Knuckle arm

a technology of knuckle and knuckle, which is applied in the field of knuckle arms, can solve the problems of high manufacturing cost and particularly burdensome knuckle arms, and achieve the effect of convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

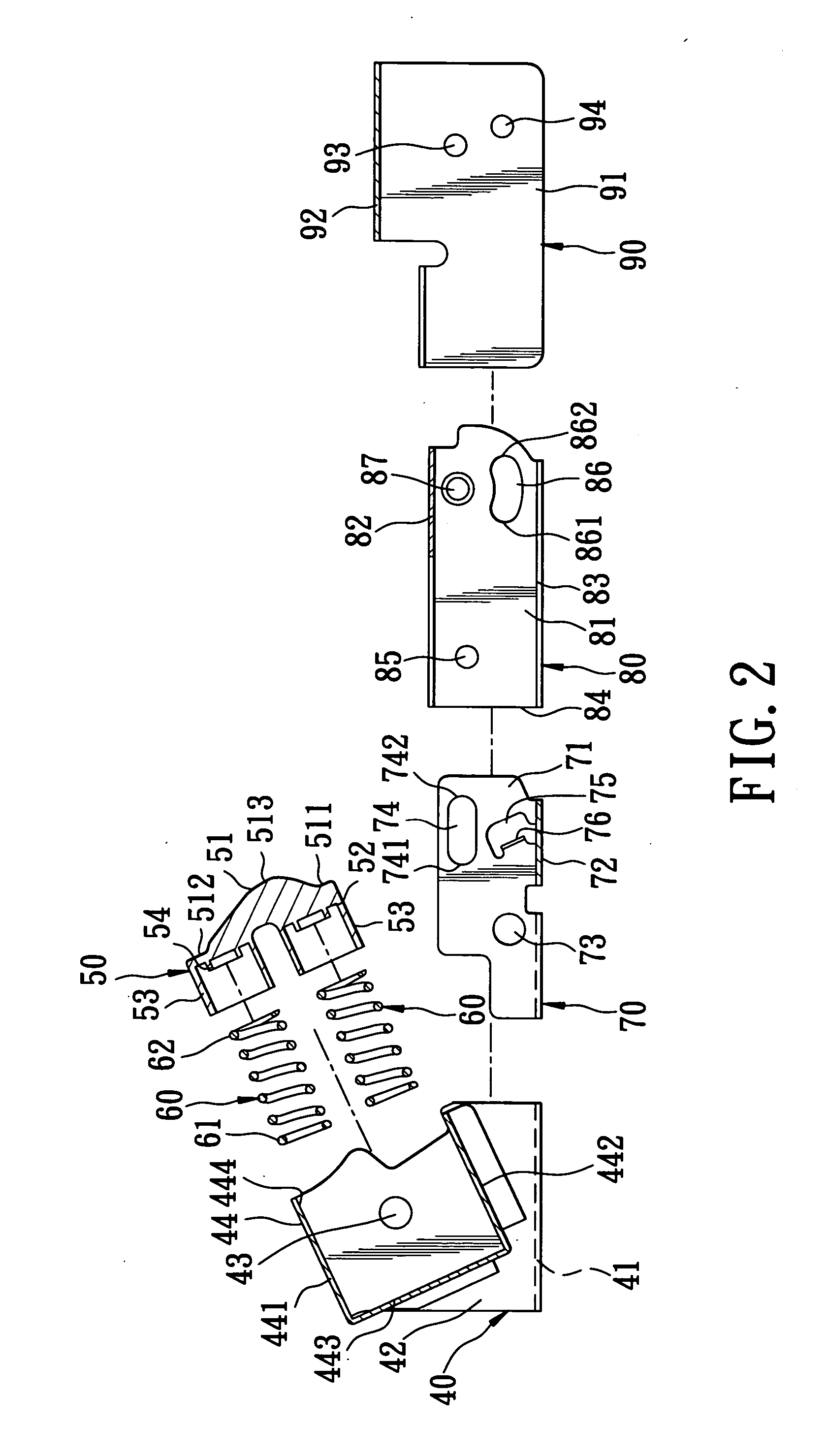

[0039] Referring to FIGS. 2 and 8, the preferred embodiment of a knuckle arm according to this invention interconnects a machine body 31 and a top cover 32 of an office machine 30, and is constructed so as to allow for the opening and closing of the top cover 32 relative to the machine body 31. The office machine may be a copier, scanner, etc.

