Methods and apparatus for optimizing environmental humidity

a technology of environmental humidity and optimizing methods, applied in lighting and heating apparatus, instruments, heating types, etc., can solve the problems of less than optimal or inaccurate testing, damage to chamber and dut components, and excessive moisture condensation, etc., to increase and/or decrease the humidity of the chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

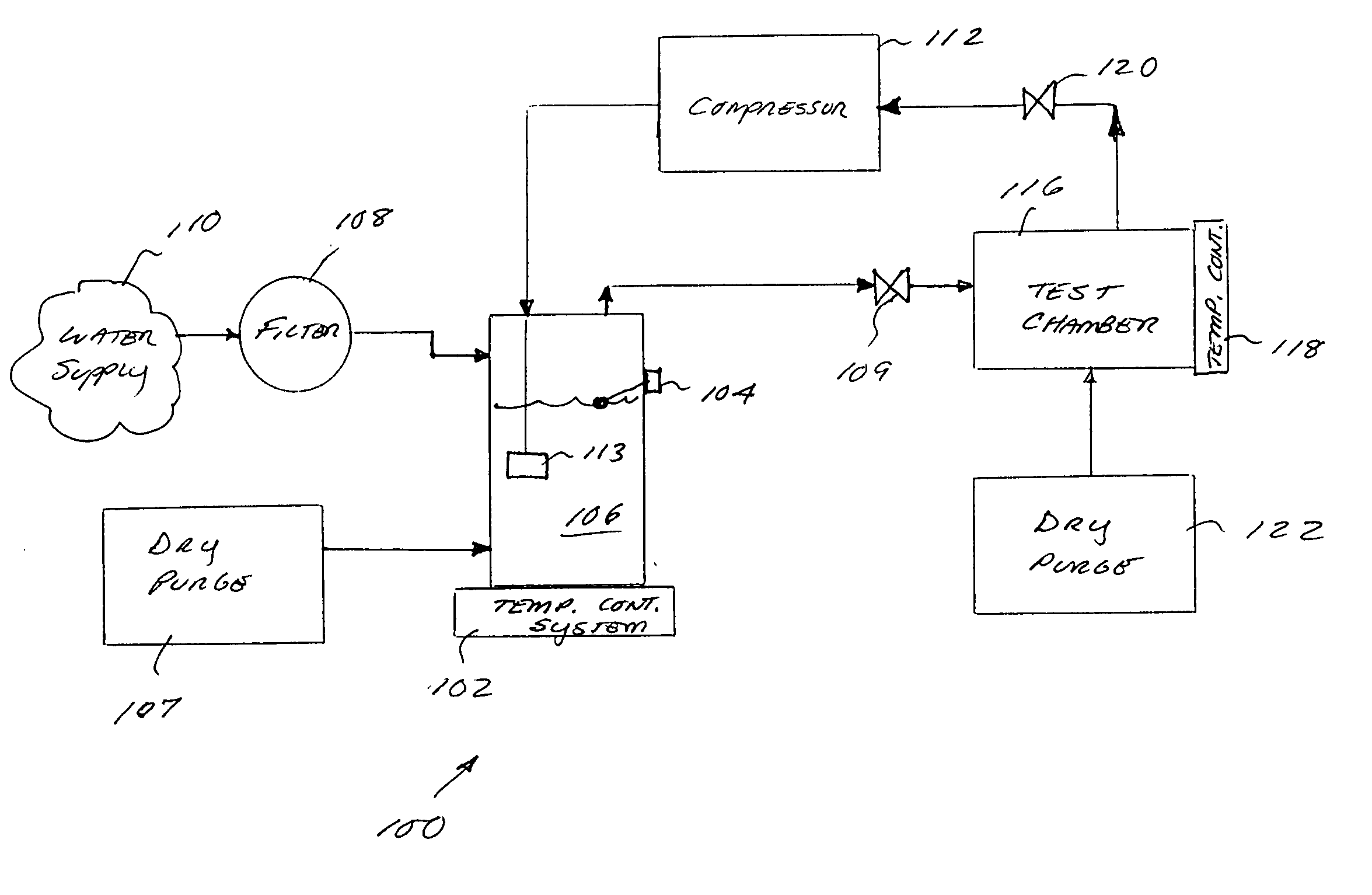

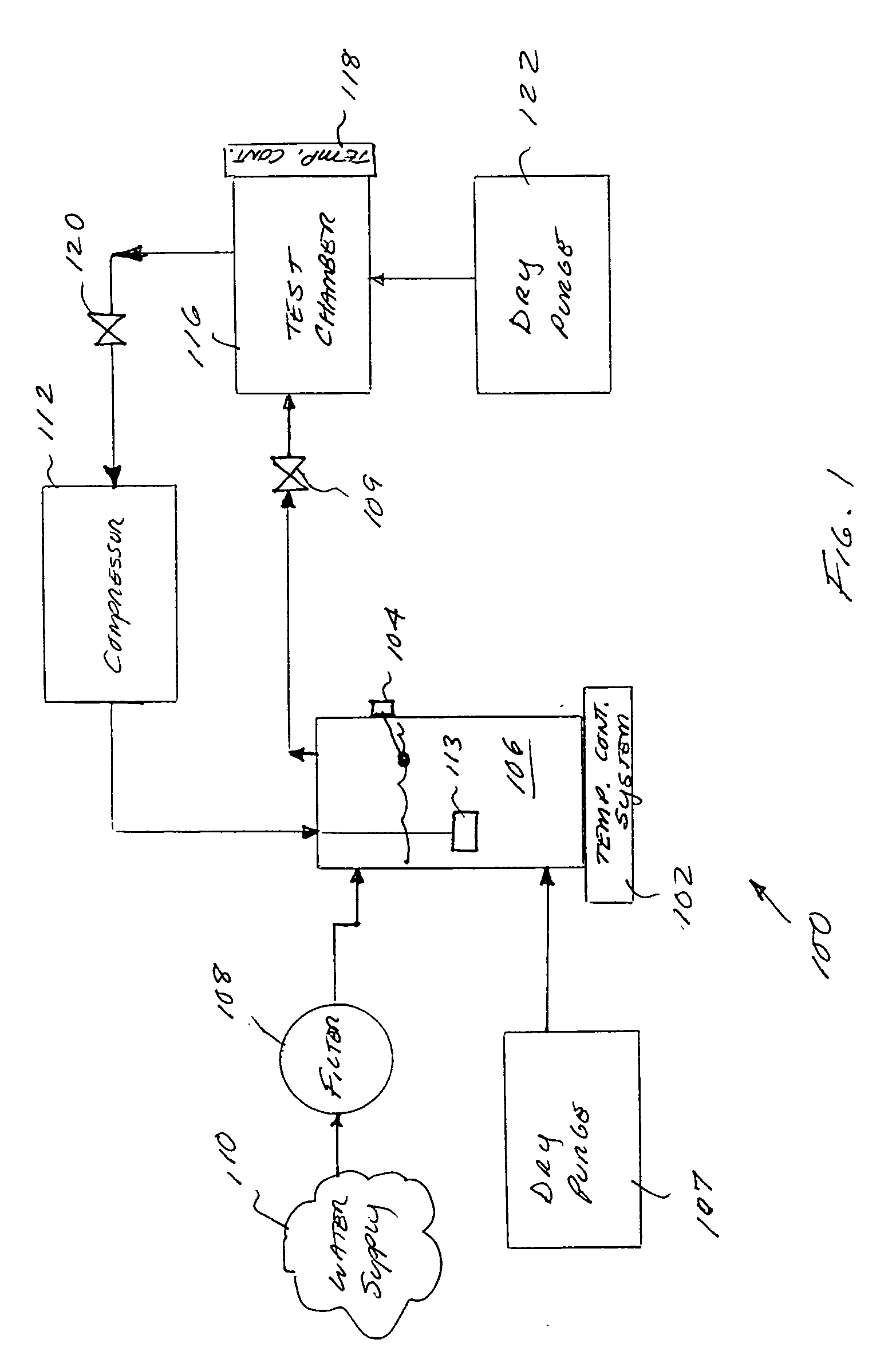

