Slatwall section and assembly

a technology of slatwall and assembly, which is applied in the field of slatwall sections, can solve the problems of difficult interlocking of adjacent slatwall sections and not being aesthetically pleasing, and achieve the effect of improving the aesthetics of the slatwall assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

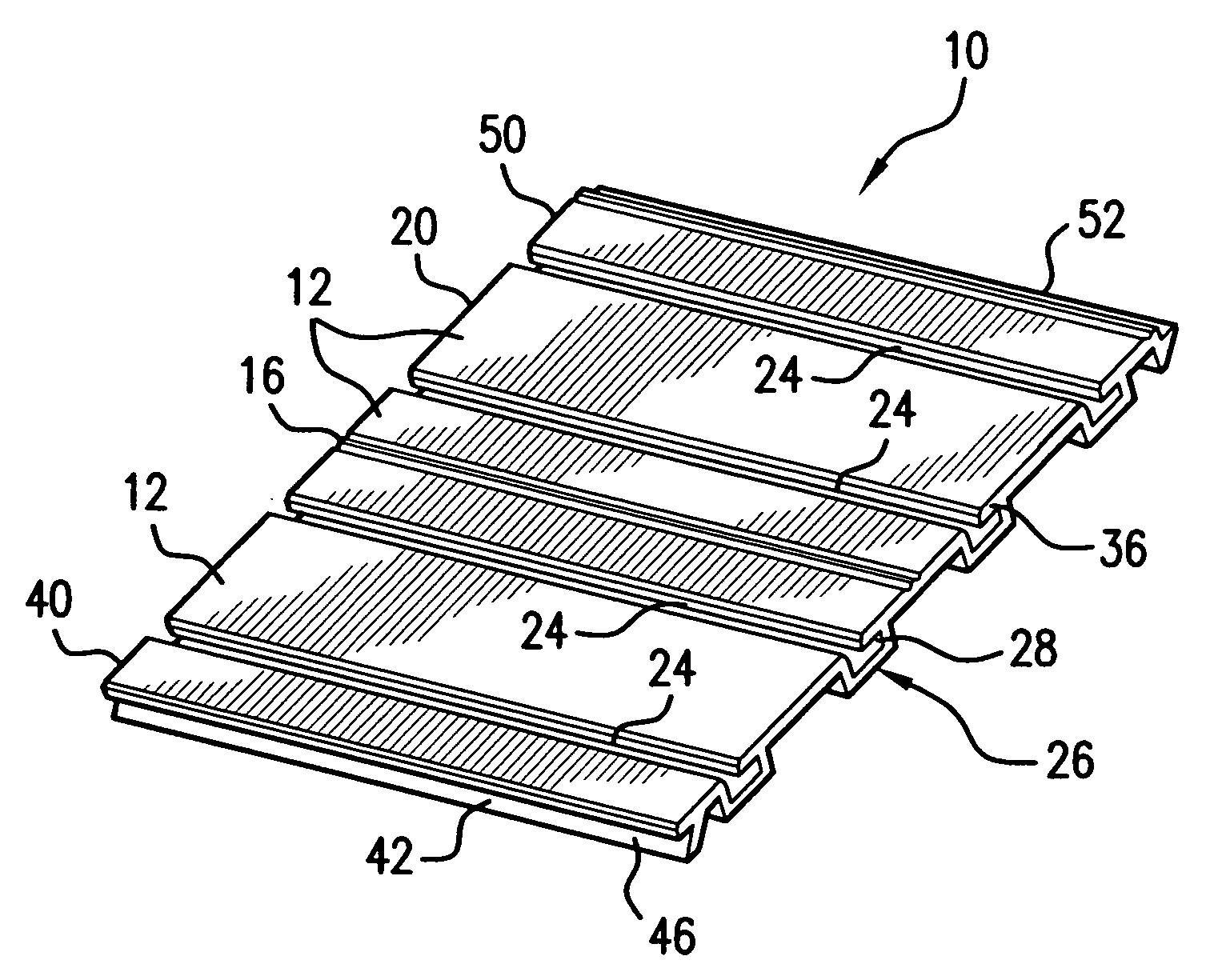

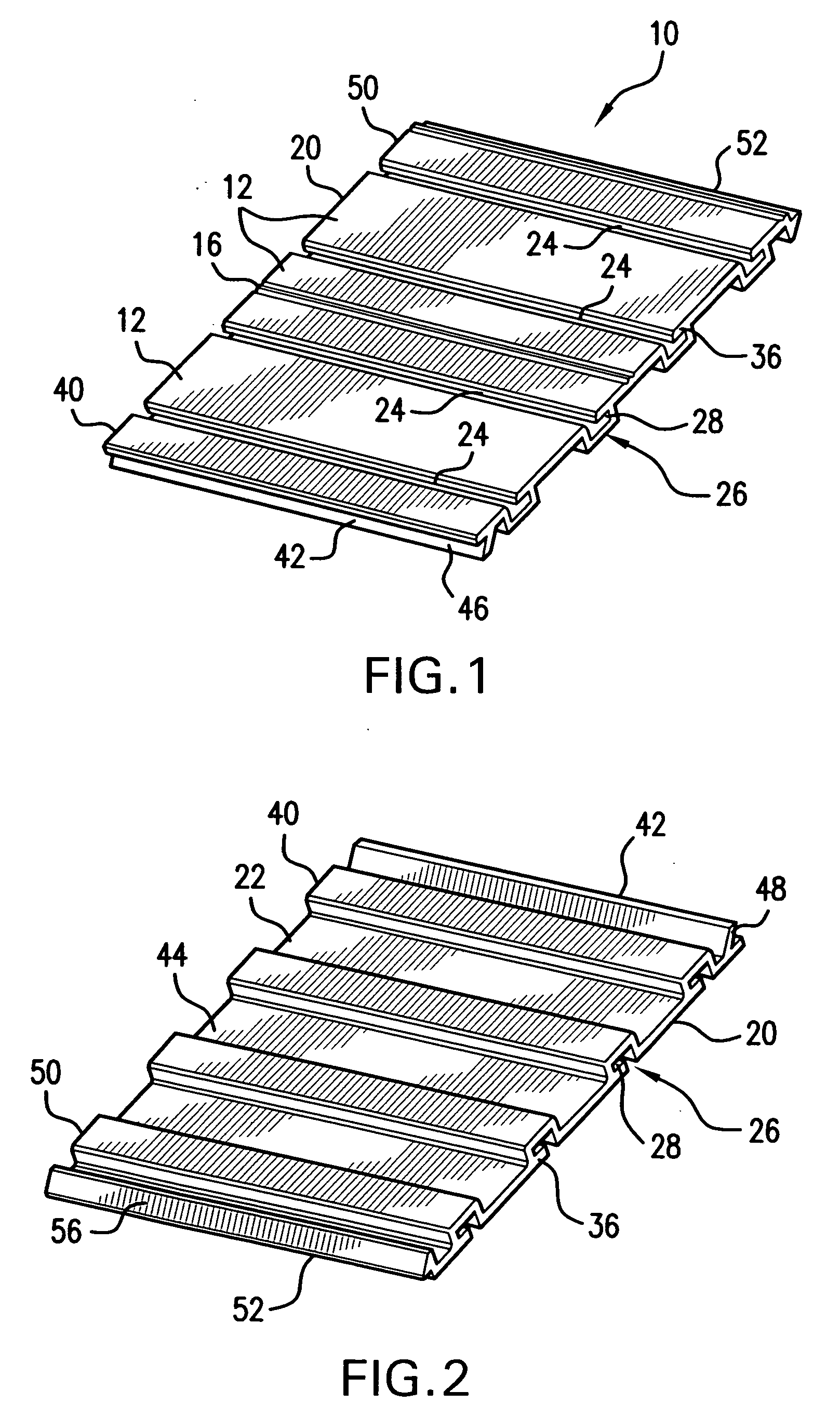

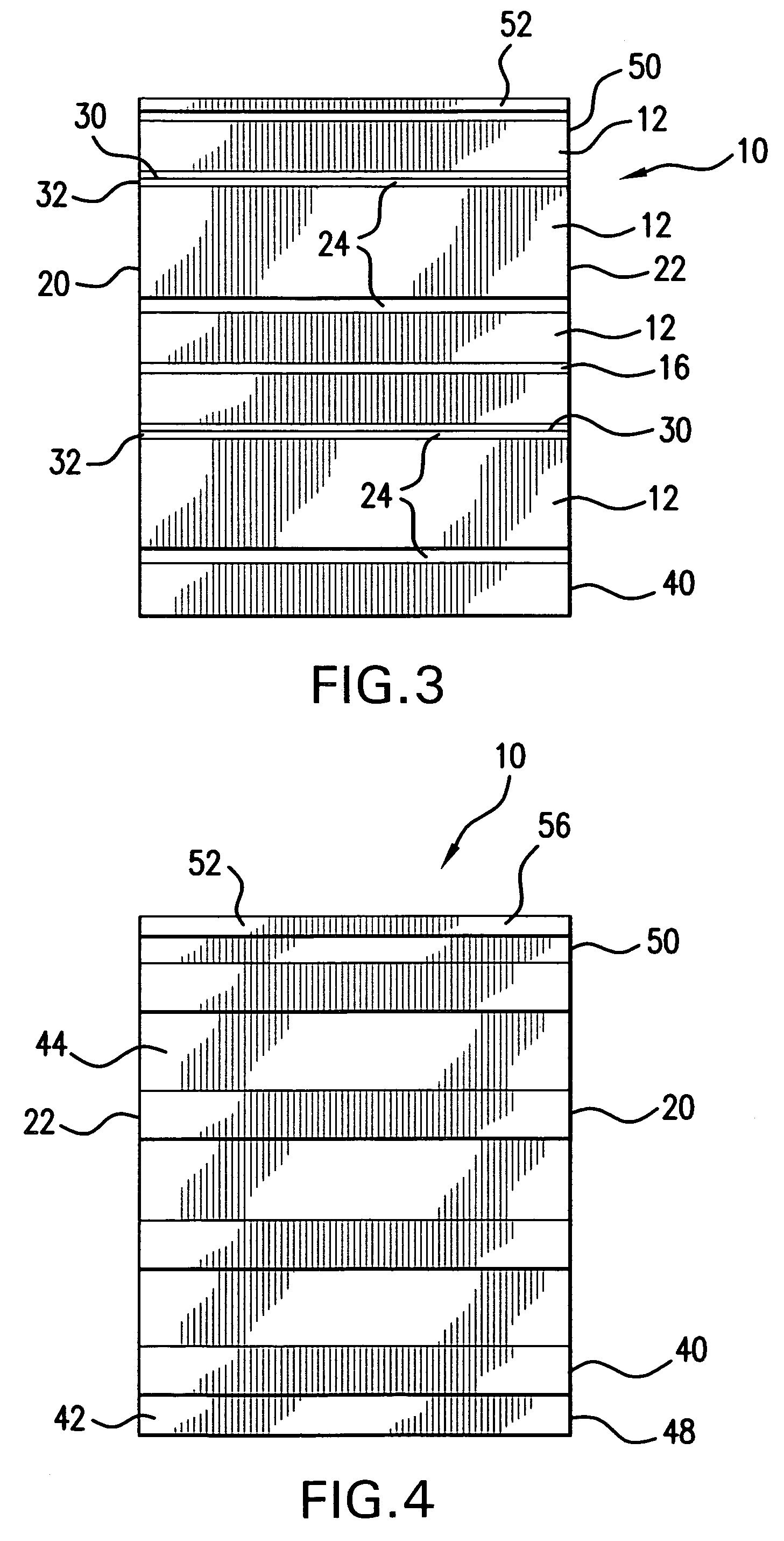

[0023] Referring to FIGS. 1-8, the present invention provides a slatwall section 10 and a slatwall assembly including a plurality of mateably engageable slatwall sections. Slatwall section 10 can be made of any suitable material, such as a plastic, metal, alloy and / or composite material, using any suitable manufacturing process known to those skilled in the art and guided by the teachings herein provided. In one preferred embodiment of this invention, slatwall section 10 is formed of an extruded plastic material. Slatwall section 10 can be fastened or attached to a support wall100 using any suitable fastener, such as a screw. A second slatwall section 10′ can be mateably engaged with slatwall section 10 and fastened to support wall 100 to form or construct the slatwall assembly, as discussed in more detail below.

[0024] Slatwall section 10 forms or includes a plurality of parallel frontal wall segments 12 which collectively form a front surface 14 of slatwall section 10. Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com