Drip irrigation system

a drip irrigation and drip technology, applied in the direction of applications, rigid pipes, flexible pipes, etc., can solve the problems of large water consumption, large pressure loss along the branching tubes of drip emitters, and substantial investment costs and power consumption in operation, so as to achieve low investment costs, simple assembly method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

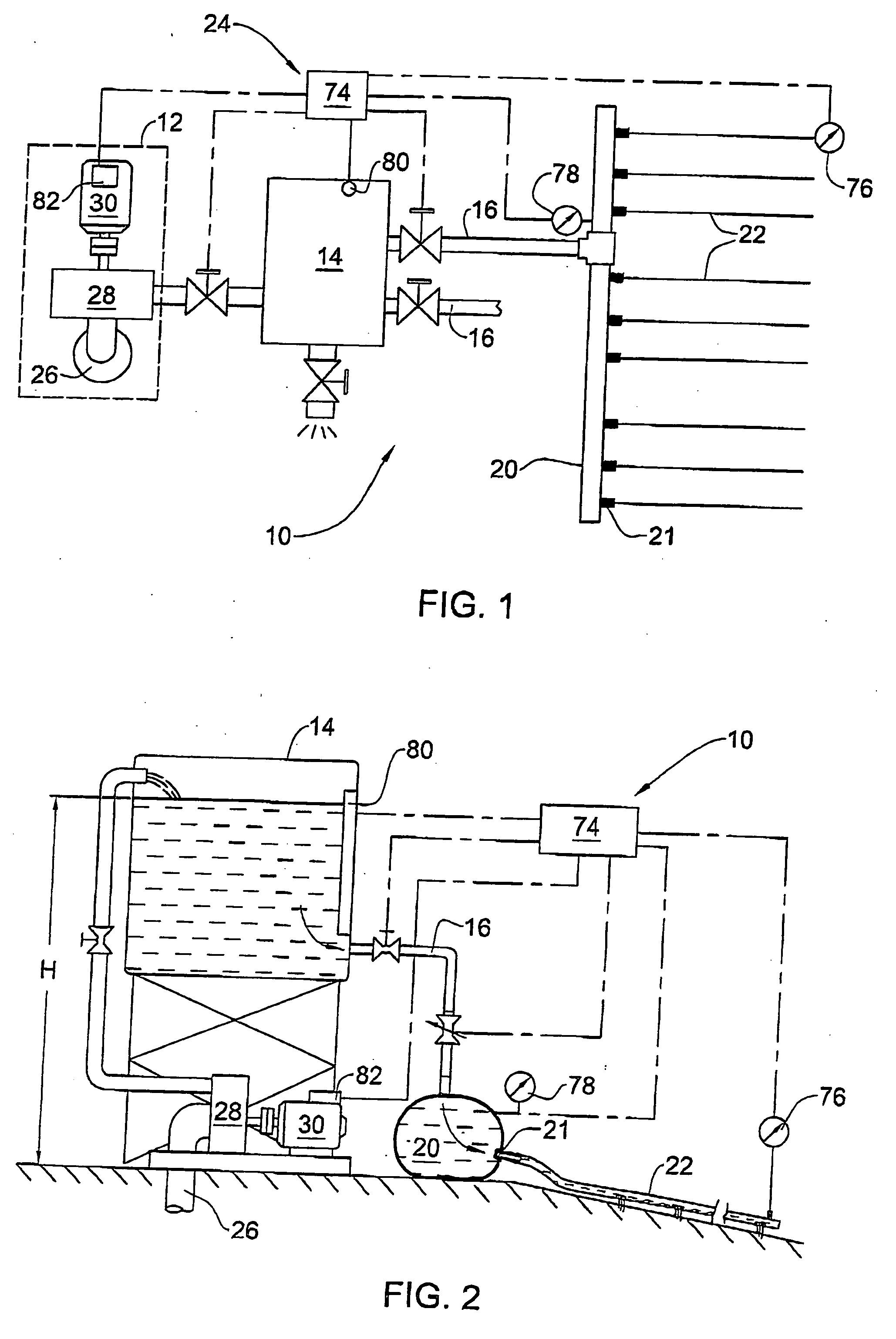

[0046] With reference to FIGS. 1 and 2, there is shown a low-pressure drip irrigation system 10, comprising a source of irrigation water 12, gravitation filter tank 14, outlet pipes 16, distribution pipes 20, connectors 21, branch tubes 22, and control system 24.

