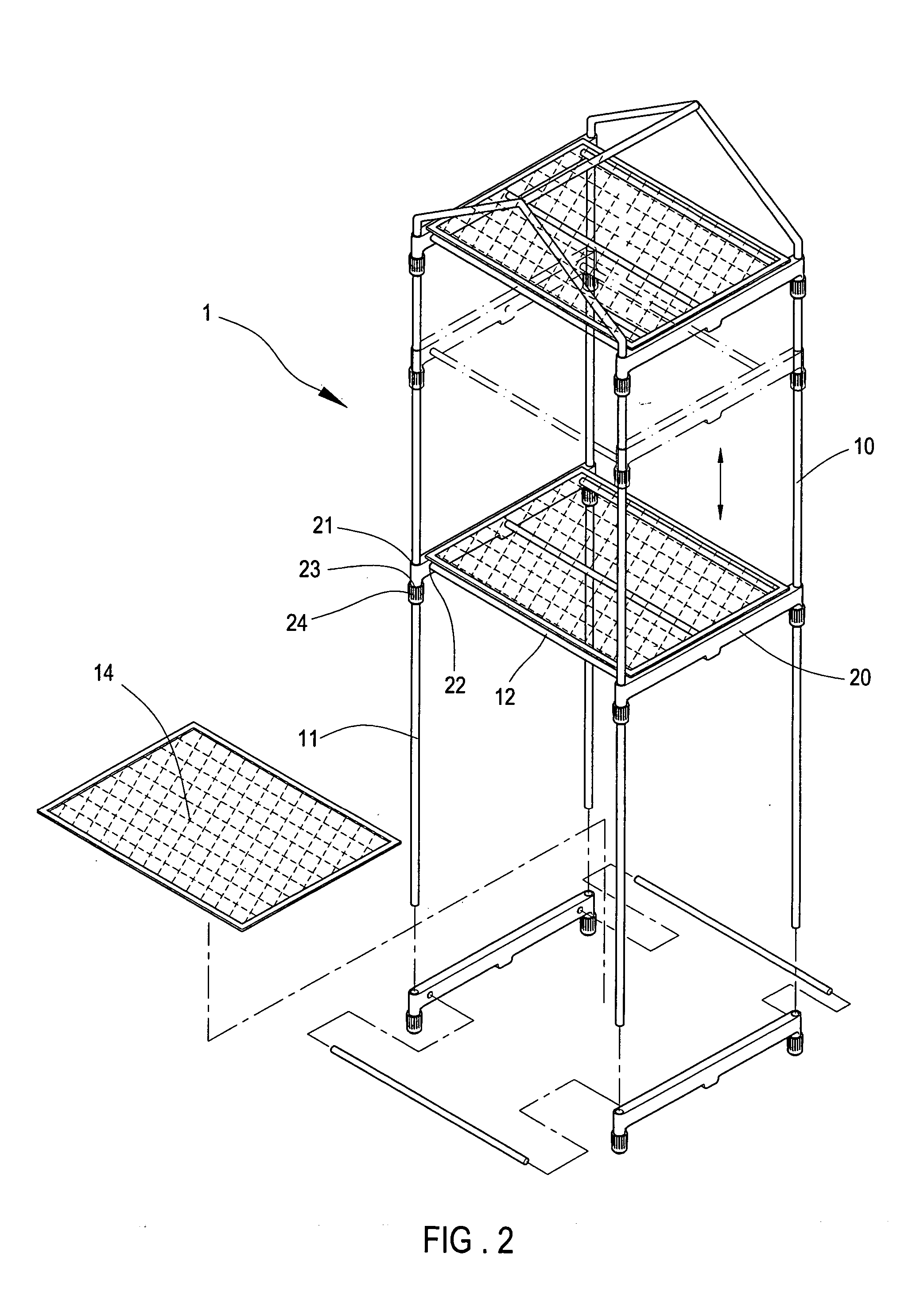

[0018] Referring to FIG. 1, FIG. 2 and FIG. 3, the present invention comprises several frames 10, several combining connectors 20 and a hood 30. The major feature of the present invention is that the combining connectors 20 have vertical and horizontal connecting holes 21, 22 with same diameter, the vertical connecting hole 21 is hollow in center, a wedge 23 stretches out from the bottom of the vertical connecting hole 21, a locking mechanism 24 is on the wedge 23.

[0019] Referring to FIG. 2 and FIG. 3, the frames 10 of the combinational gardening rack 1 subdivides into several vertical frames 11, several horizontal frames 12, a top frame 13 and several frame boards 14; the length of the vertical frame 11 is close to the length of the rack; the external diameter of the vertical frame 11 corresponds to the diameter of the vertical connecting holes 21 of the combining connectors 20; the combining connectors 20 (as shown in FIG. 2 and FIG. 4) is in horizontal rod shape in the present a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com