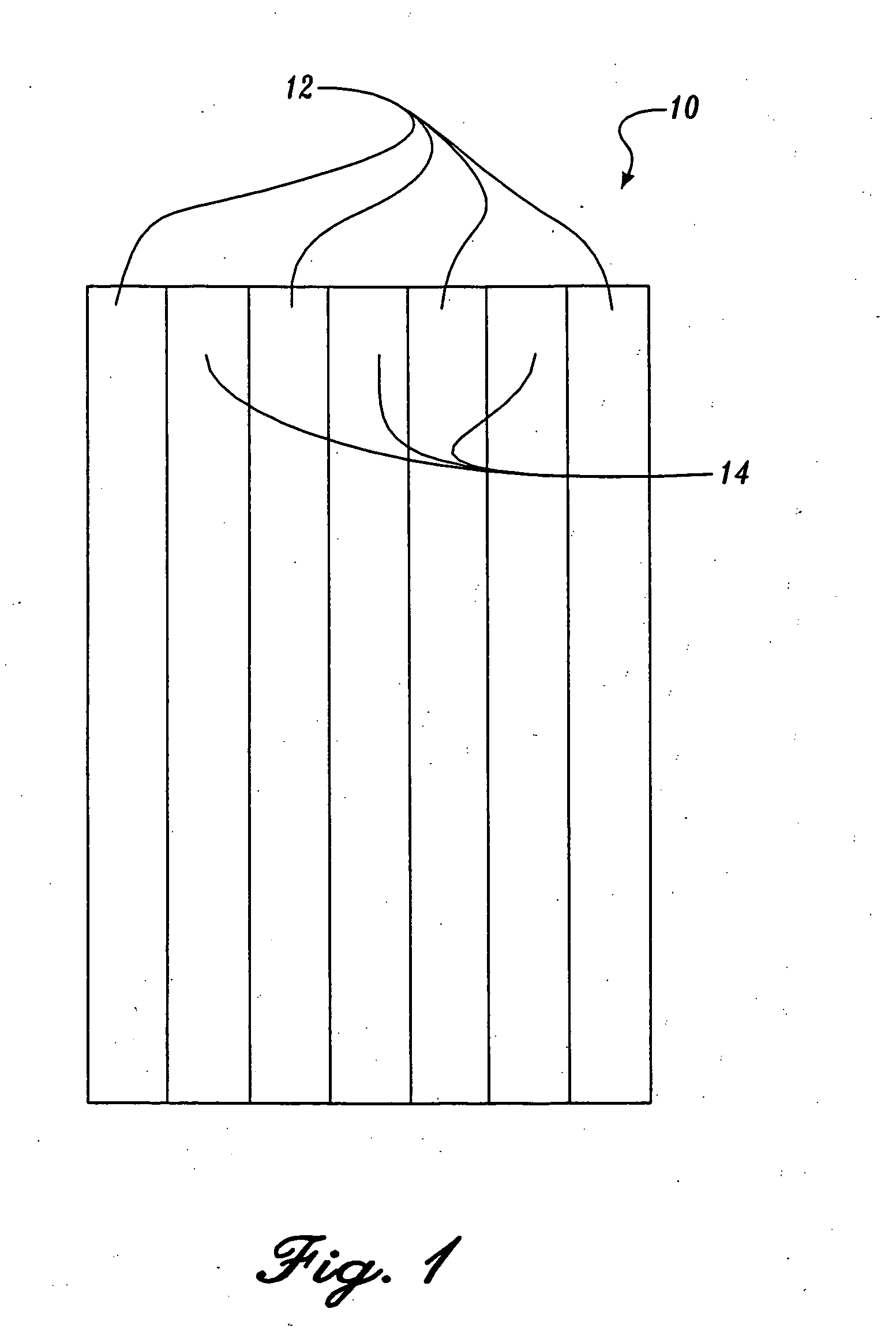

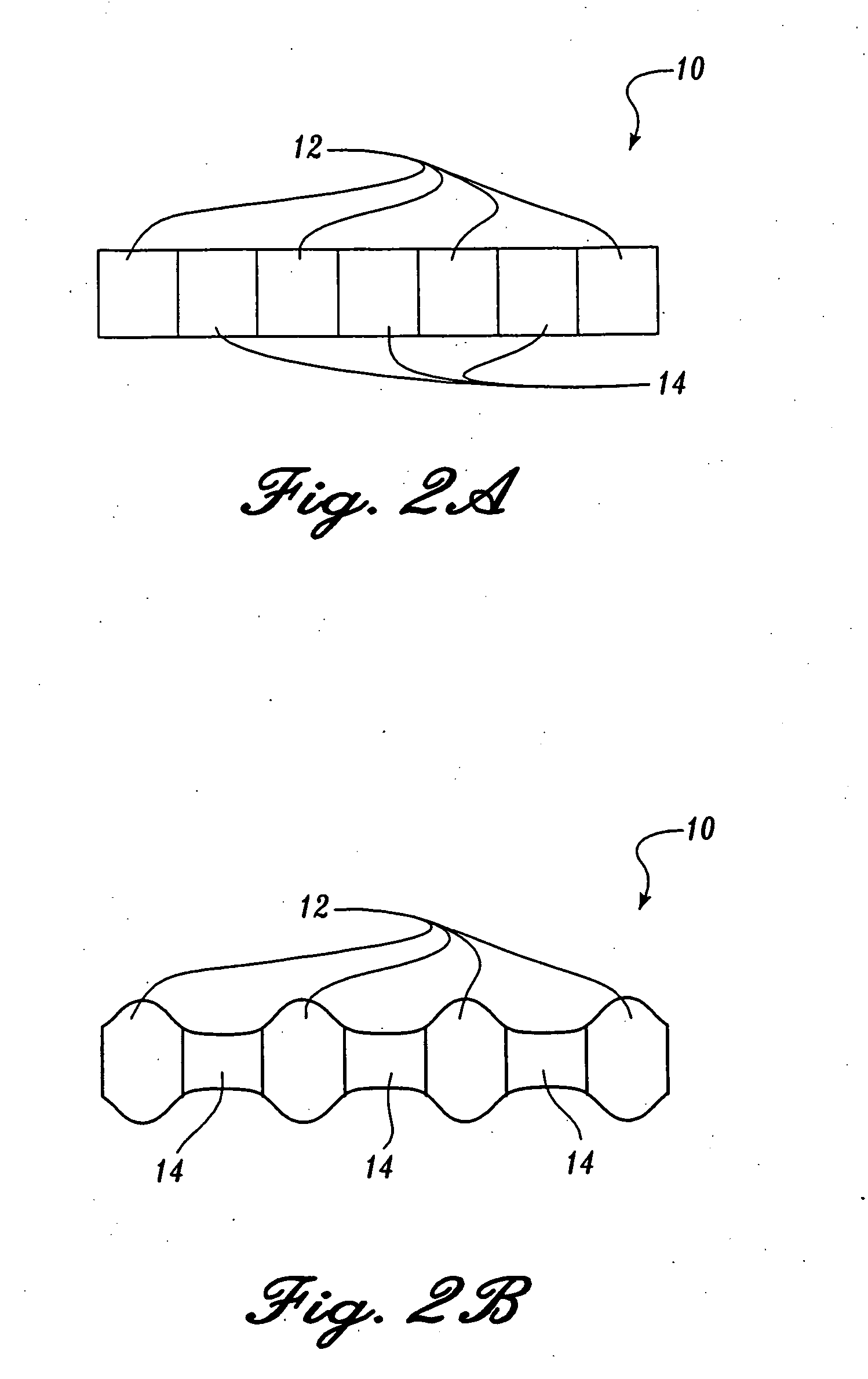

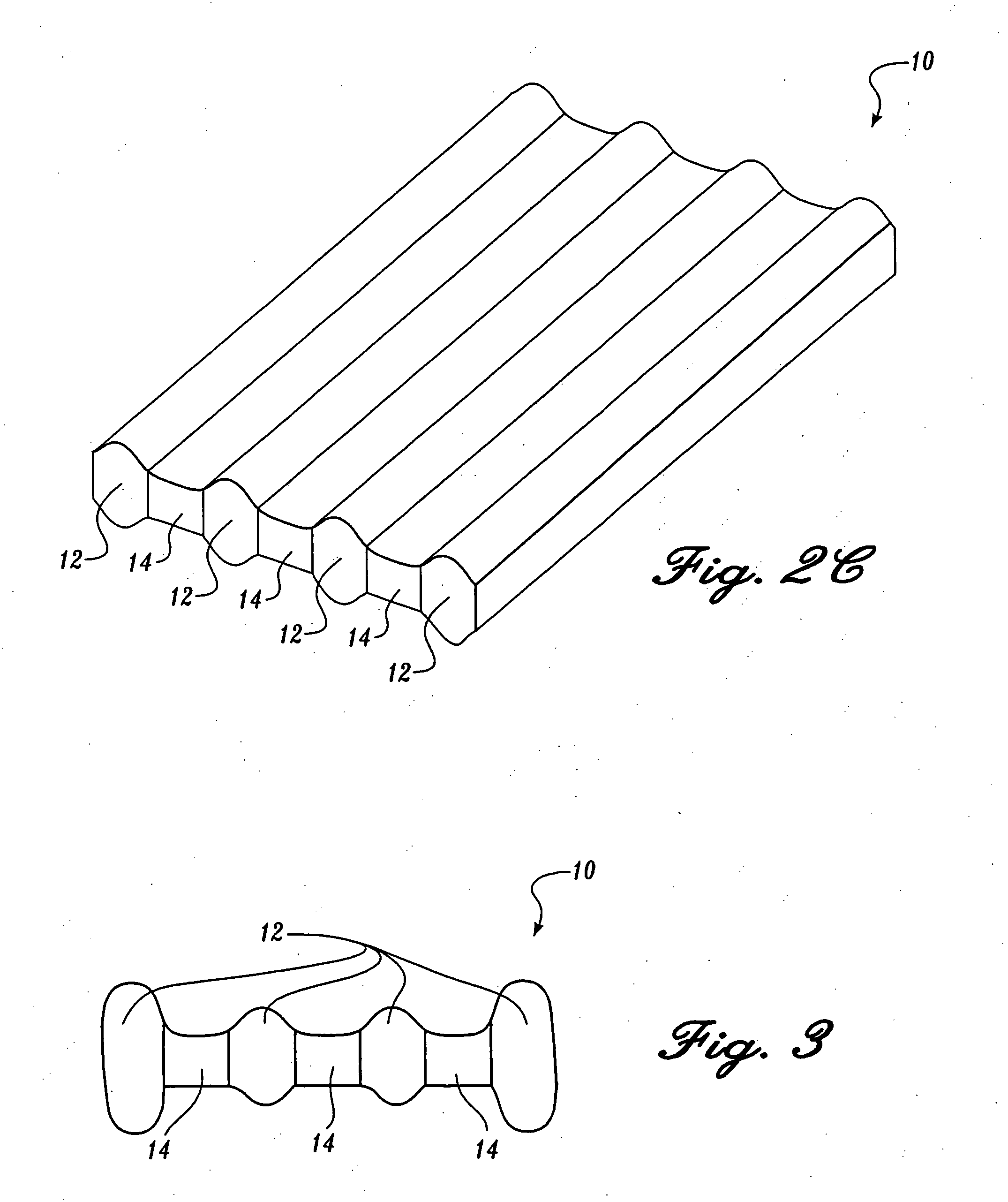

Fluted composite and related absorbent articles

a technology of absorbent composites and fluted materials, applied in the field of absorbent composites and absorbent articles, can solve the problems of gel blocking of absorbent composites that contain superabsorbent materials, requiring significant energy for their complete drying, and not being used commercially, etc., to achieve the effect of improving liquid wicking, acquisition and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Acquisition Times for a Representative Fluted Absorbent Composite

[0170] In this example, the acquisition time for a representative fluted absorbent composite of the present invention (Composite A) is compared to a commercially available diaper (Diaper A, Kimberly-Clark). Also included in the comparison is an absorbent composite (Composite B) having a composition similar to the composite of the invention and composed of fibers (50:50 crosslinked fibers and southern pine pulp fibers), wet strength agent, and absorbent material distributed relatively uniformly throughout the composite. The formation of Composite