Shipping and display carton

a display box and packaging technology, applied in the field of stackable tray packages, can solve the problems of trays that cannot easily survive undamaged, manufacturers are required to use substantial extra labor and shipping materials, and trays require significant manual labor, so as to prevent vertical stack failure, improve design, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] While the invention is described below with respect to a preferred embodiment, other embodiments are possible. The concepts disclosed herein apply equally to other stackable product trays, including any container with substantially vertical sides and an open top. The invention is described below with reference to the accompanying figures.

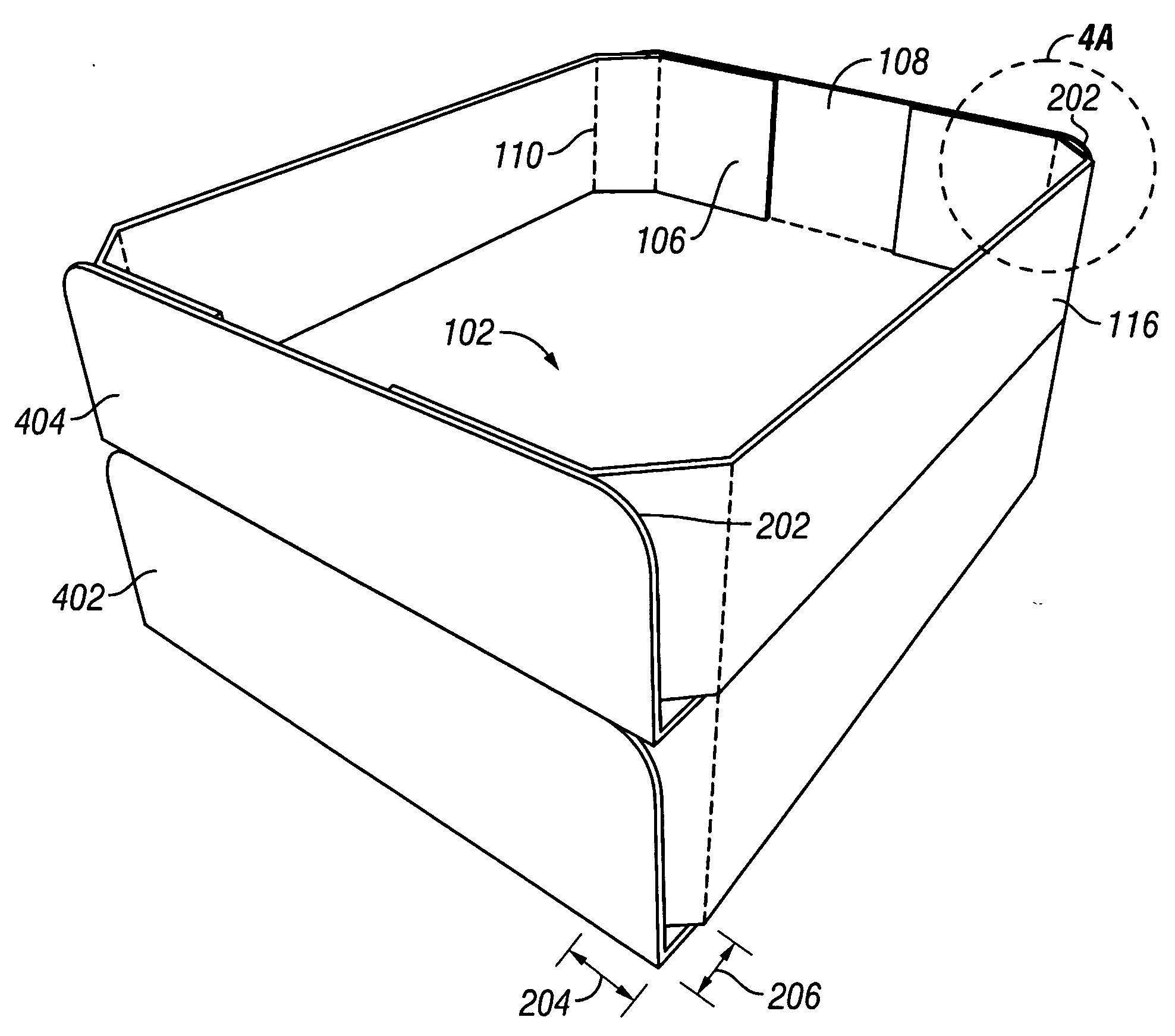

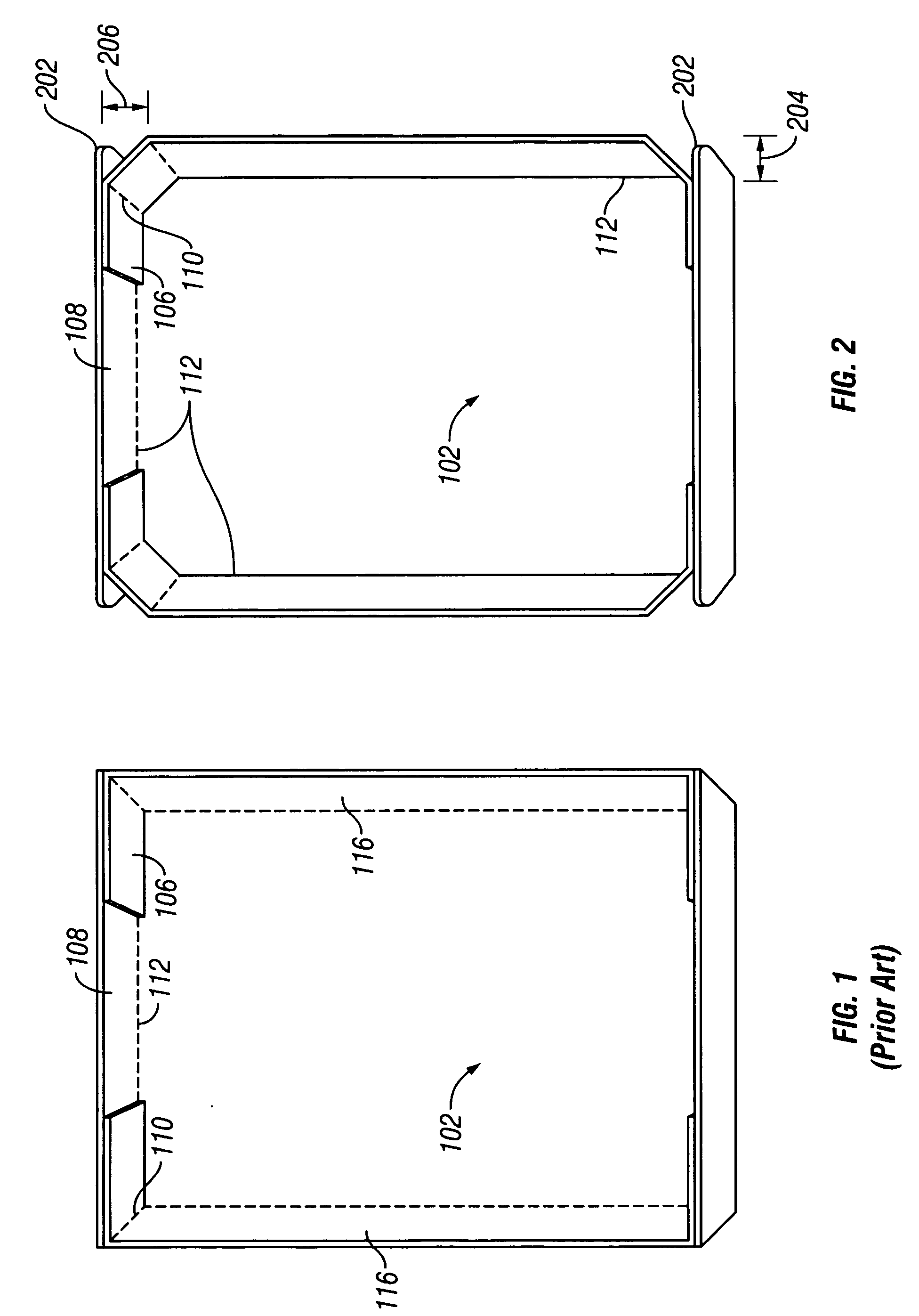

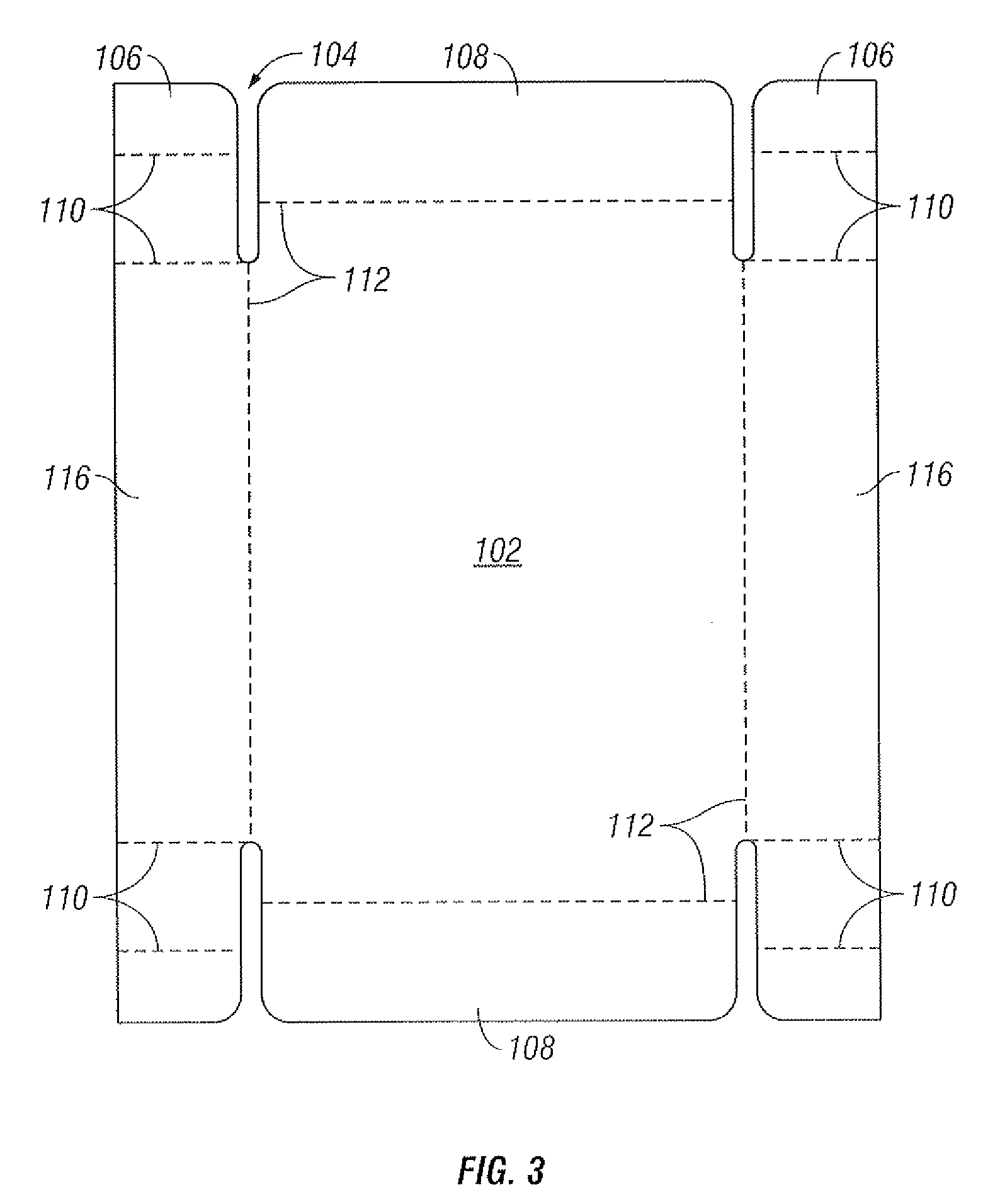

[0043]FIG. 2 shows an overhead view of a product tray according to a preferred embodiment of the invention. This product tray has substantially the same volume as a traditional prior art tray such as a prior art tray shown in FIG. 1. With reference to FIG. 2, the long sides 116 or sidewalls, and short sides 108 or endwalls, are both folded at ninety degrees to form a generally rectangular tray. The long sides 116 and short sides 108 are folded along side crease lines 112 made by a forming machine. In one embodiment, side crease lines 112 are fully or partially perforated, but may be just creased. Folding the sides 108, 116 at an angle less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com