Method of monitoring the filling of a washing machine drum with water

a washing machine and water filling technology, applied in the field of monitoring the filling of the washing machine drum, can solve the problems of a selected washing program being terminated, and the possibility of a child being hurt or injured by such movements, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.

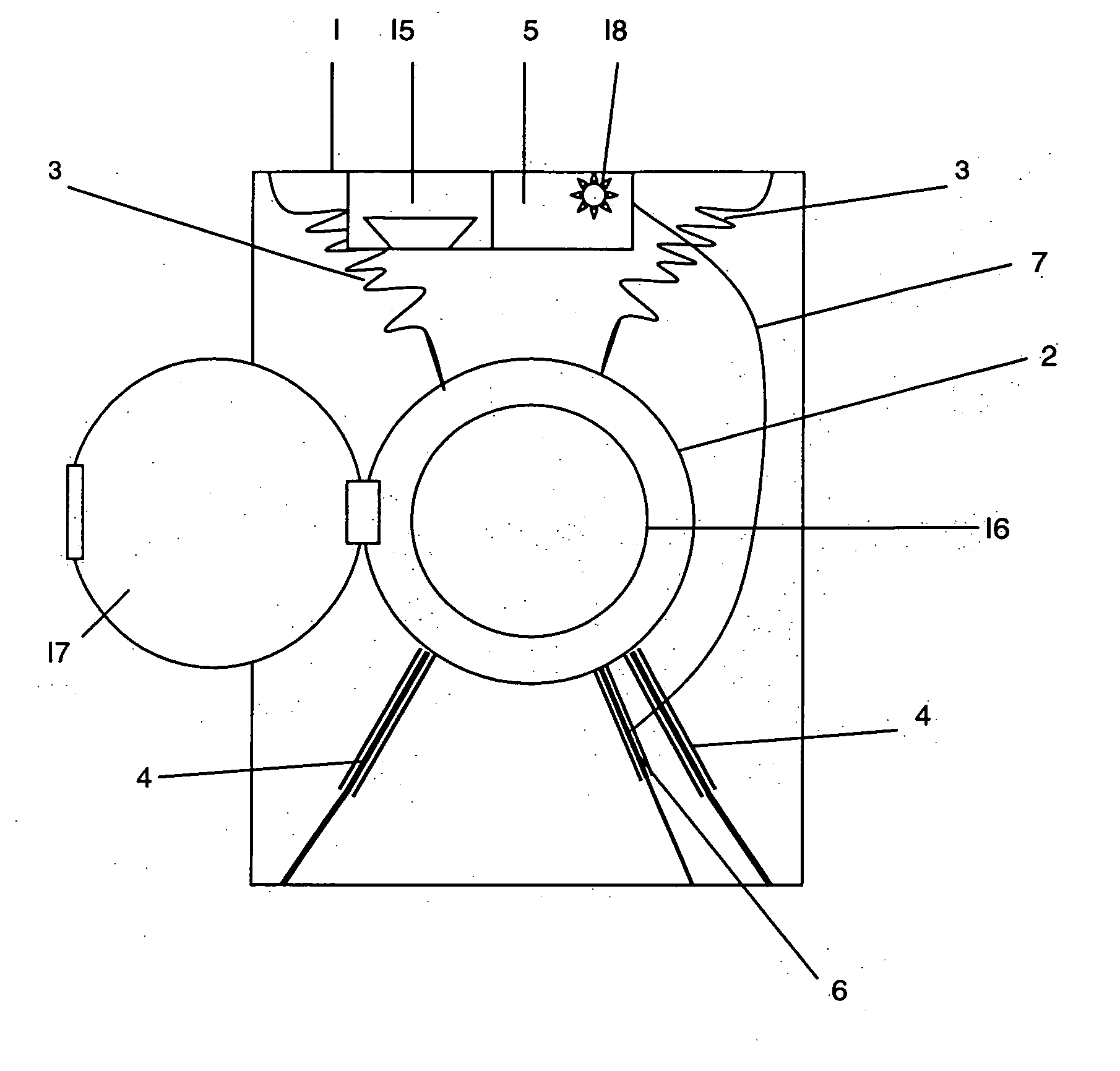

[0023] As schematically shown in FIG. 1, the washing aggregate or washing fluid tub 2 is suspended by springs 3 for oscillatory movements within the housing 1 of a washing machine housing from housing components not shown. The washing aggregate consists of a washing fluid tub 2 and a drum 16 mounted for rotary movement within the tub 2. Rotary movement is at times imparted to the drum 16 by a motor 19 by way of a belt drive. Shock absorbers 4 are provided to prevent excessive oscillations in case of imbalanced loads in the drum 16. A path sensor 6 detects not only any imbalance or the condition of a load within the drum 16 but also movements of the washing aggregate 2 or of the drum 16. An evaluation unit 5 is connected by way of a connecting line 7 to the path sensor 6 to receive from it any detected values. A detergent chamber 15 is provided to receive and during a washing operation to dispense predetermined amounts of detergent and / or other washing agents. A loading opening 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com