Debris bagger

a bagger and debris technology, applied in the field of debris baggers, can solve the problems of reducing the ability of vacuum shredders, difficult to move trash cans or frames at the same time, and not as portable as vacuum shredders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

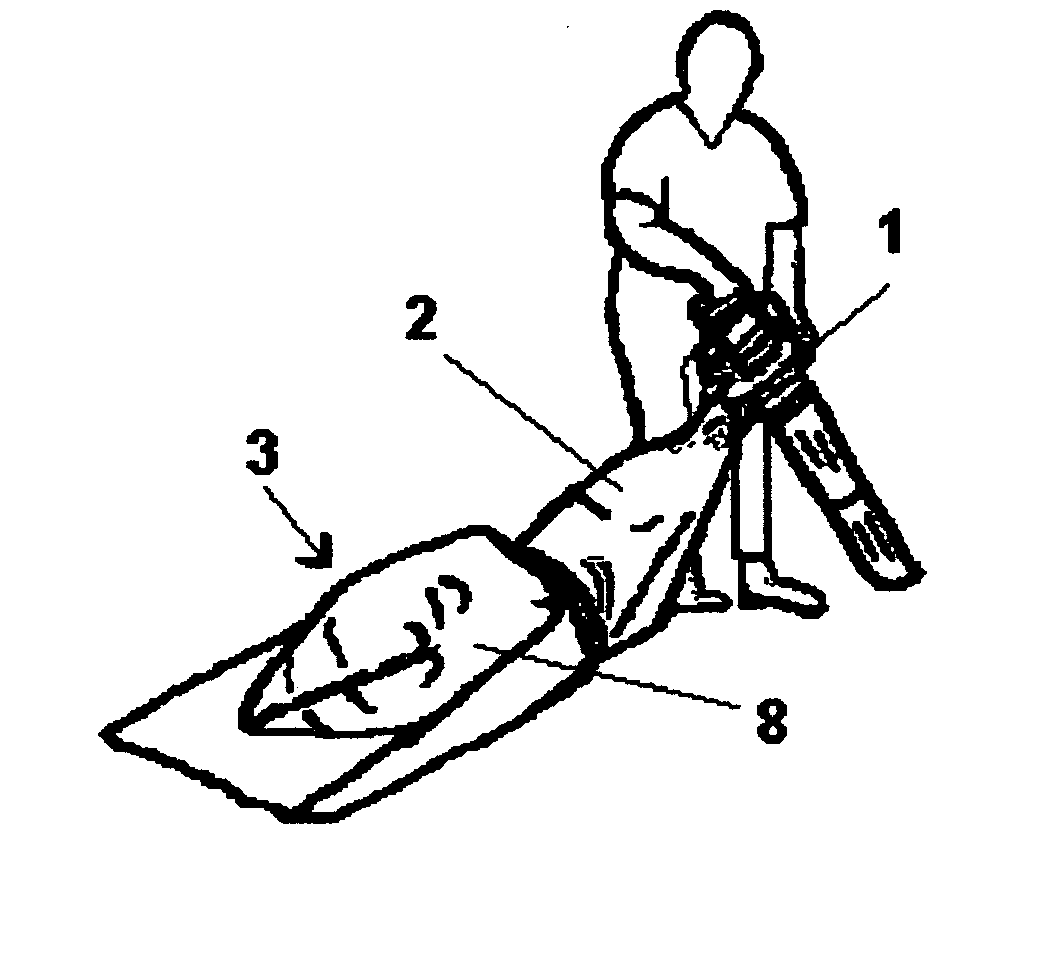

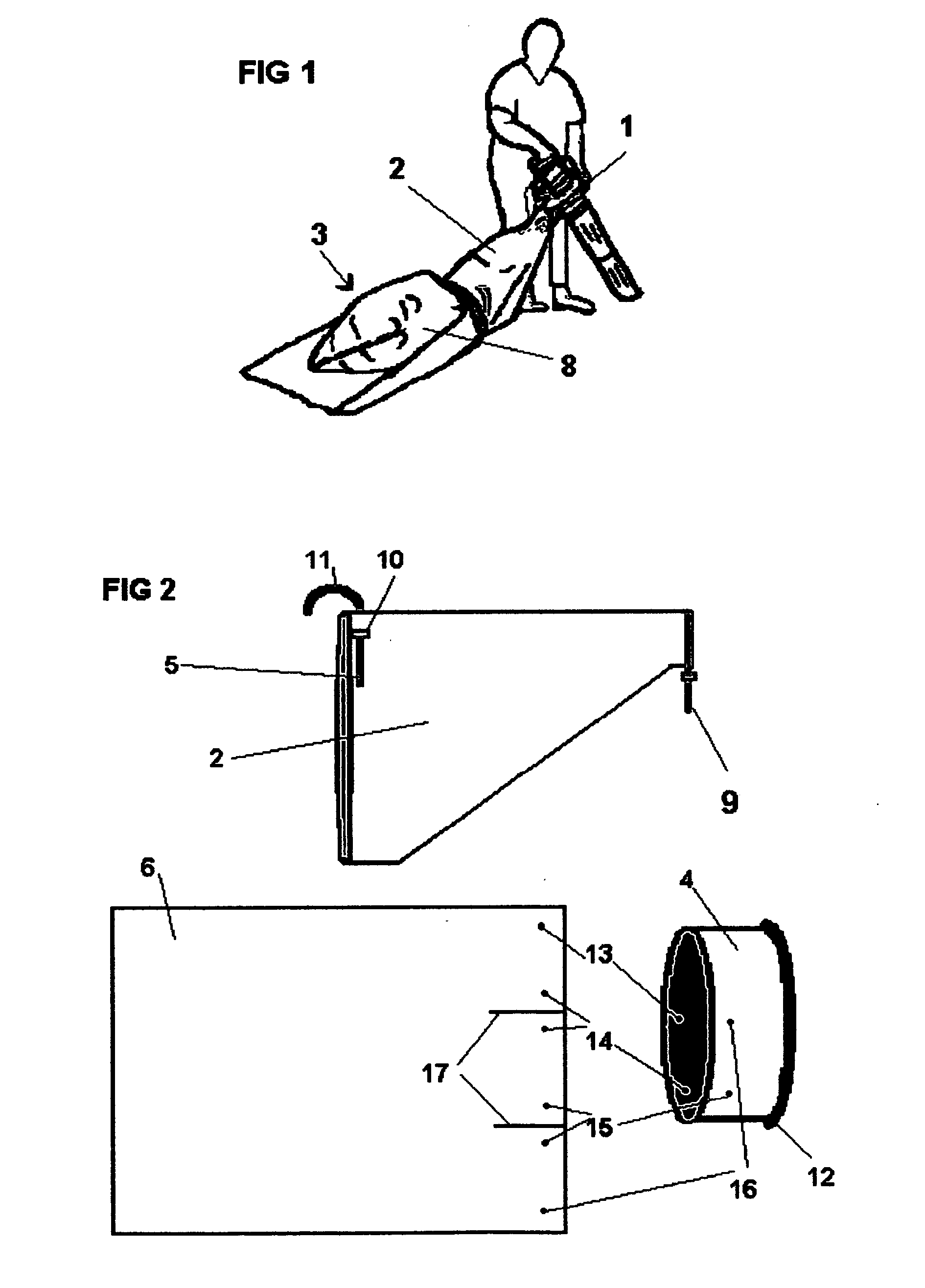

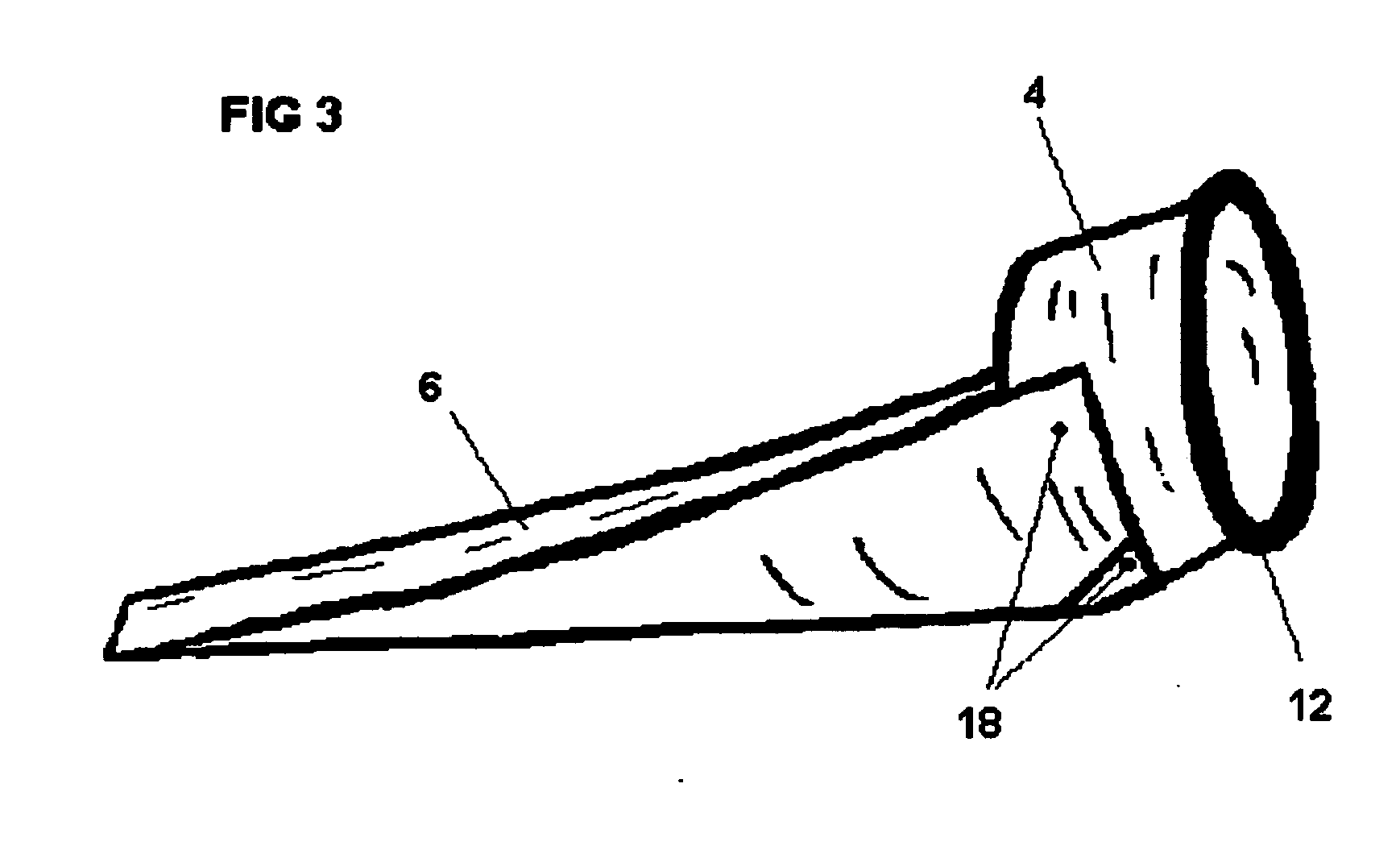

[0022] The present invention is pulled behind the operator by the tapered filter bag attached to the tubular adapter ring that comes with the bagger. This tubular adapter ring is made of a suitable size, stiffness and material to hold the top of a common trash disposal bag in an open position. The top end of this adapter ring has a ridge on the outer circumference. The purpose of this adapter ring is to attach the open end of the filter bag to the open end of the disposal bag. A disposal bag is installed into the top ridge end of the adapter ring and folded over the ridge. This is done just as if the adapter ring was the top of a trashcan. The adapter ring is installed into the outlet end of the filter bag and held in place with a clamp ring. The clamp ring is made of stiff material of appropriate length and width to clamp the bags onto the adapter ring. The disposal bag is held in place by this same clamp ring that is made into the edge on the large end of the filter bag. The clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com