Bottle and cap closure apparatus with torque feature

a closure apparatus and bottle neck technology, applied in the field of bottle neck closure apparatus, can solve the problems of bottle cap loosening bottle cap slipping, etc., and achieve the effect of preventing unintended backing off of the bottle cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

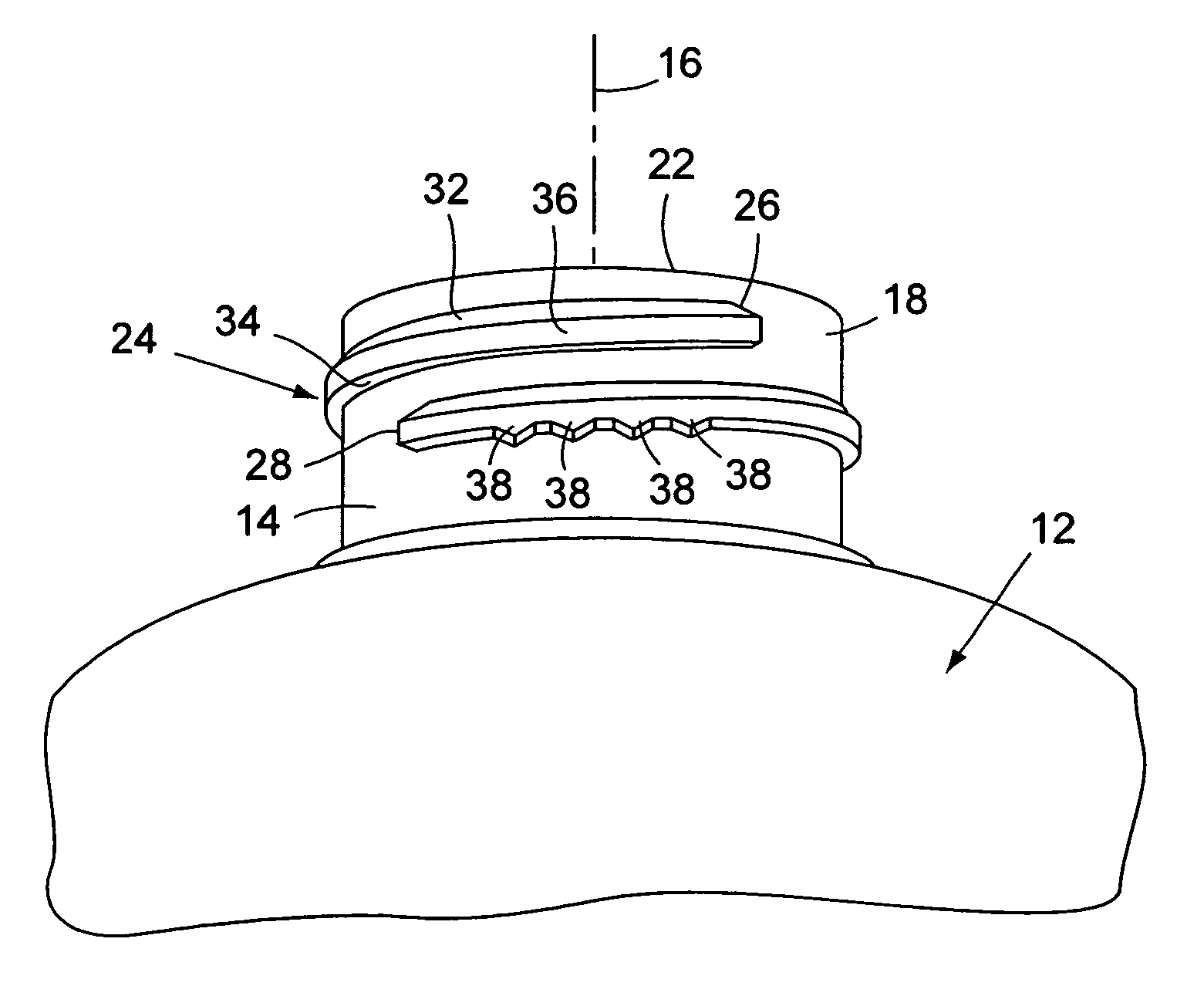

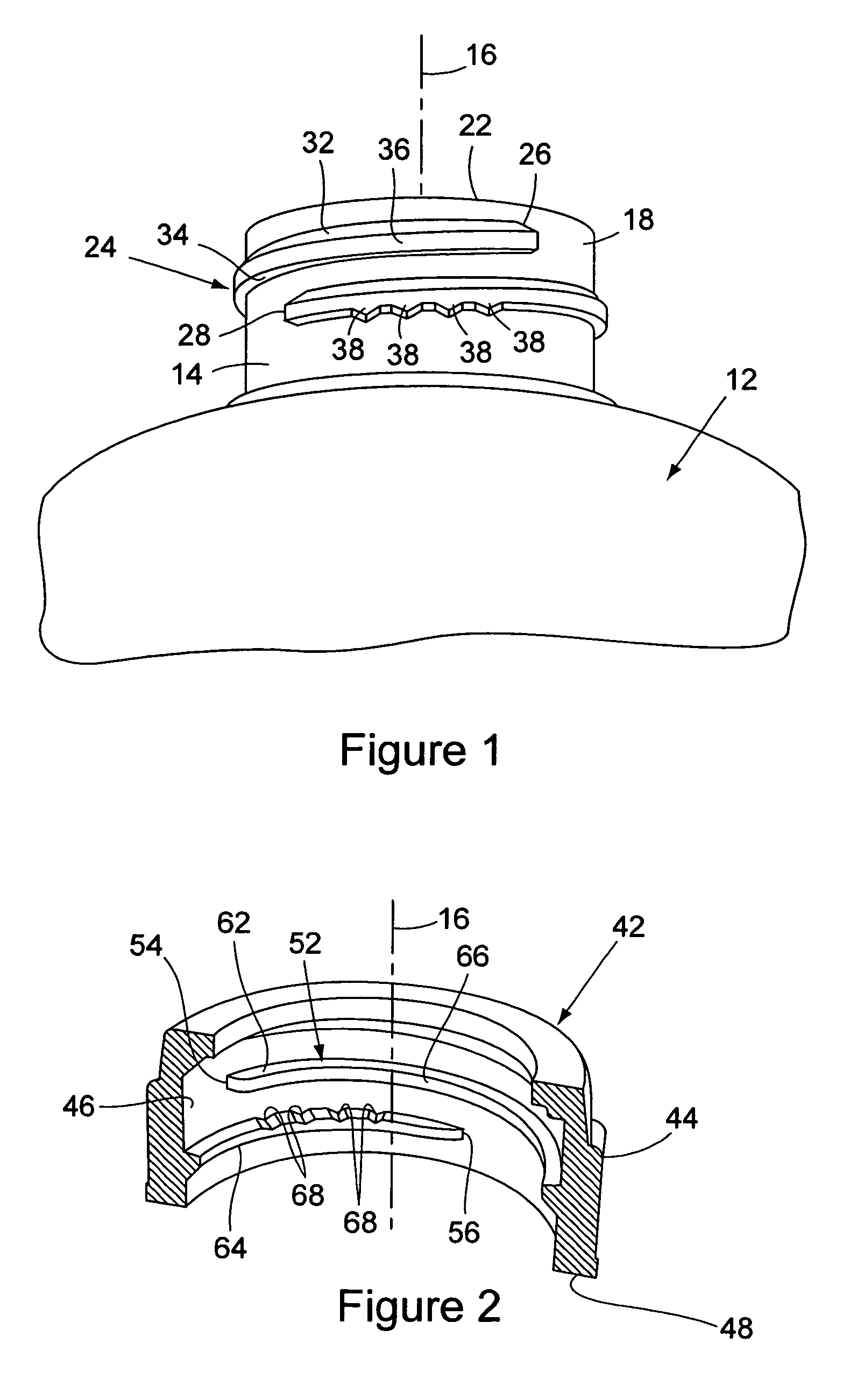

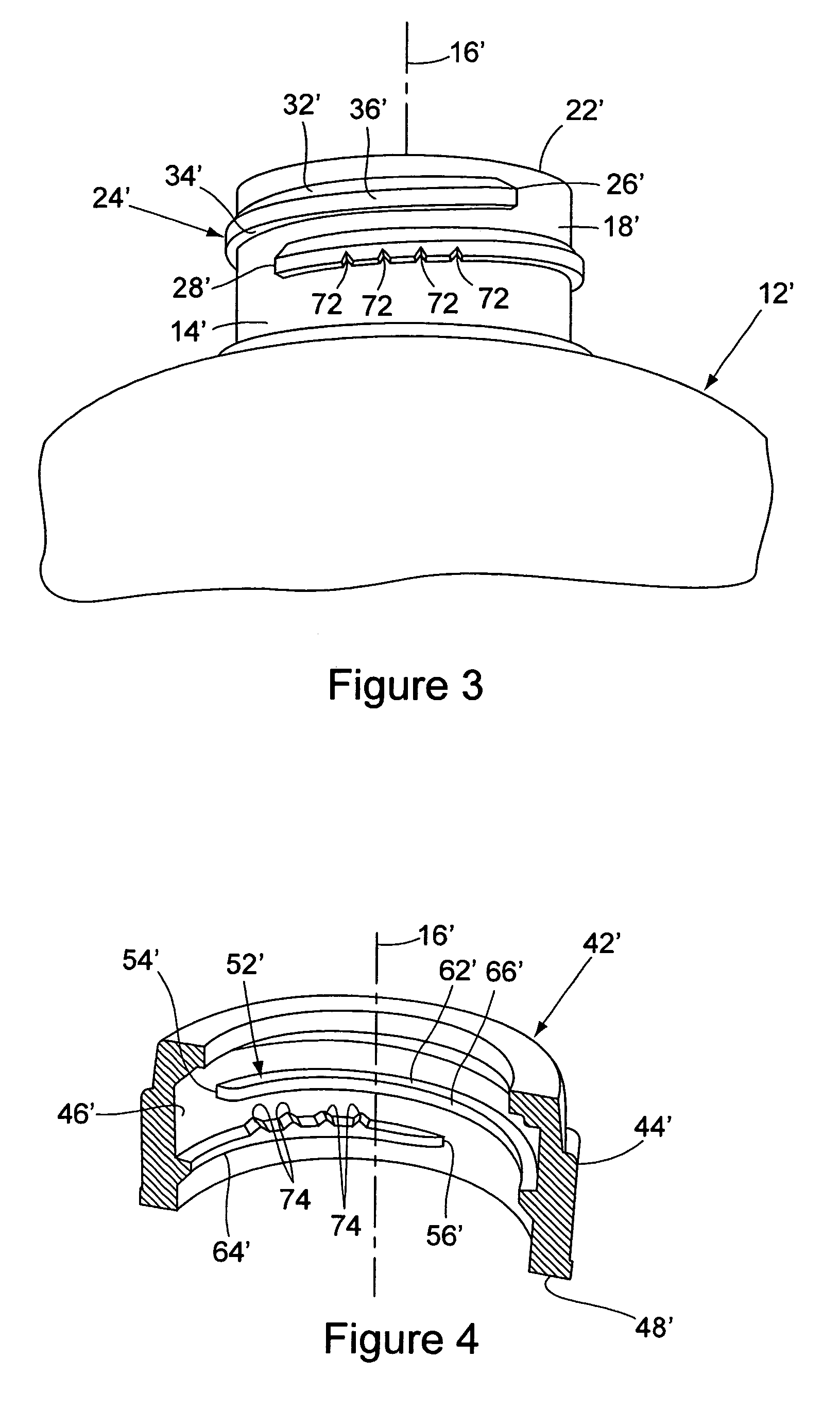

[0020] Each of the embodiments of the bottle neck closure apparatus to be described could simply be used to close the opening of a bottle, or could be used as an attachment for another component to the bottle, for example a hand operated trigger sprayer. In each of the embodiments to be described the component parts of the embodiments are constructed of materials typically used in the construction of bottle and cap closures, for example plastic material. A first embodiment of the bottle and cap closure apparatus of the invention is shown in FIGS. 1 and 2.

[0021]FIG. 1 shows an upper portion of a bottle 12 having a cylindrical bottle neck 14. The bottle neck 14 surrounds an opening to an interior volume of the bottle. The bottle neck and bottle opening have a center axis 16 that defines mutually perpendicular axial and radial directions relative to the bottle 12 and the bottle neck 14. The bottle neck 14 has a cylindrical exterior surface 18 that extends upwardly from the bottle 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com