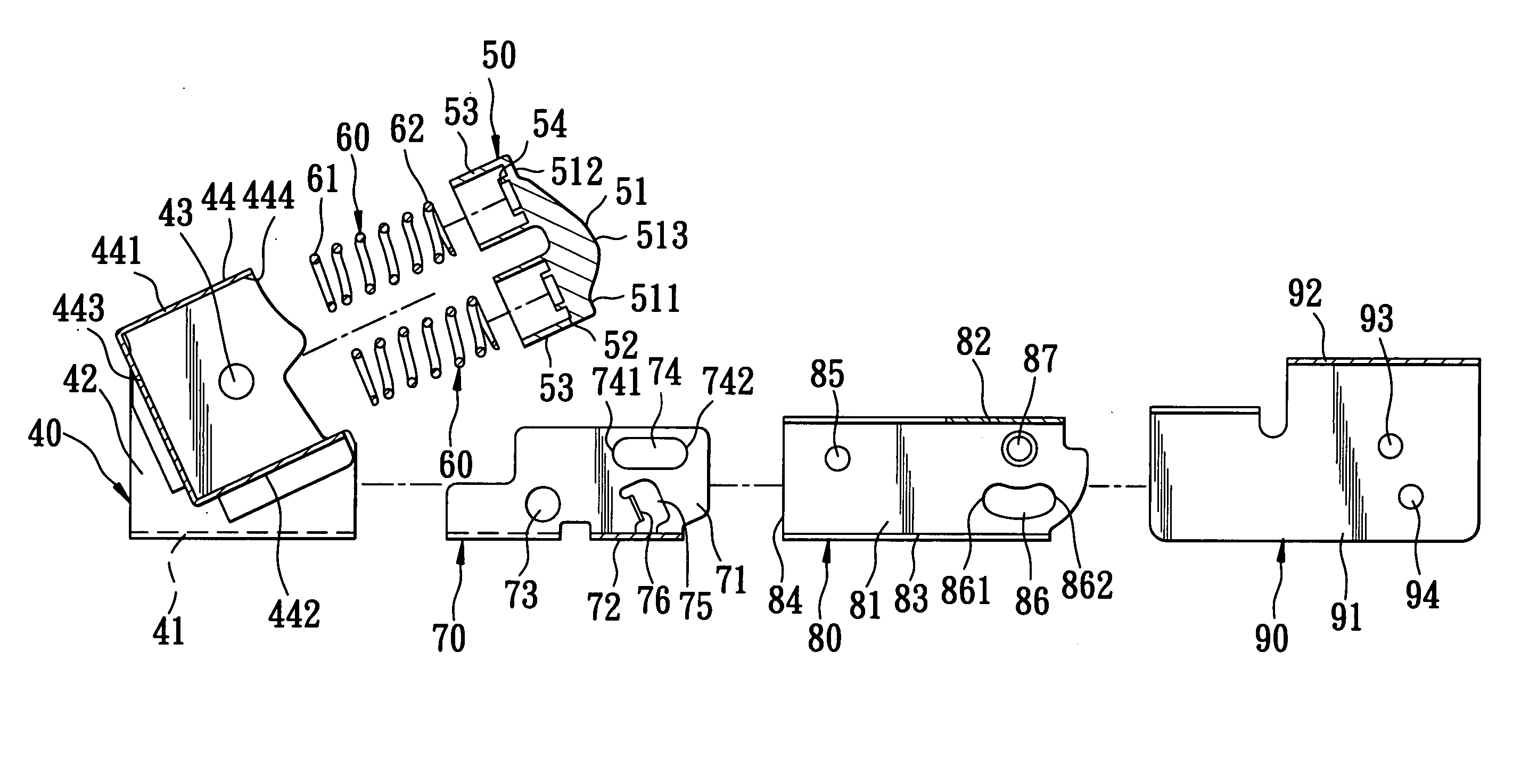

[0040] The knuckle arm includes a base 40, an inner sliding seat 50 disposed slidably within the base 40, four resilient members 60 (only two are shown in FIGS. 2 and 8) disposed between the base 40 and the inner sliding seat 50, a first pivotable seat 70 disposed pivotally on the base 40, a pressing rod 100 extending through the first pivotable seat 70 and kept in contact with a cam surface 51 of the inner sliding seat 50, a second pivotable seat 80 sleeved on the first pivotable seat 70, a third pivotable seat 90 disposed pivotally on the second pivotable seat 80, a first pivot rod 101 extending through the second pivotable seat 80 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com