Diving snorkel assembly including a casing

a snorkel and assembly technology, applied in the field of diving snorkel assembly, can solve the problems of not being able to quickly and efficiently modify the assembly, requiring relatively expensive materials, and unable to meet the requirements of diving snorkeling, etc., and achieve the effect of quick and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

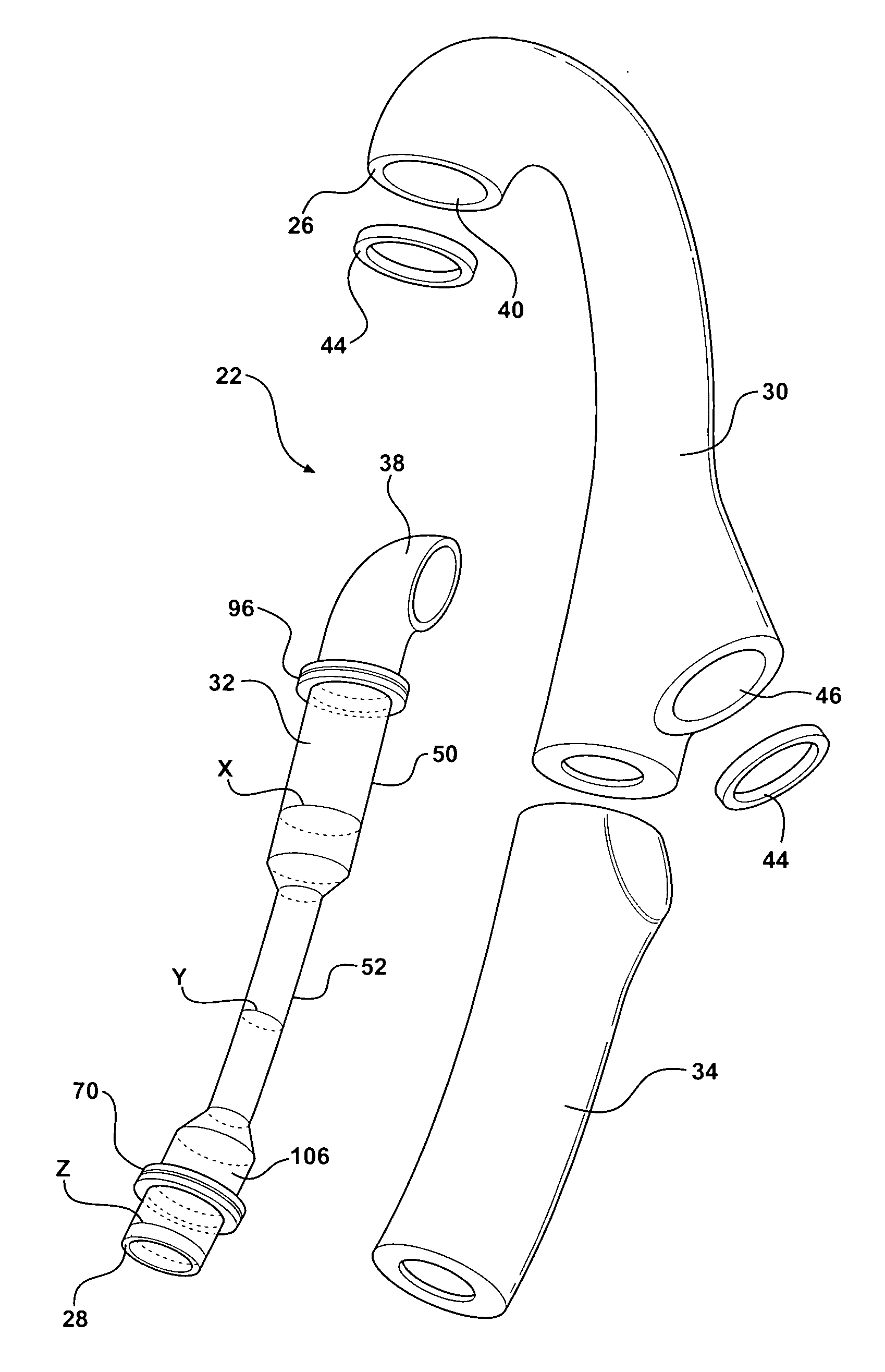

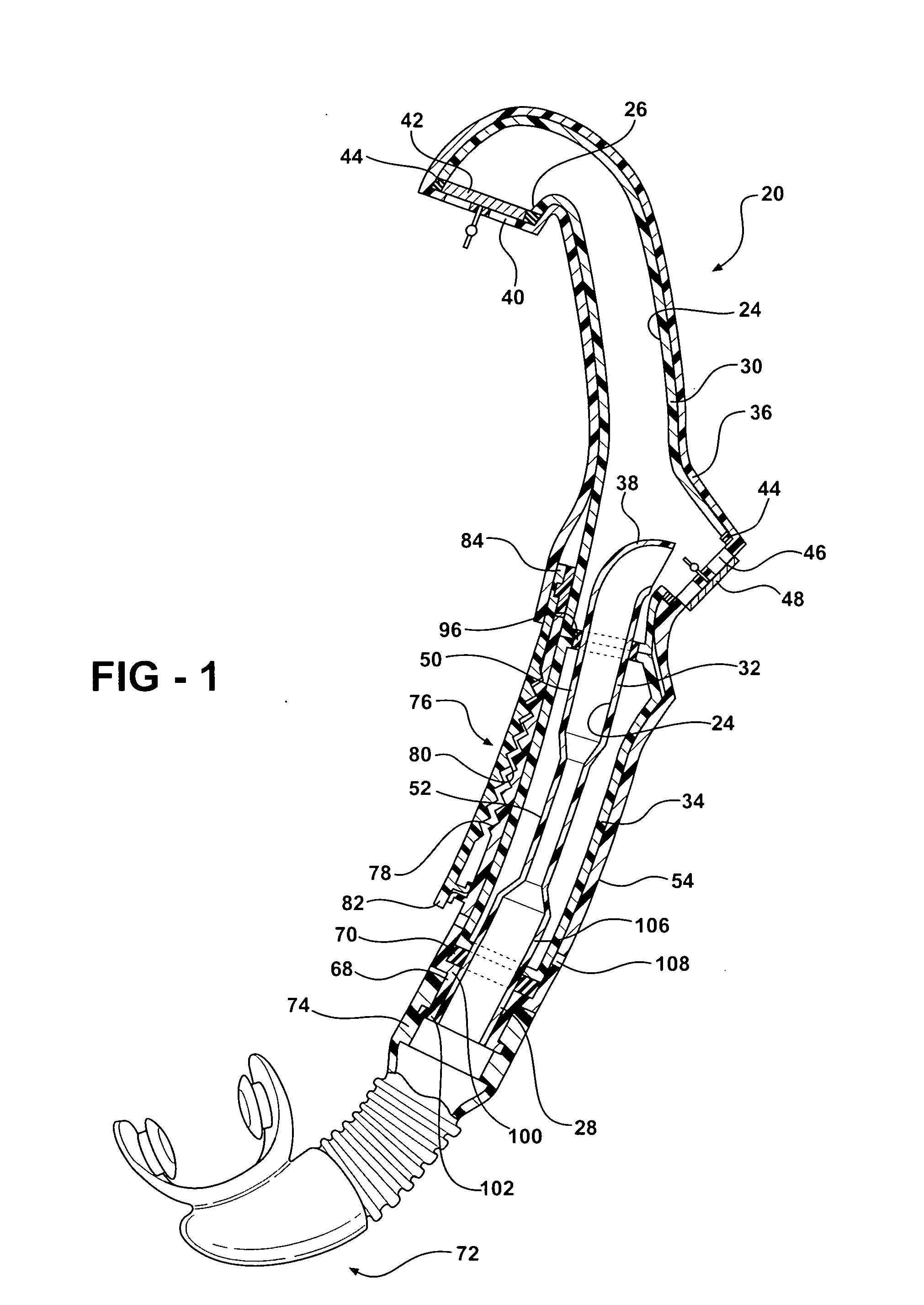