[0047] The source of irrigation water 12 in FIG. 1 is an artesian well 26 with a pump 28 and an electric drive 30, but may be any other suitable source. It is connected to the filter tank 14 which will be described in detail below. The filter tank 14 is connected to the pipes 20 by means of the outlet pipes 16.

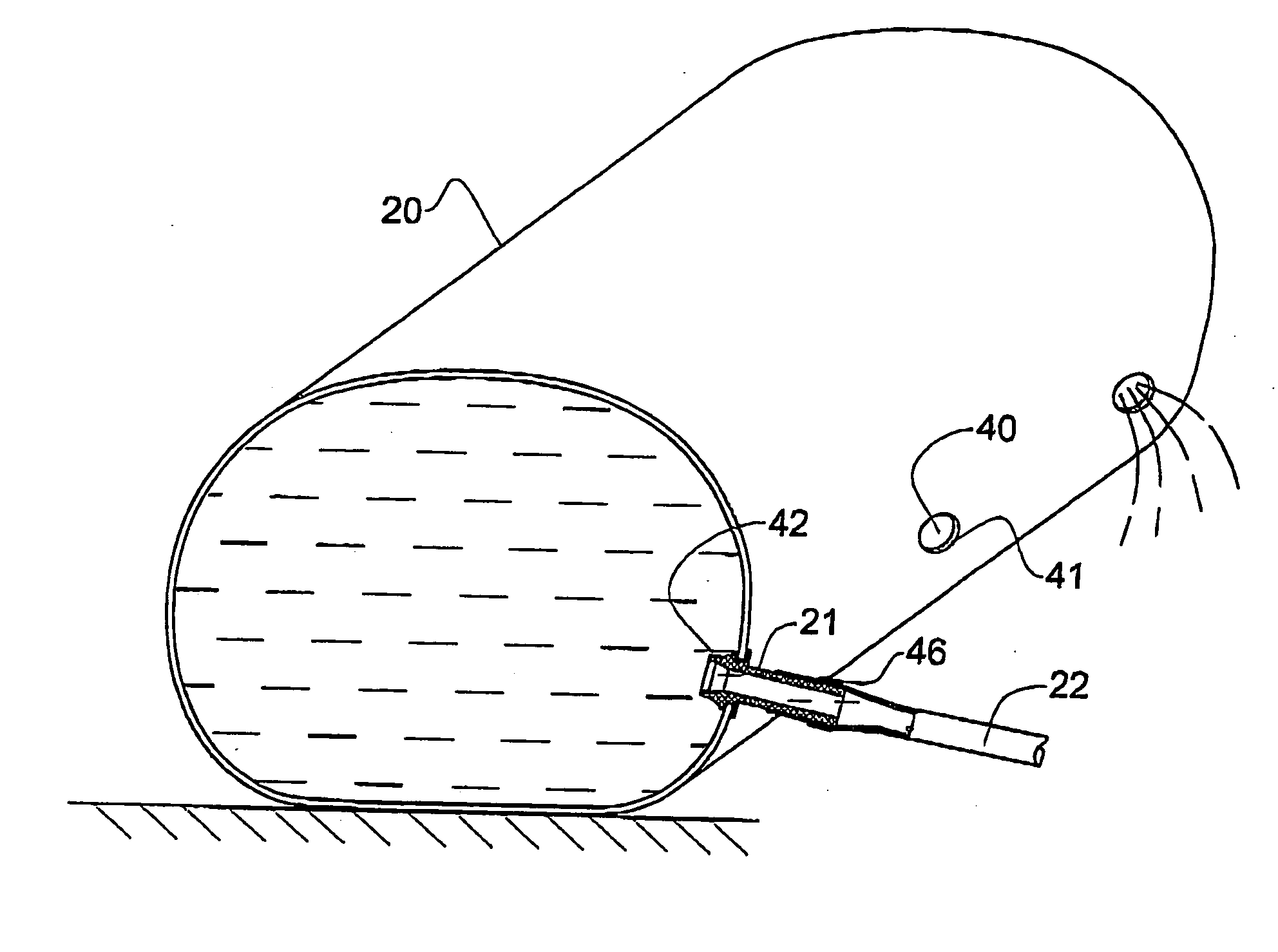

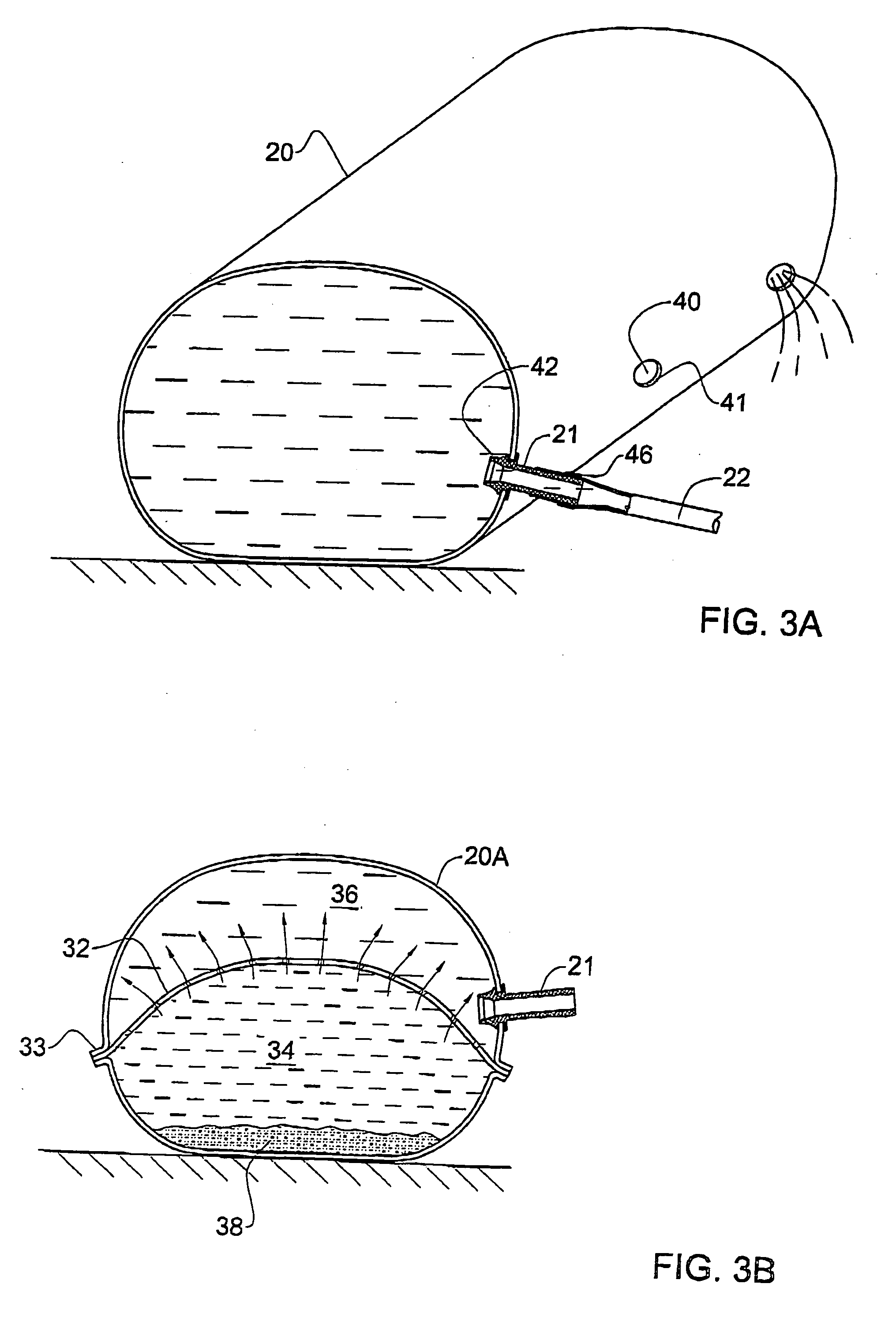

[0048] With reference also to FIG. 3A, the distribution pipe 20 has a plurality of holes 40 with edges 41 which are tightly fixed to base parts 42 of the connectors 21. The pipes 20 are used in generally horizontal state, while the branch tubes 22 may be slightly inclined, so as to maintain approximately uniform head in all drip emitters.

[0049] The distribution pipe 20 is made of thin-walled plastic collapsible slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com