Lubricating oil composition with reduced phosphorus levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

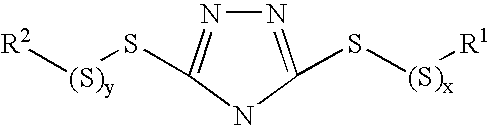

Method used

Image

Examples

example a

[0172] A preblend was prepared by blending the following materials: [0173] 150N Group II Baseoil, 92.1 wt. %; [0174] an ashless dispersant concentrate, 4.92 wt. %; [0175] an overbased detergent concentrate containing calcium, 1.85 wt. %; [0176] a neutral detergent concentrate containing calcium, 0.51 wt. %; and [0177] a secondary zinc dialkyldithiophosphate, 0.62 wt.

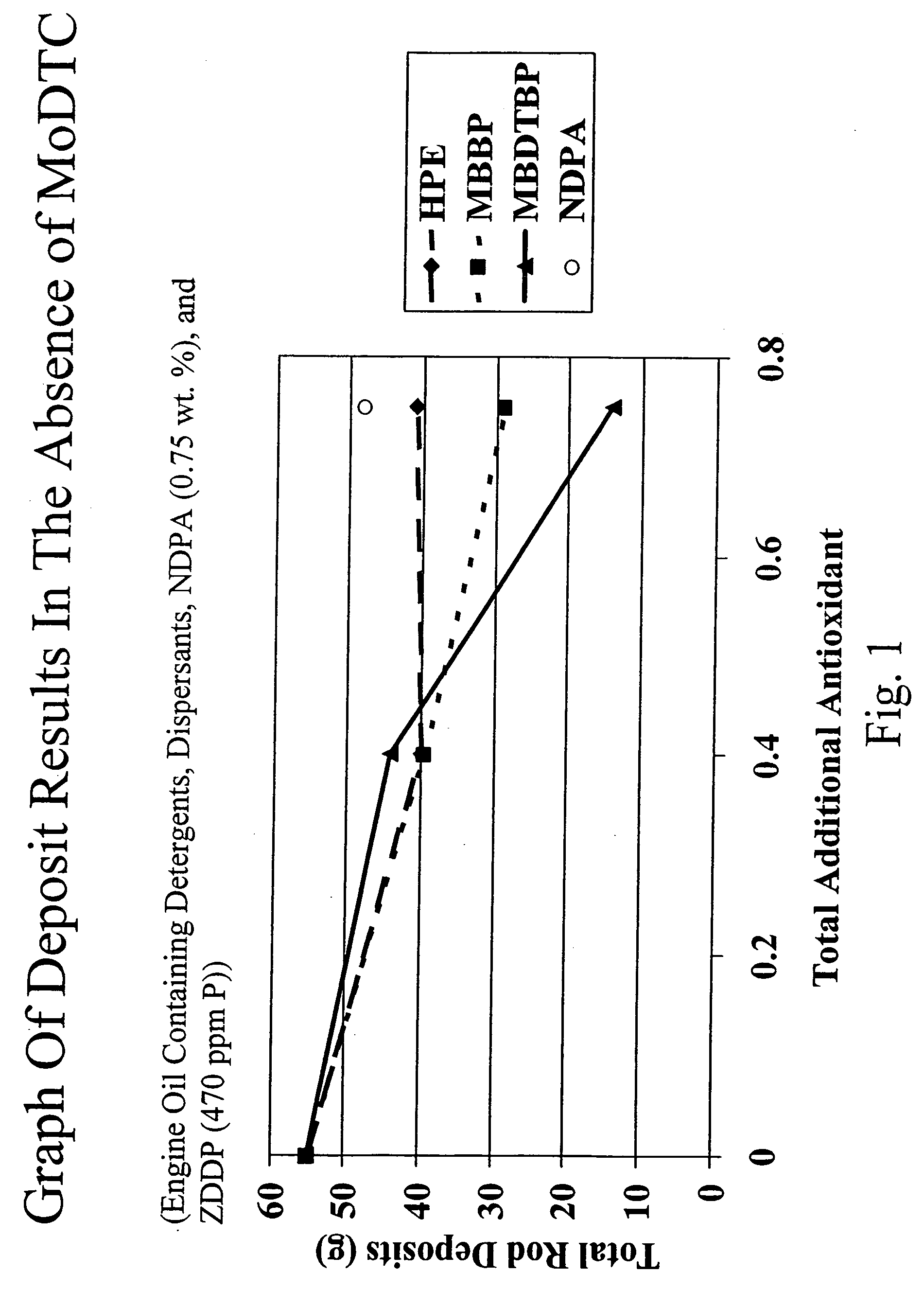

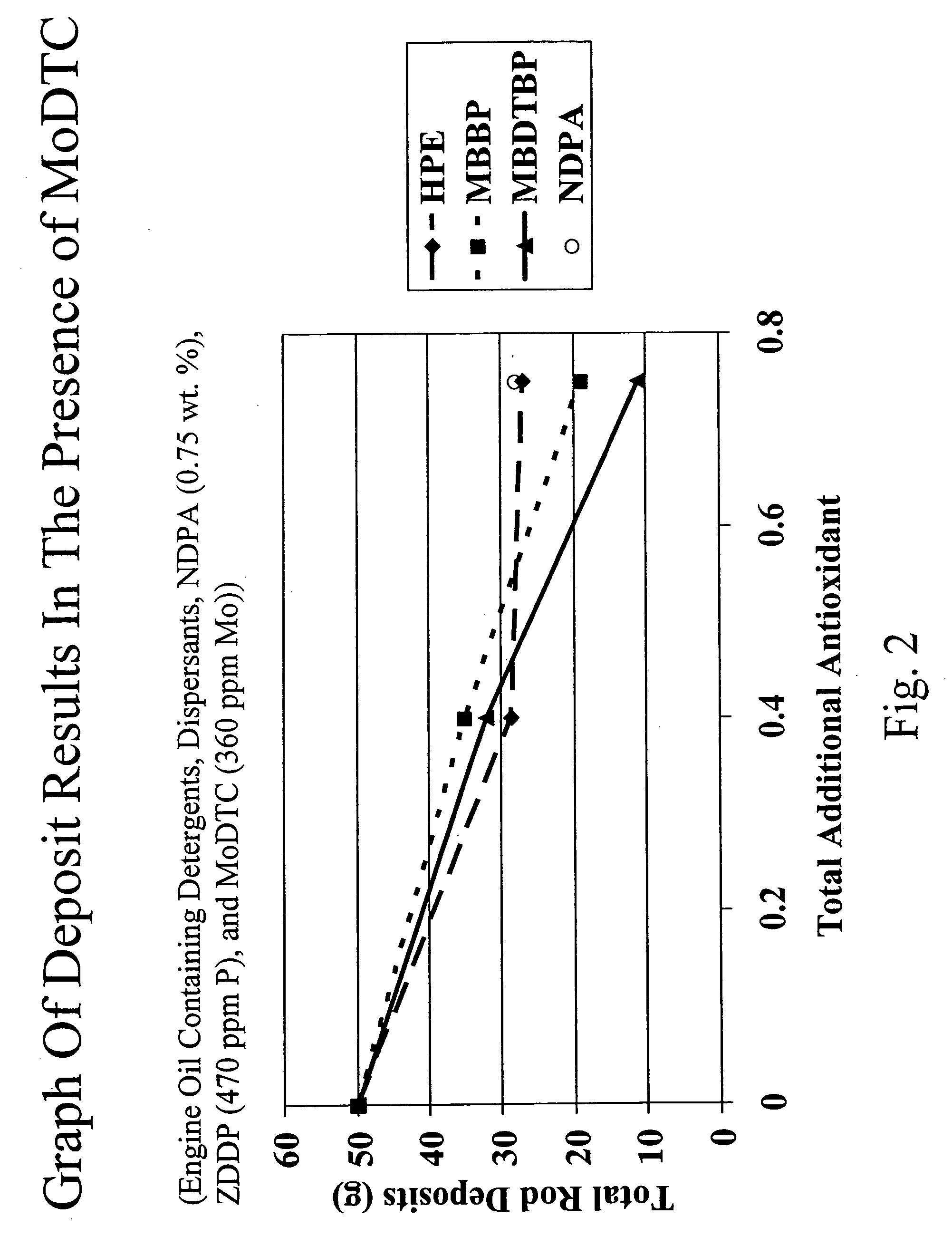

[0178] To this preblend was added the following components as indicated in Table 2 in preparation of a variety of engine oils. The finished engine oil contained the following (calculated): calcium 2400 ppm; phosphorus 470 ppm; zinc 520 ppm; and had a total base number of 7.5 mg KOH / g of oil.

[0179] The finished oils were tested in the TEOST MHT according to ASTM D7097. The certified medium deposit reference oil produced 60.6 mg of deposits in a calibration experiment. The certified high deposit reference oil produced 96.8 mg of deposits in a calibration experiment; these results represent a severe condition for the TEOS...

example b

Oil Thickening and Oxidation at Elevated Temperatures

[0183] A preblend was prepared by blending the following materials: [0184] 4.92 wt. % of an ashless dispersant concentrate; [0185] 1.85 wt. % of an overbased detergent concentrate containing calcium; [0186] 0.51 wt. % of a neutral detergent concentrate containing calcium; [0187]0.62 wt. % of a secondary zinc dialkyldithiophosphate; and [0188] 92.10 wt. % of a 150N Group II baseoil.

