Water outlet tubing structure for faucets

a technology for faucets and water outlet tubing, which is applied in the direction of mechanical equipment, transportation and packaging, and functional valve types, etc. it can solve the problems of uneconomically time-consuming and effort-wasting, over-conventional water outlet tubing structure for faucets, and inefficient laborious and troublesome assembly, etc., to achieve convenient and speedy assembly, easy and speedy production, and economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

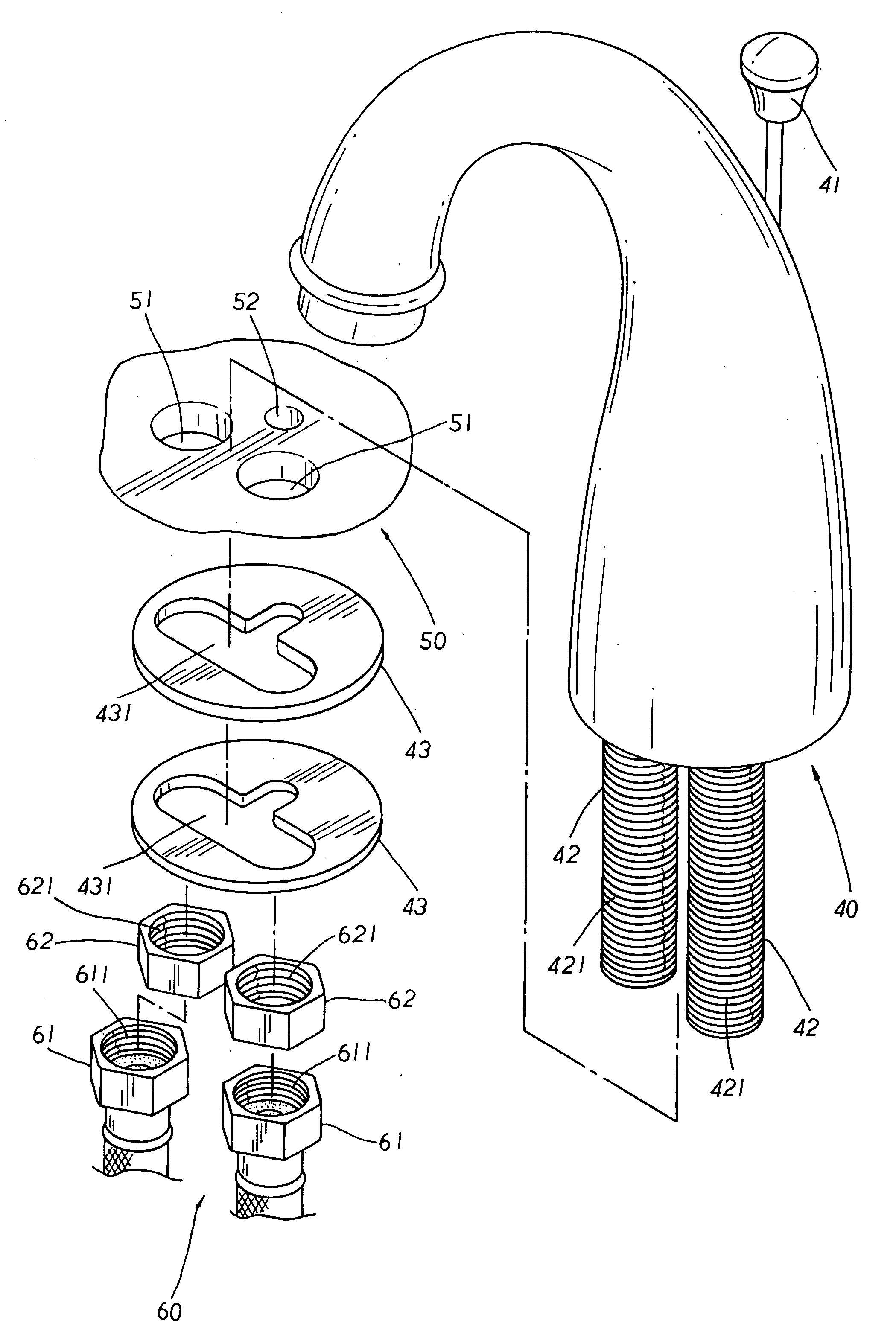

[0017] Please refer to FIG. 5. The present invention is related to a water outlet tubing structure for faucets, including a faucet body 40, a washbowl 50, and water tubes 60 wherein the faucet body 40 has a lift rod 41 properly mounted therein, and one or more than one water inlet pipes 42 with external threads 421 defined thereon protruding downwards at the bottom side thereof to be connected to the water tubes 60 thereby. A plurality of washers 43 with coupling slots 431 disposed thereon are provided for the water inlet pipes 42 and the lift rod 41 to be guided there-through respectively. The washbowl 50 is properly equipped with thru-holes 51 and a rod passage hole 52 to mate with the water inlet pipes 42 and the lift rod 41 of the faucet body 40 respectively. At the upper end of the water tube 60 is equipped with a screw fitting 61 having internal threads 611 defined therein, and one or more than one fixing nuts 62 with inner threads 621 defined therein are provided to register ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com