Mid-sole

a midsole and foot technology, applied in the field of footwear, can solve the problems of insufficient shock absorption of 26 mm, unstable column structure, etc., and achieve the effects of smooth transition of force, reduced force, and reduced for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

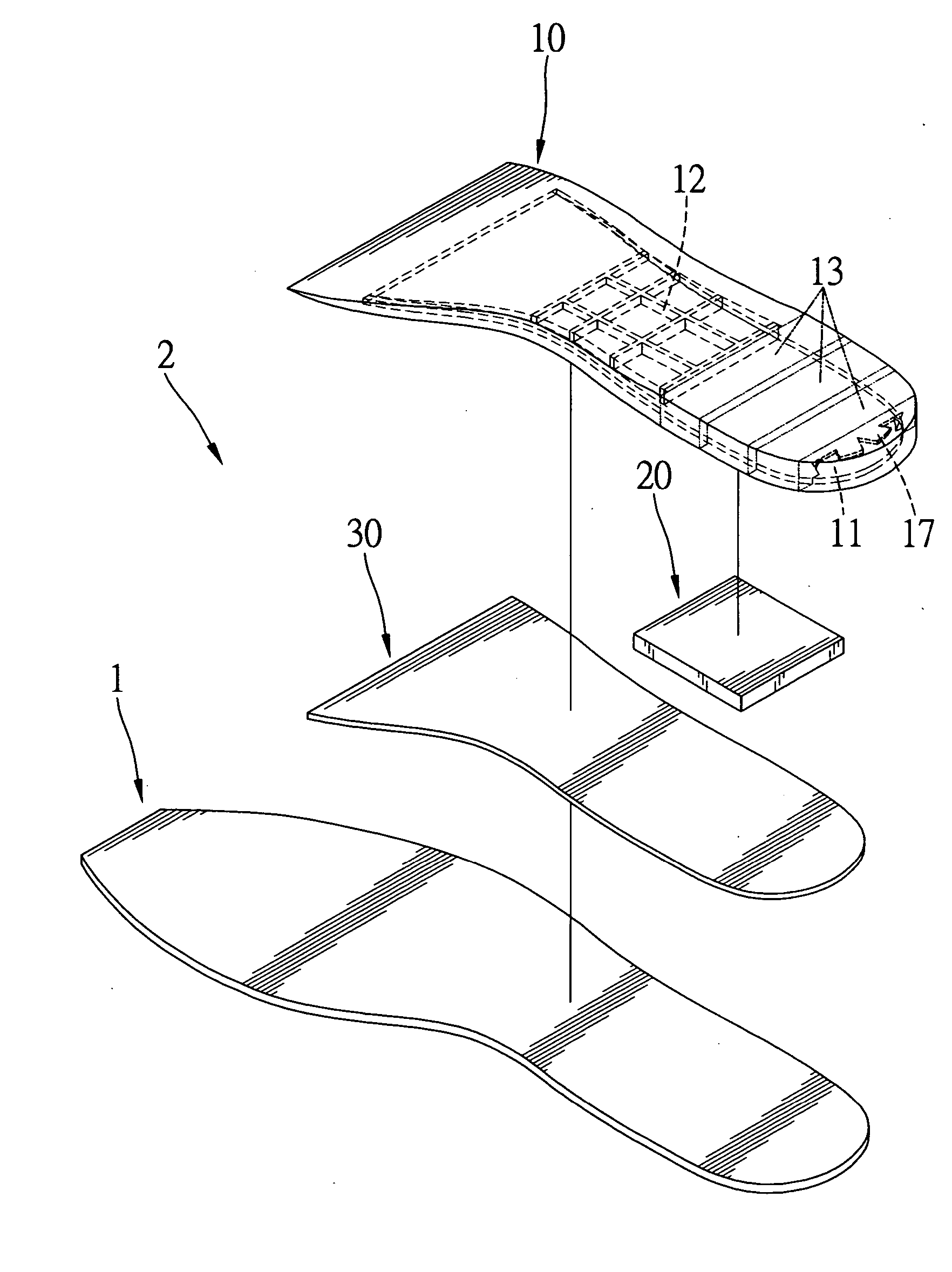

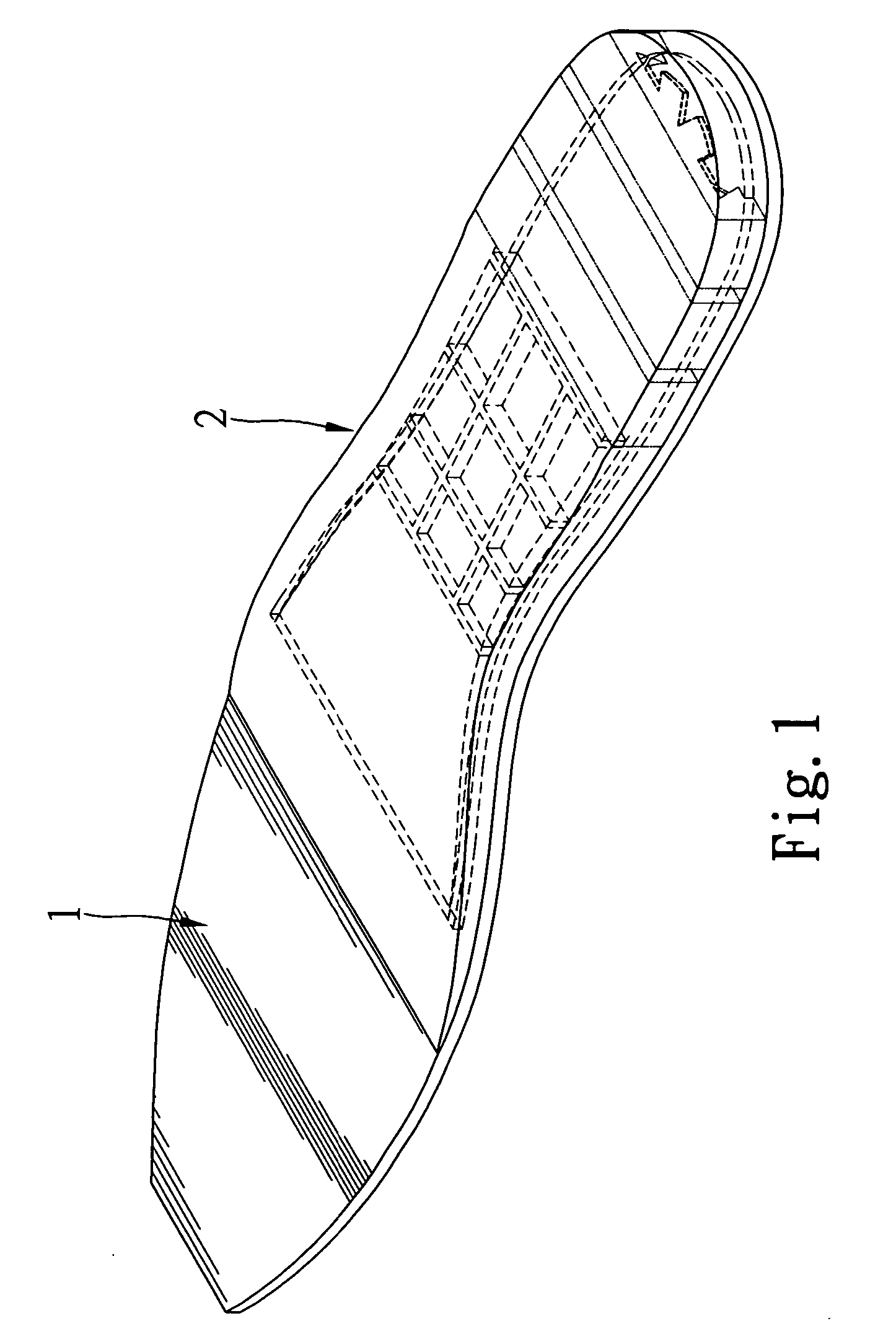

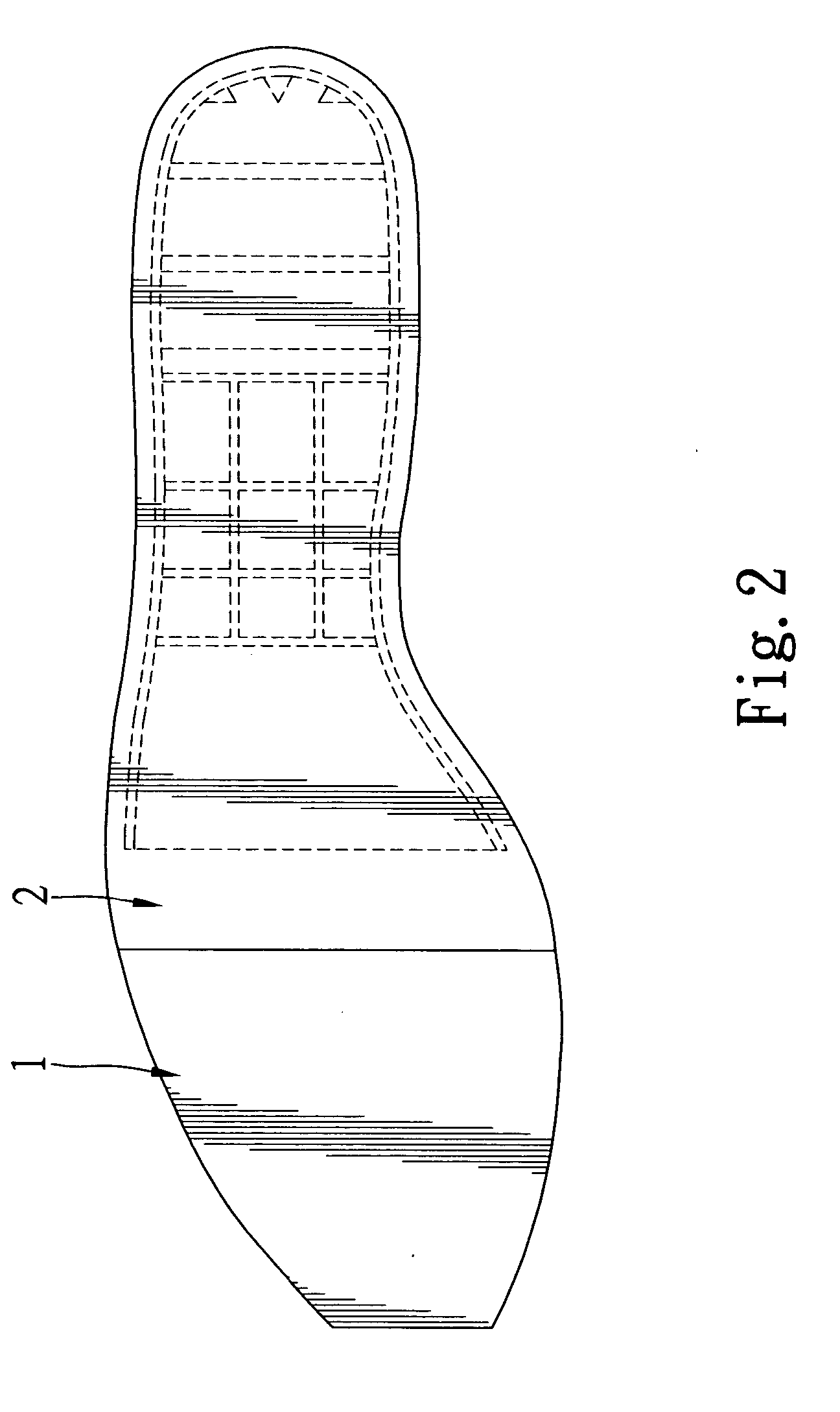

[0014] Referring to FIGS. 1 and 2, according to a first embodiment of the present invention, a sole assembly includes a sole 1 and a mid-sole 2 provided on the sole 1. The sole 1 is longer than the mid-sole 2.

[0015] Referring to FIG. 3, the mid-sole 2 includes a cap 10, an elastic pad 20 put. in the cap 10 and a cover 30 for sealing the elastic pad 20 in the cap 10.

[0016] The cap 10 is made of an elastic material with predetermined modulus of elasticity. The cap 10 defines a space 11 that faces down. A plurality of ribs 12 projects from the ceiling of the space 11 near a middle portion of the cap 10. The ribs 12 become like a grid, which is intended for prevention of distortion and provision of stability. A plurality of buffers 13 projects from the ceiling of the space 11 near a rear portion of the cap 10. Referring to FIG. 4, each of the buffers 13 includes two columns 14, a beam 15 extending from one of the columns 14 to the other of the columns 14 and two reinforcement elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com