Scaffold frame section with integral guard rail post

a guard rail and scaffold frame technology, applied in the direction of scaffold accessories, constructions, building aids, etc., can solve the problems of unsafe elevated positions of platforms, scaffold assemblies with improperly and unsafe positions, and significant falling hazards for workers standing on platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

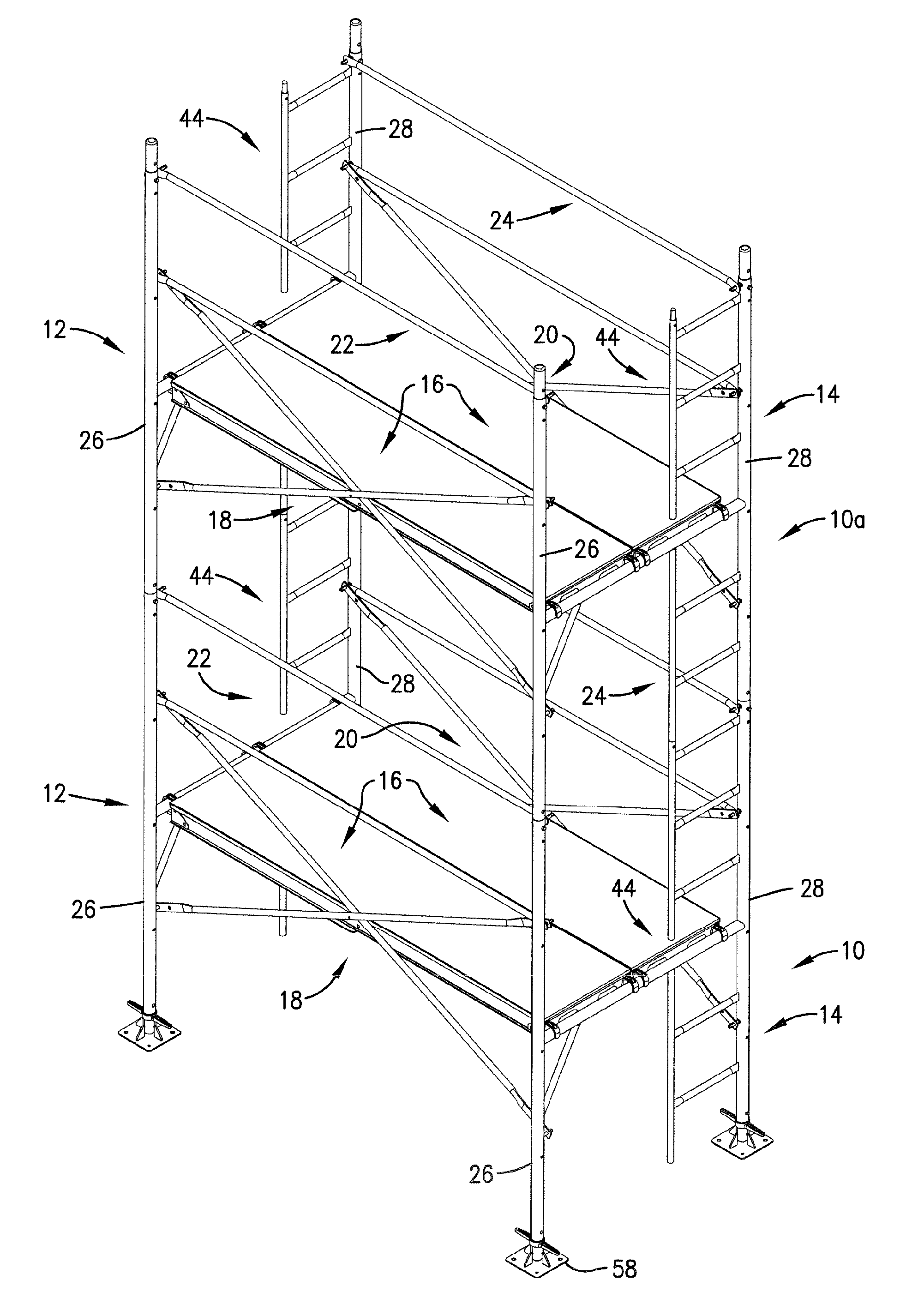

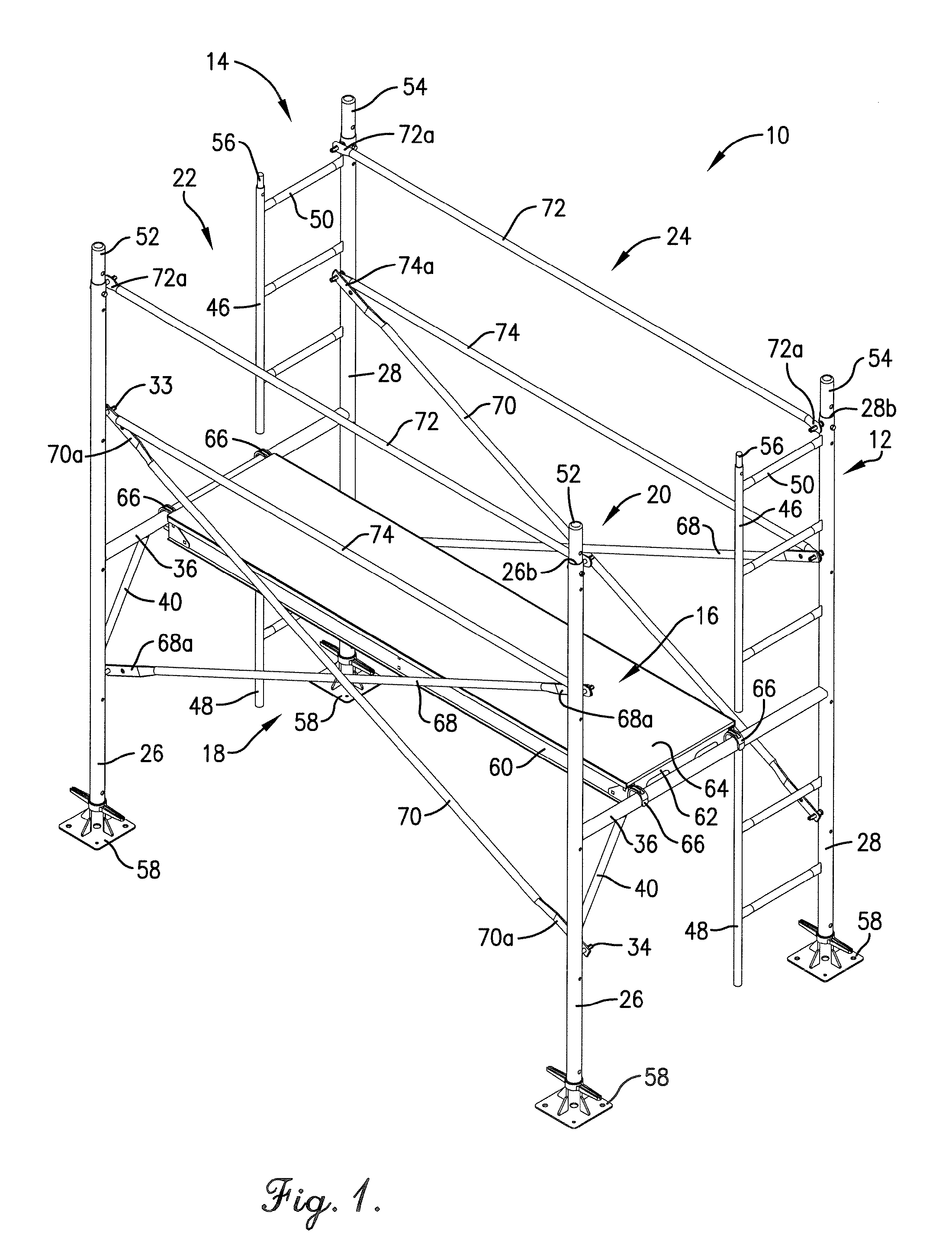

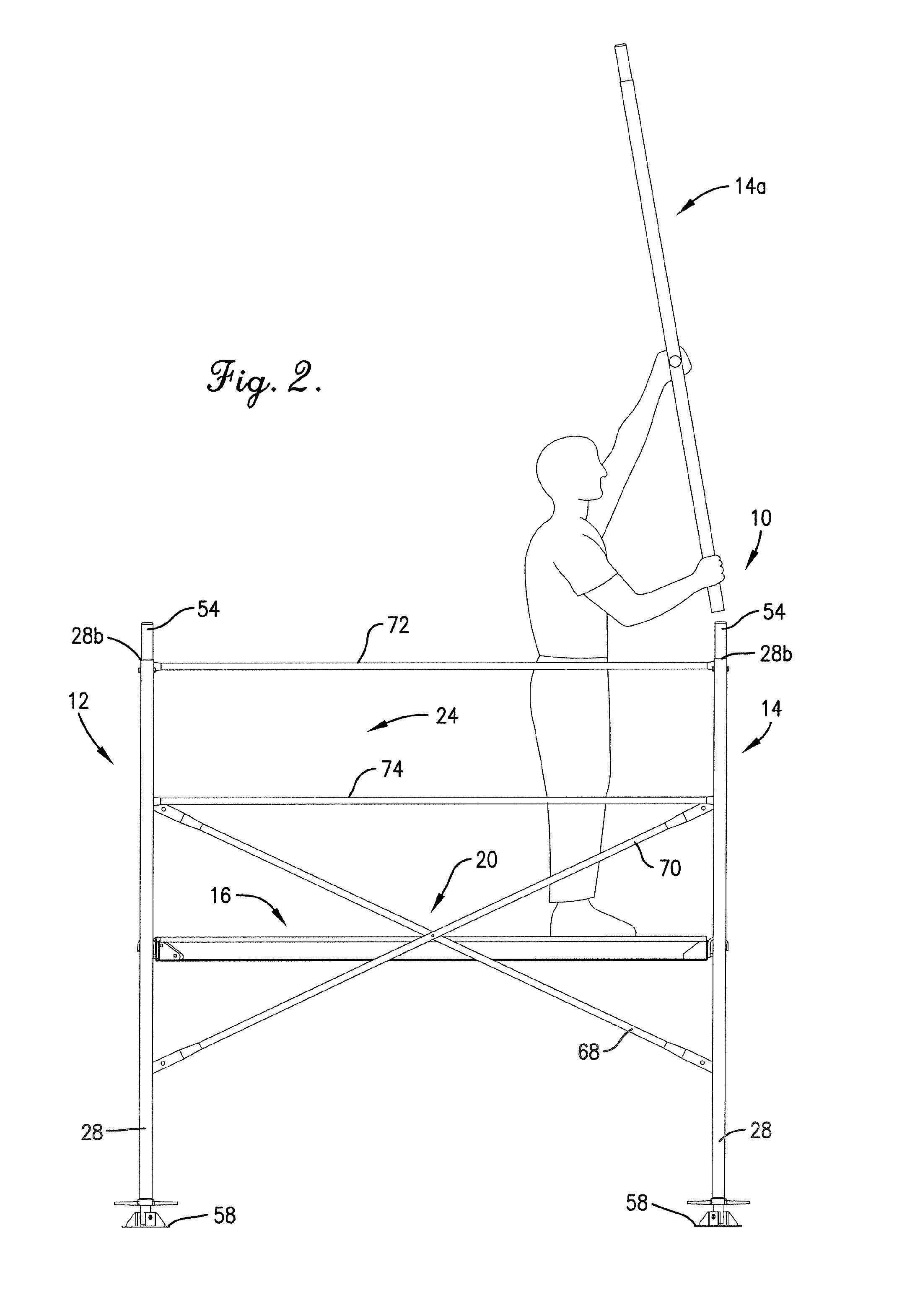

[0024] Turning now to the drawings, the scaffold assembly 10 selected for illustration in FIG. 1 broadly includes a pair of preconstructed end frames 12,14, a personnel platform 16, cross-tie assemblies 18,20, and guardrail assemblies 22,24. As shown, the assembly 10 is a free-standing unit for use on construction sites or in similar contexts.

[0025] In more detail, the end frames 12,14 in the depicted embodiment are mirror images of each other. Thus, only the end frame 12 will be described in detail, with the understanding that the other end frame 14 is similarly constructed. Furthermore, the same reference numerals will be used to identify similar components of the end frame 12 and 14.

[0026] As perhaps best shown in FIG. 4, the end frame 12 preferably includes a pair of upright standards 26,28, each having lower ends 26a,28a and upper ends 26b,28b. In the preferred embodiment, the standards are formed of metal (e.g., steel or Aluminum) and have a circular, tubular configuration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com