Image forming method and apparatus with improved conversion capability of amount of toner adhesion

a technology of toner adhesion and conversion capability, which is applied in the direction of electrographic process apparatus, instruments, printing, etc., can solve the problem of difficulty in conventional detection methods to accurately detect the amount of adhesion, and achieve the effect of reducing or eliminating many

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0079] According to the invention, there provided is a method of converting the amount of adhesion, comprising the steps of

[0080] forming a plurality of gradation powder patterns,

[0081] detecting optically each of the plurality of gradation powder patterns,

[0082] computing a normalization value, obtaining a diffuse reflection output conversion factor, and

[0083] subjecting the relation between the diffuse reflection output conversion factor and the amount of adhesion to a polynomial approximation.

[0084] The abovementioned step of forming a plurality of gradation powder patterns includes forming the patterns continuously on the surface to be detected, in which the plurality of gradation powder patterns each have different amount of adhesion;

[0085] the step of detecting optically each of the plurality of gradation powder patterns includes detecting with a sensor configured to simultaneously detect regular reflection light and diffuse reflection light to obtain a regular reflection...

second embodiment

[0091] According to the invention, there provided is a method of converting the amount of adhesion, comprising the steps of forming a plurality of gradation toner patterns, detecting optically each of the plurality of gradation toner patterns, computing a normalization value, obtaining a diffuse reflection output conversion factor, and subjecting the relation between the diffuse reflection output conversion factor and the amount of adhesion to a polynomial approximation.

[0092] The abovementioned step of forming a plurality of gradation toner patterns includes forming the patterns continuously on the surface to be detected, in which the plurality of gradation toner patterns each have different amount of adhesion; the step of detecting optically each of the plurality of gradation toner patterns includes detecting with a sensor configured to simultaneously detect regular reflection light and diffuse reflection light to obtain a regular reflection output voltage and a diffuse reflection...

third embodiment

[0101] an image forming apparatus is provided being capable of performing at least anyone of the methods of converting the amount of adhesion, described above.

