Erosion resistant crossover for fracturing/gravel packing

a technology of fracturing/gravel packing and erosion resistance, which is applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of consuming valuable time, eroded equipment, and expensive equipment replacement or refurbishment, so as to reduce or eliminate erosion, reduce the exterior erosion of structures, and be convenient to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

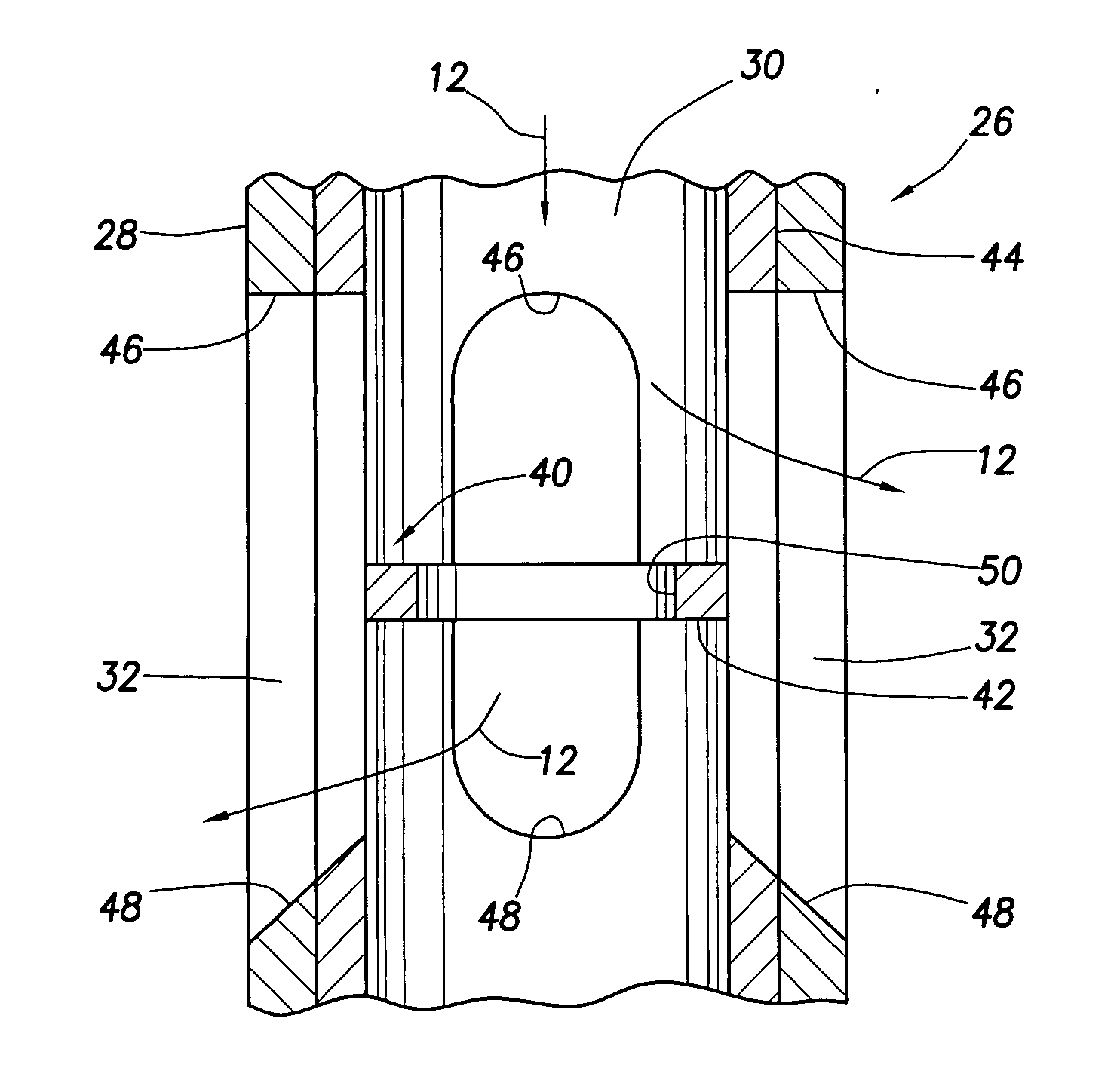

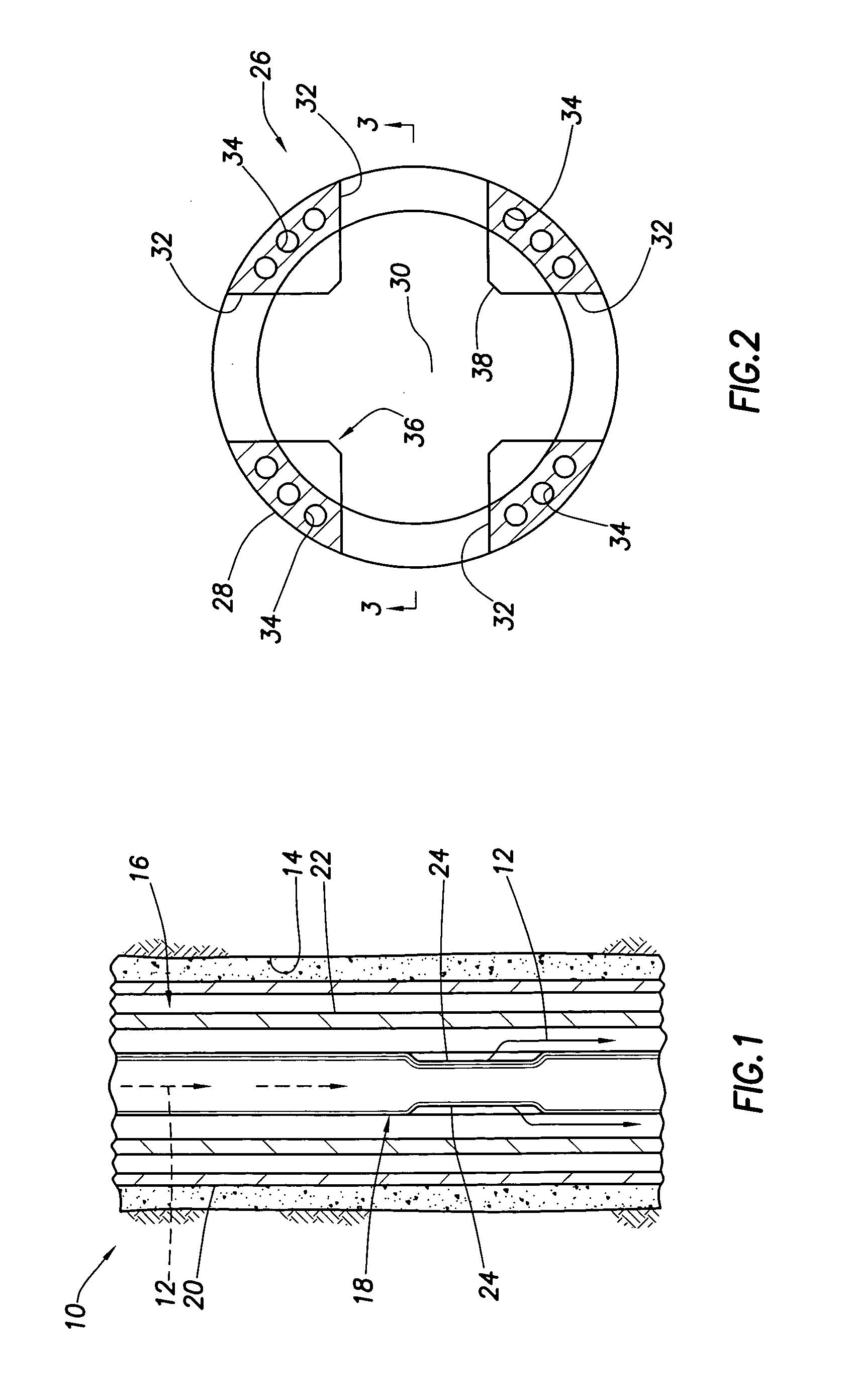

