Microbicidal air filter

a technology of air filters and microorganisms, applied in the field of air filters, can solve the problems of inhalation of hazardous to users, inability to capture and kill bacteria, and suffer from the design of the above-mentioned, so as to reduce the difficulty and disadvantages, capture and kill, and without significant loss of antimicrobial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

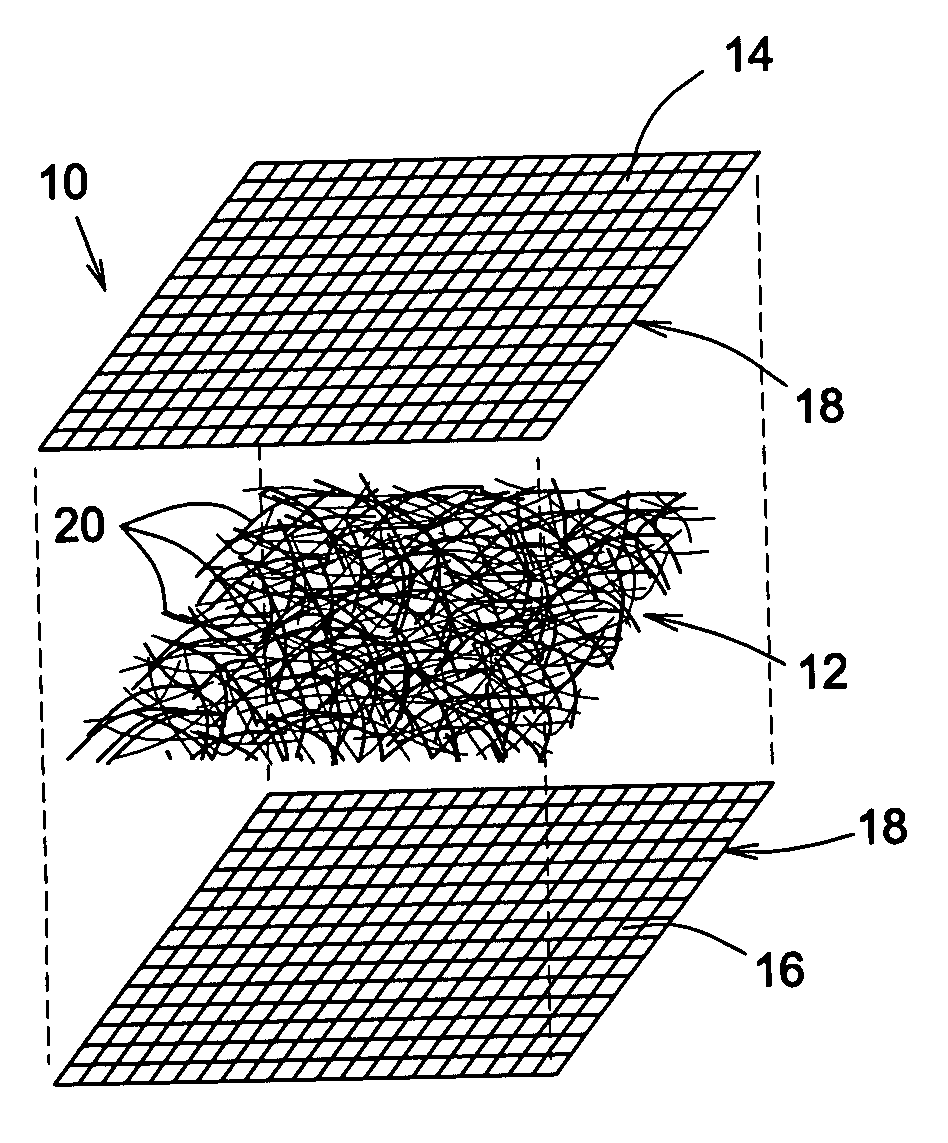

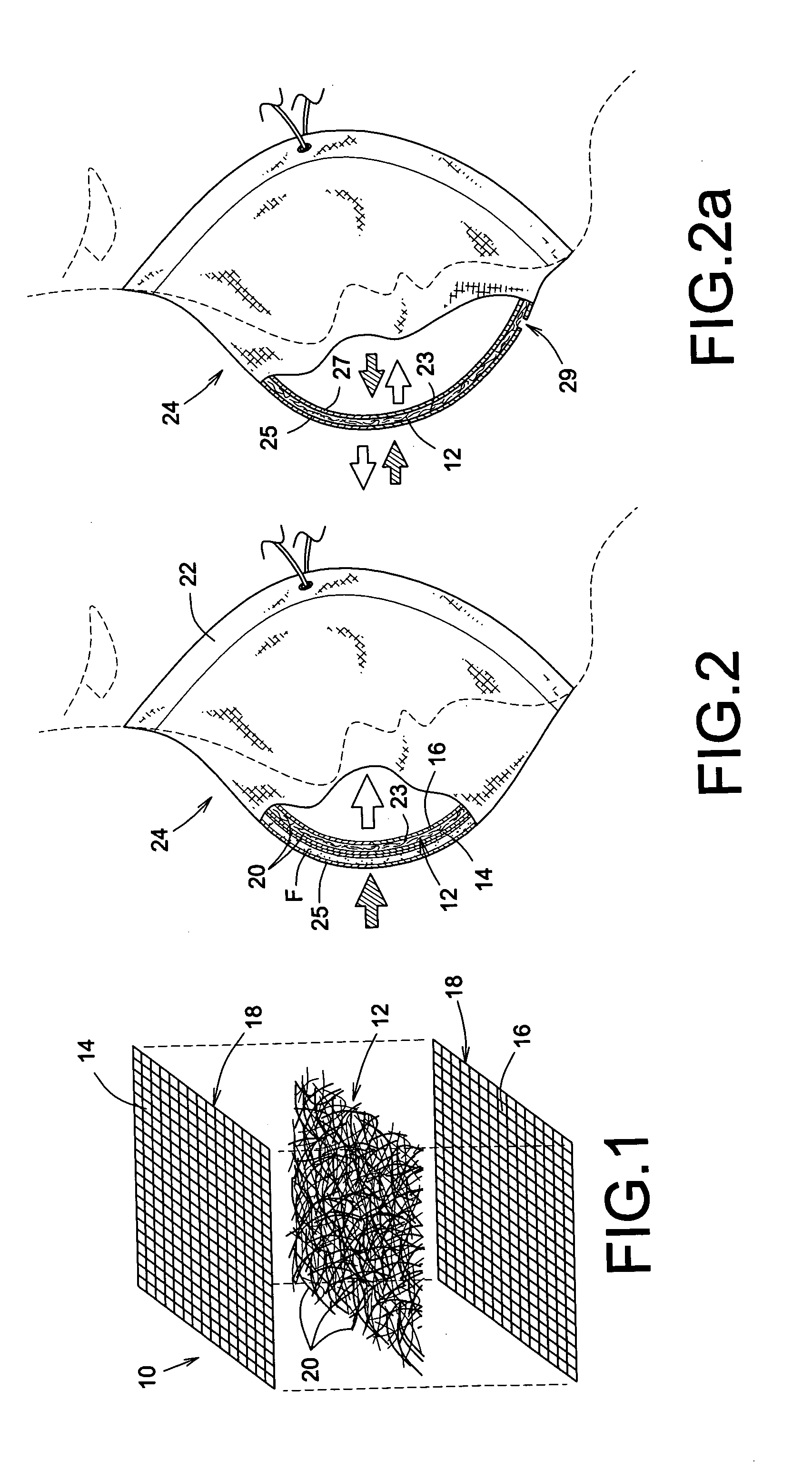

Evaluation of Microbicidal and Filtering Capacity of Rigid and Soft Facemasks

[0065] As shown in Table 1, two facemasks of the present invention were compared to a commercially available facemask1,2,3 for their antimicrobial and retaining capabilities against a panel of bacteria and molds of various sizes4,5,6,7. The NB rigid and soft masks used in Examples 1 and 2 were both equipped with a network 12 of PVC based organic fiber containing molecularly bonded triclosan. The NB soft mask was composed of a double covering of woven type fabric containing 76% w / w THERMOVYL-ZCB™ fibers and 24% w / w polyester (although any other woven type fabric such as cotton or the like could have been used) stitched to each other at their periphery, within which the network 12 was located (see FIG. 2a above). The NB rigid mask was made of two conventional commercially available anti-dust masks, which were inserted one inside the other, between which the network of PVC based organic fiber containing tric...

example 2

Evaluation of Filtering of Small Particles

[0067] The filtering capacity of the three masks of Example 1 was tested against two particulate materials of 0.3 μm particle size using essentially the same apparatus as in Example 1. A cartridge capturing membrane located downstream from an air pump, in this case, captured breakthrough particulates. The air pump creates a negative pressure downstream of the mask. The two particulate materials chosen were sodium chloride and dioctyl phthalate.