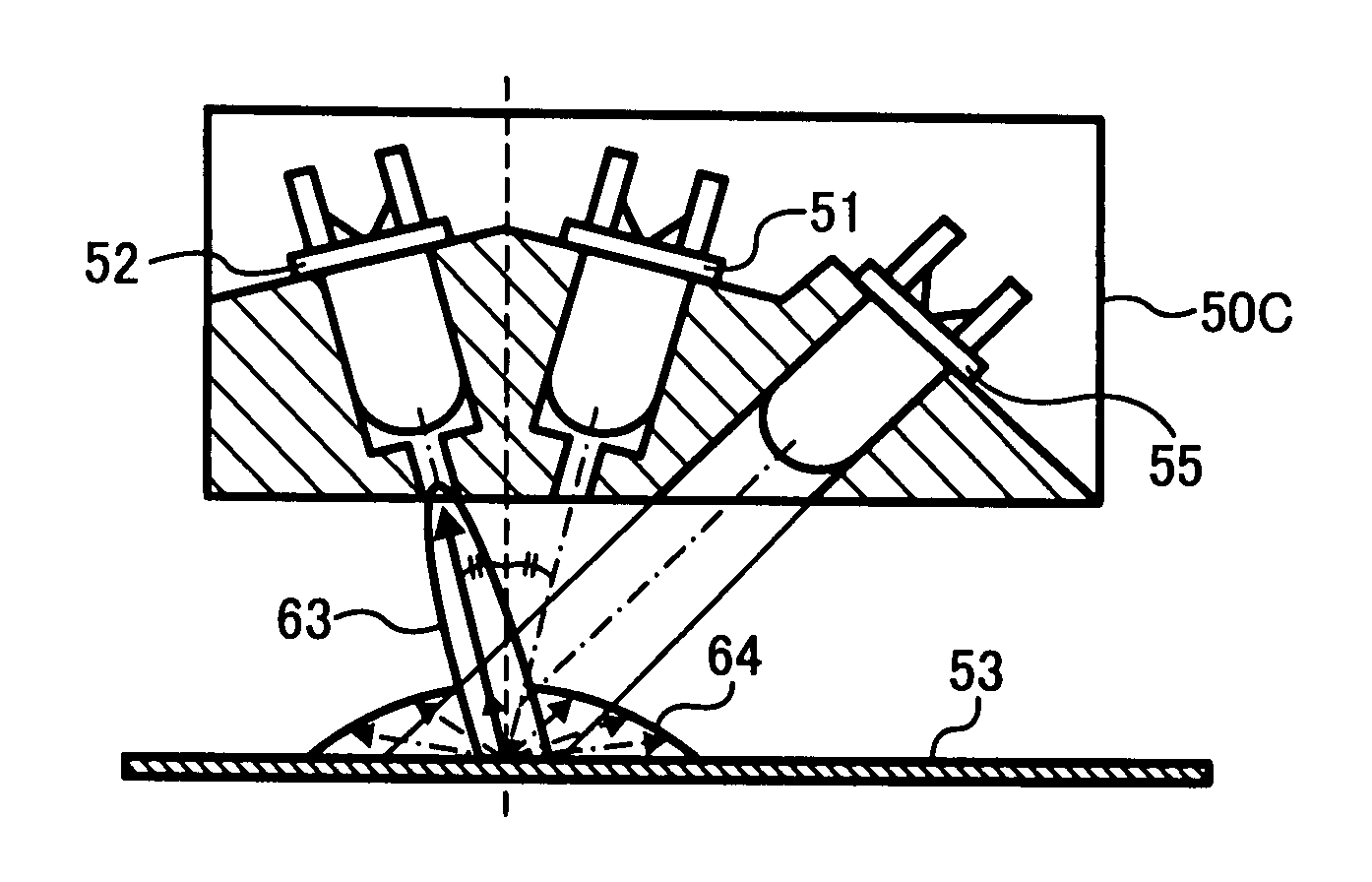

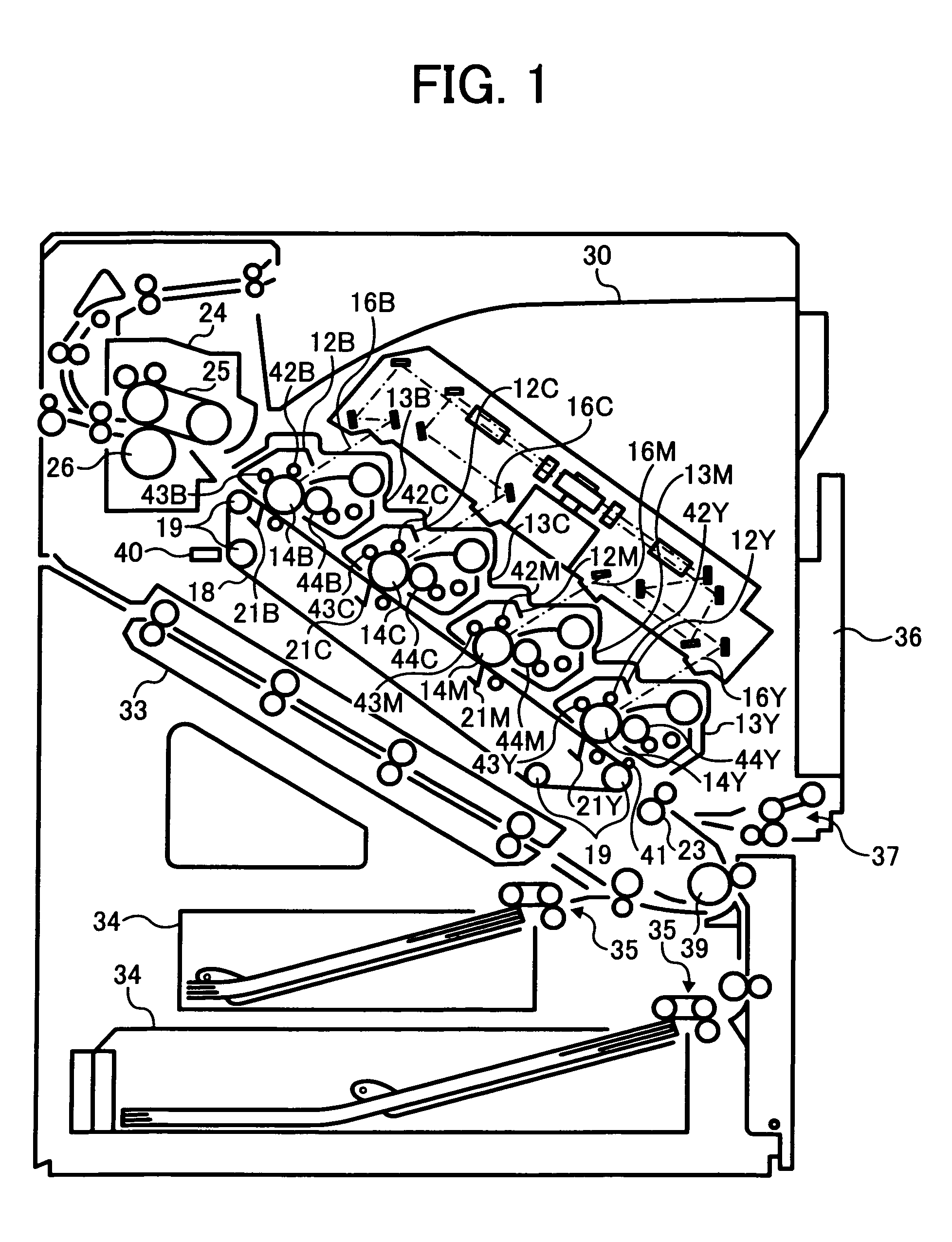

[0102] Having described the present disclosure in general, several preferred embodiments of the method of converting the amount of toner adhesion will be described herein below according to the present invention in reference to FIGS. 1 through 35.