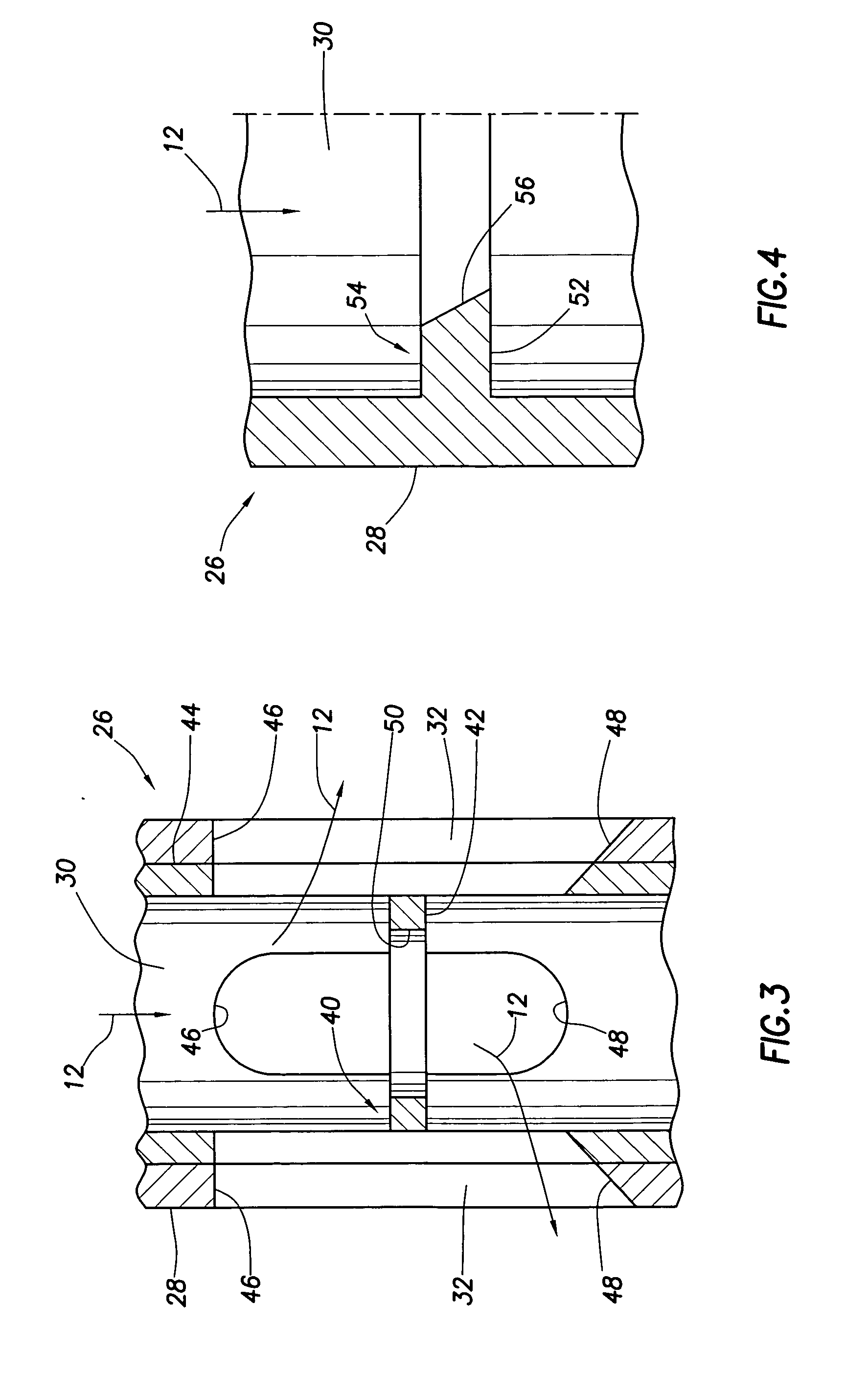

[0033] Representatively illustrated in FIG. 1 is a fluid delivery system 10 which embodies principles of the present invention. In the following description of the system 10 and other apparatus and methods described herein, directional terms, such as “above”, “below”, “upper”, “lower”, etc., are used for convenience in referring to the accompanying drawings. Additionally, it is to be understood that the various embodiments of the present invention described herein may be utilized in various orientations, such as inclined, inverted, horizontal, vertical, etc., and in various configurations, without departing from the principles of the present invention. The embodiments are described merely as examples of useful applications of the principles of the invention, which is not limited to any specific details of these embodiments.

[0034] As depicted in FIG. 1, the system 10 is being used to flow fluid (indicated by arrows 12) into a wellbore 14. The fluid 12 is flowed through a work string...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com