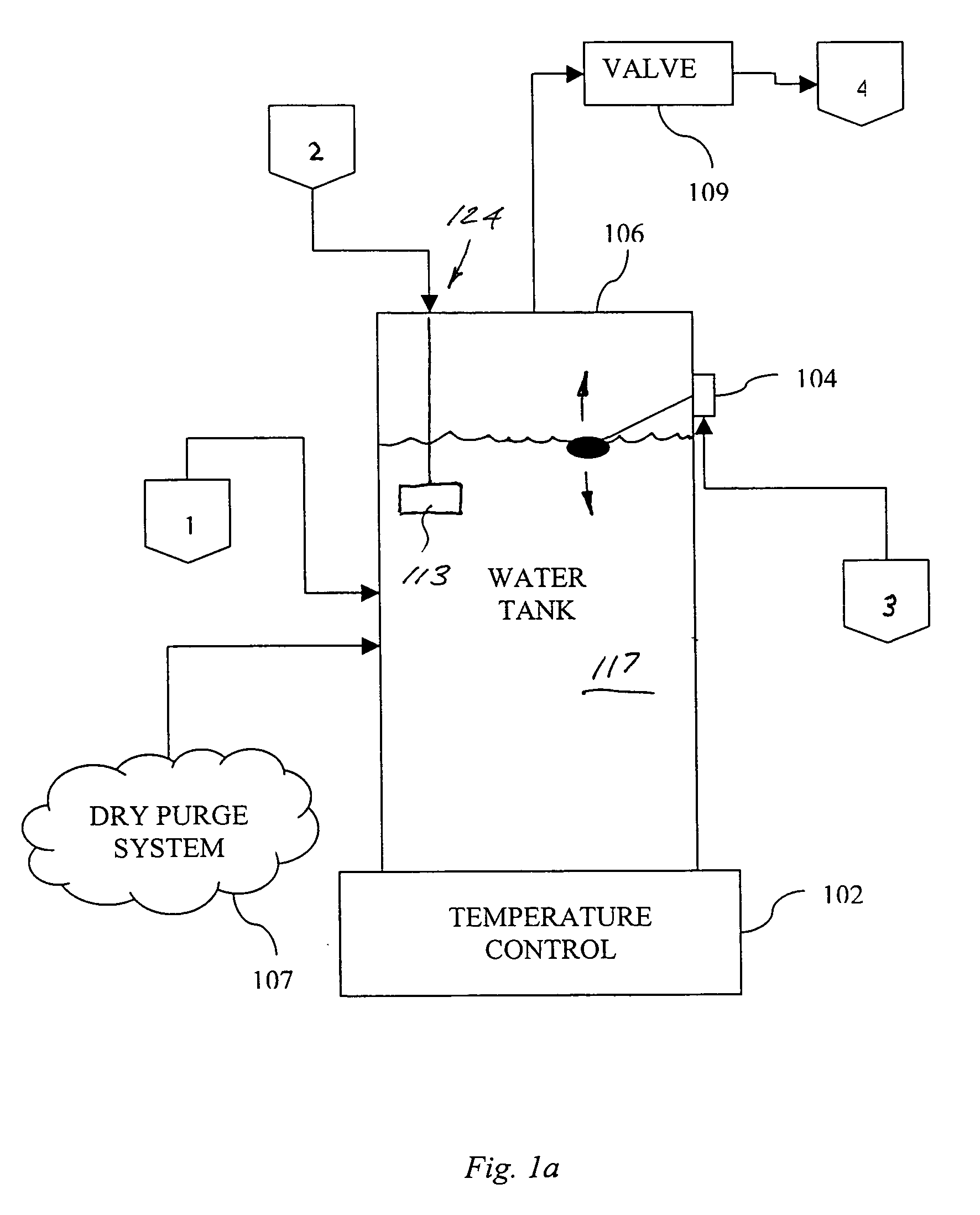

[0035] Reference is now made to the drawings wherein like numerals refer to like parts throughout.

[0036] As used herein, the term “device under test” or “DUT” refers generally to any component, material, assembly, or device which is being tested, evaluated, or conditioned. DUT's can include, without limitation, electronic or mechanical devices or assemblies, integrated circuits, semiconductors, diodes, material specimens or samples, or crystals.

[0037] As used herein, the term “humidity” refers generally to the concentration of one material in another. In the exemplary instance, humidity refers to the relative water (vapor) content within air; however, the term is also meant to encompass water content in other gases, and even the content of non-water liquids carried within air or other types of gases.

[0038] It is noted that while the following description is cast primarily in terms of an improved apparatus and method for use in controlling temperature and humidity within an enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com