[0103] In the first place, before detailing the configuration and the function in this embodiment, the circumstances for realizing the present invention will be described.

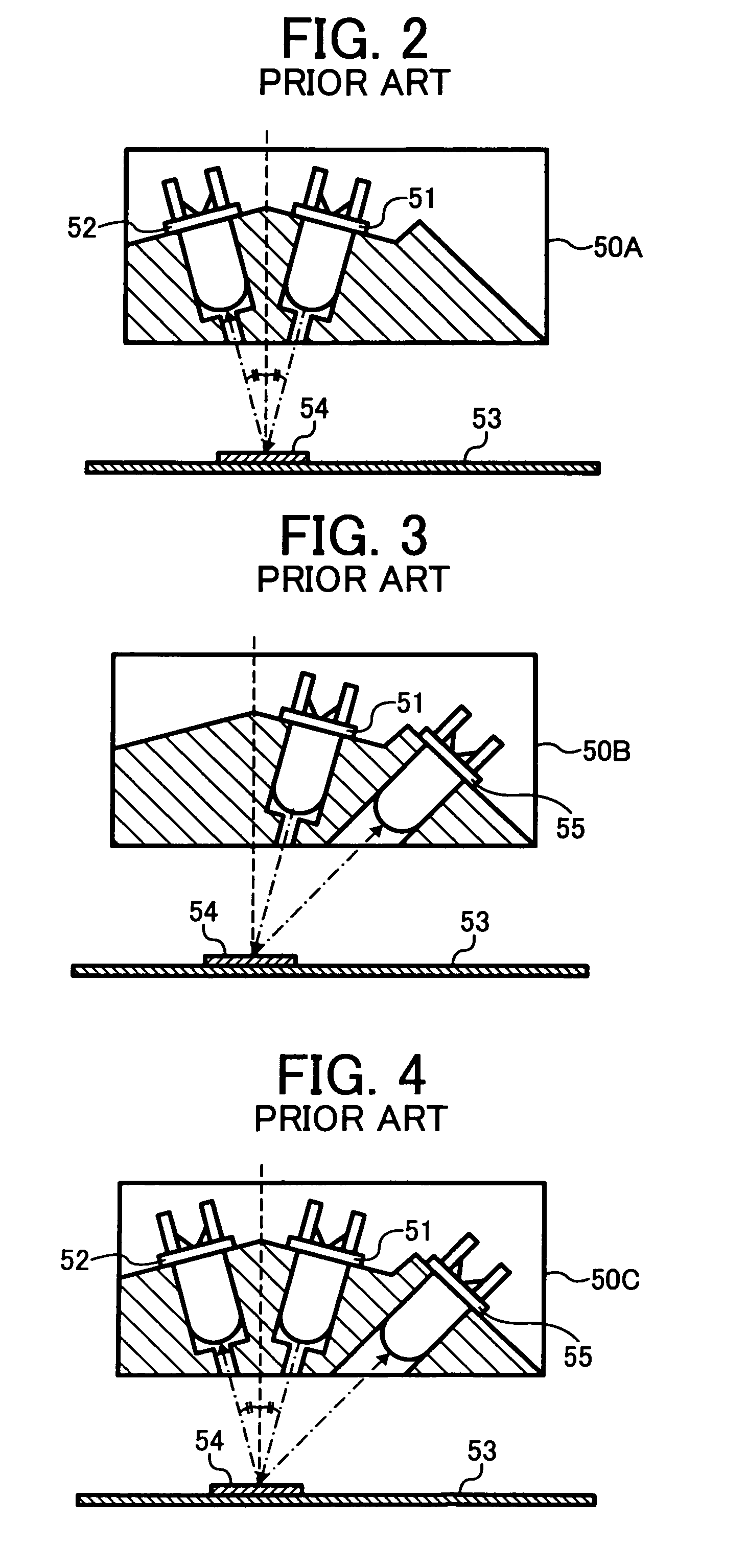

[Examination on Configuration and Function of Optical Detection Means]

[0104] When it is considered which type of optical sensors is used for detecting the density gradation pattern on the transfer belt serving as the target face for detection,

[0105] (A) in a first type of the sensor configured to detect only the regular reflection light, there is a drawback in that the detection up to the high adhesion range is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com