[0189] To this engine oil preblehd was added the components indicated in Table 3.

TABLE 3Components of Examples B.1-B.6.EngineOil Ex.PreblendHPENDPAZDDPMoNSOMBDTBPG2BOTotalNo.Example Type(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)B.1Comparative97.500.750.751.00100.00B.2Comparative97.500.750.750.290.71100.00B.3Comparative97.500.750.750.500.50100.00B.4Comparative97.500.750.751.00100.00B.5Comparative97.500.750.750.250.500.25100.00B.6Invention97.500.750.500.400.85100.00

MoN = A nitrogen-containing organomolybdenum compound containing 7.2 wt. % m...

example c

Oil Thickening and Oxidation

[0193] Oils A.2, A.3, A.7, A.9, A.11, A.13, A.15, A.16, and A.17 (Table 2) were evaluated in the bulk oil oxidation test described in Example B. In this study the oils were heated in a heating block at 150° C., while 10 liters / hour of dry oxygen was bubbled through the oil. Samples of the oxidized oils were removed at 24, 48, 72 and 96 hours. Kinematic viscosities of each sample were determined at 40° C. The percent viscosity increase of the oxidized oil versus the fresh oil was calculated. The percent viscosity increase results are shown in Table 5.

TABLE 5Percent viscosity increase of oils A.2, A.3, A.7, A.9, and A.11 in bulk oil oxidation test.TimeOil A.2Oil A.3Oil A.7Oil A.9Oil A.11Oil A.13Oil A.15Oil A.16Oil A.17(hrs)Compar.Compar.Compar.Compar.InventiveCompar.Compar.InventiveInventive24201001n / an / an / an / a485111215148522.10.701.6721933134292012073.01.90.73.39646175311295355262.82.01.5−0.3

n / a = not measured

[0194] These results show that Oil A.11 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com