B is described in provisional U.S. patent application Ser. No. 60 / 046,395, filed May 13, 1997, and international application Serial No. PCT / US98 / 09682, filed May 12, 1998, assigned to Weyerhaeuser Company, each expressly incorporated herein by reference.

[0171] The tests were conducted on commercially available diapers (Kimberly-Clark) from which the core and surge management ...

example 2

Acquisition Rate and Rewet for Representative Fluted Absorbent Composites

[0176] In this example, the acquisition time and rewet of representative fluted absorbent composites of the present invention (designated Composites A1-A4) are compared to a commercially available diaper (Diaper A, Kimberly-Clark). Composites A1-A4 differ by the method by which the composites were dried. Also included in the comparison are a series of absorbent composites (Composites B1-B4) formed as described above for Composite B in Example 1 and differing by the method by which they were dried.

[0177] Certain properties of the tested composites including the amount of superabsorbent polymeric material (weight percent SAP) in the composite and basis weight for each of the composites are summarized in Table 2.

[0178] The tests were conducted on commercially available diapers (Kimberly-Clark) from which the cores were removed and used as surrounds for the fluted absorbent composites and for Composites B1-B4. T...

example 3

Horizontal and Vertical Wicking for a Representative Fluted Absorbent Composite

[0187] In this example, the wicking characteristics of a representative fluted absorbent composite (Composite A) are compared to a commercially available diaper storage core (Diaper B, Procter & Gamble) and a wet-laid storage core having absorbent material distributed uniformly throughout the composite (Composite B).

[0188] The horizontal wicking test measures the time required for liquid to horizontally wick preselected distances. The test is performed by placing a sample composite on a horizontal surface with one end in contact with a liquid bath and measuring the time required for liquid to wick preselected distances. Briefly, a sample composite strip (40 cm×10 cm) is cut from a pulp sheet or other source. If the sheet has a machine direction, the cut is made such that the 40 cm length of the strip is parallel to the machine direction. For absorbent composites of the invention, the strip is centered s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com