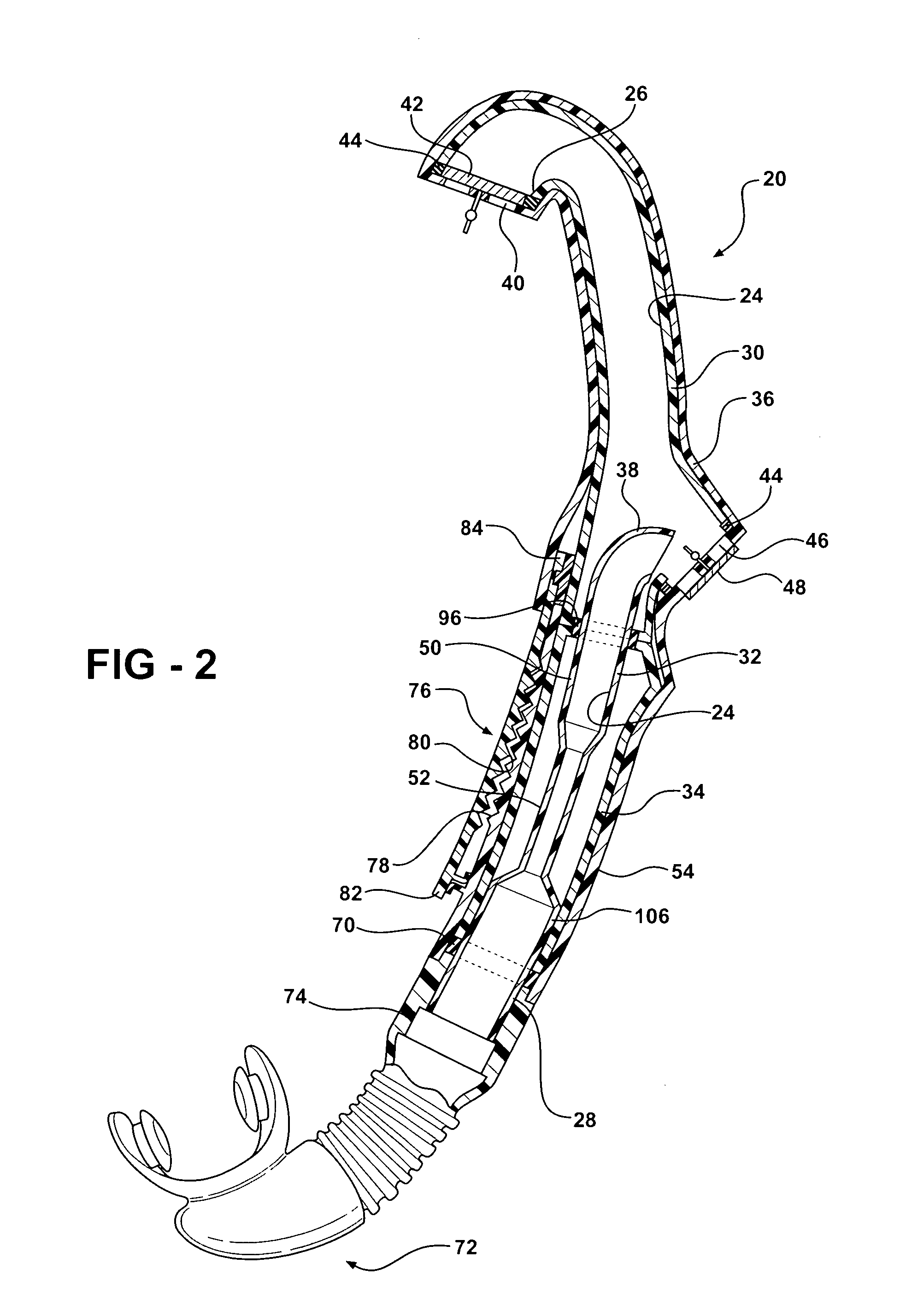

[0019] Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a diving snorkel assembly is generally shown at 20 in FIG. 1. The diving snorkel assembly 20 includes a snorkel tube 22. The snorkel tube 22 includes an inner surface 24 defining an air passageway extending between a first end 26 and a second end 28 of the snorkel tube 22. The snorkel tube 22 includes a first portion 30 and a second portion 32. Optionally, the snorkel tube 22 includes a third portion 34, as shown in FIGS. 1 and 2-4; however, it is to be appreciated that the third portion 34 may be absent from the snorkel tube 22 or, alternatively, that the snorkel tube 22 may include more than the three portions 30, 32, 34.

[0020] The snorkel tube 22, more specifically the portions 30, 32, 34 of the snorkel tube 22, may be manufactured through any method as known in the art and may be formed from any material as known in the art. At least part of the first portion 30 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com