TABLE 2Filtration efficiency (%)Particulate materialSize (μm)NBRMNBSM3M*Sodium chloride (NaCl)0.310010095Dioctylphthalate (DOP)0.3100100

NBRM = Rigid mask

NBSM = Soft mask

*Data from technical specification2

example 3

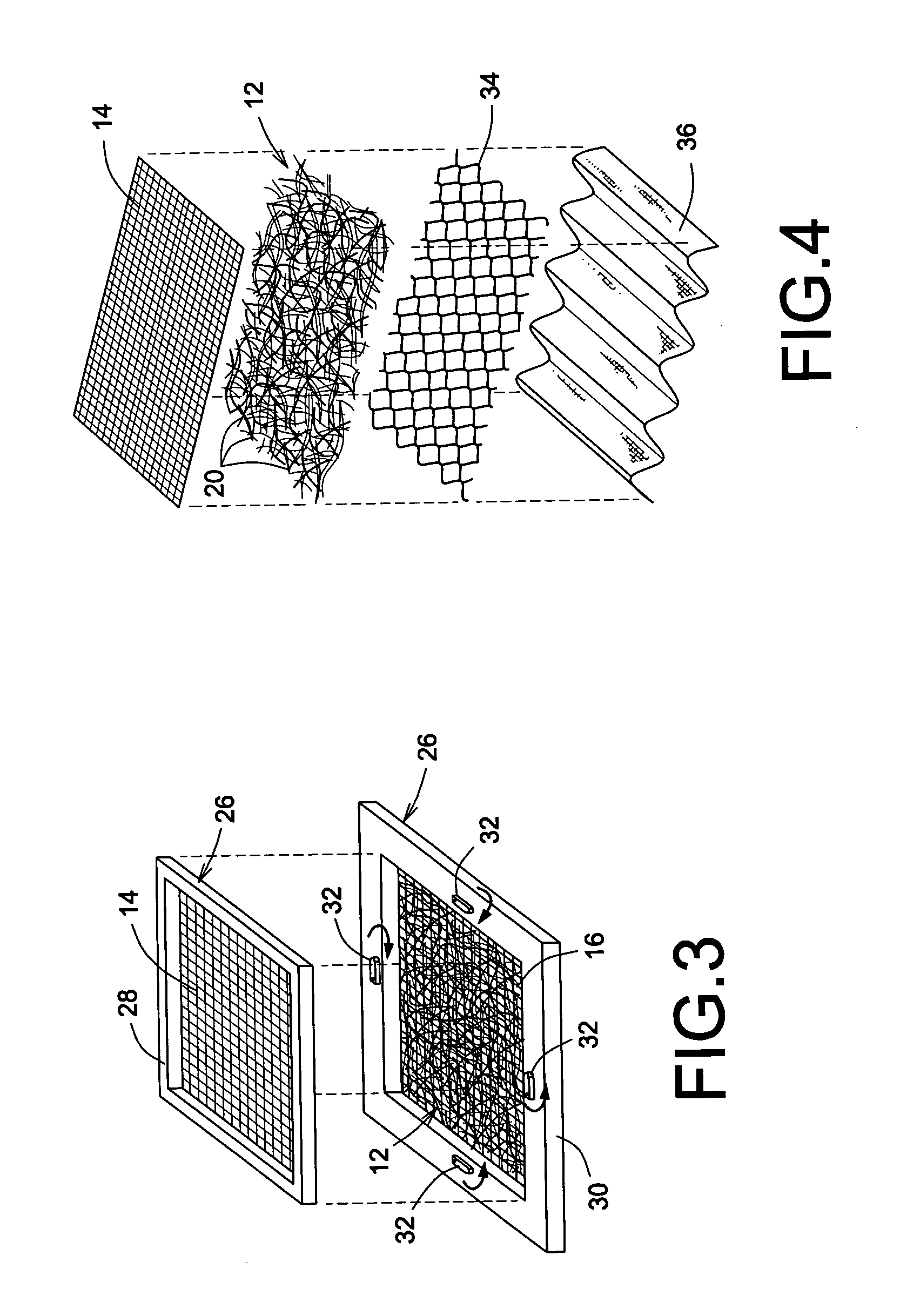

Evaluation of Microbicidal and Filtering Capacity of a Ventilation System Filter

[0068] The antimicrobial capacity of a filter of the embodiment of FIG. 3 with RHOVYL'AS+™ fibers was evaluated after 0, 7, 14, and 21 days installation in a ventilation system in a house. The results are illustrated in Tables 3 to 6 below.

[0069] The filters were removed after the aforesaid times and analysed using the Samson method10. The fibrous material (1 g) of each filter was diluted with demineralised, sterilized water (9 mL) and then serially diluted.

[0070] The calculation of total amount of bacteria, yeast and molds were done using hemacytometry. The calculation of the total amount of viable bacteria, yeasts and molds were determined following a culture of the serial dilutions on appropriate media. The aerobic viable bacteria were cultured on soya agar-agar (TSA, Quelab), whereas the yeasts and molds were cultured on HEA supplemented with gentamycin (0.005% p / v) and oxytetracycline (0.01% p / v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| air permeable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com