Recovery of hydrocarbons using electrical stimulation

a hydrocarbon and electrical stimulation technology, applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of contaminated water disposal, limited sagd methods to about 2000 ft, and sand washing out, etc., and achieve the effect of high pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] An embodiment of the present invention will be described with particular reference to tar or oil sand formations.

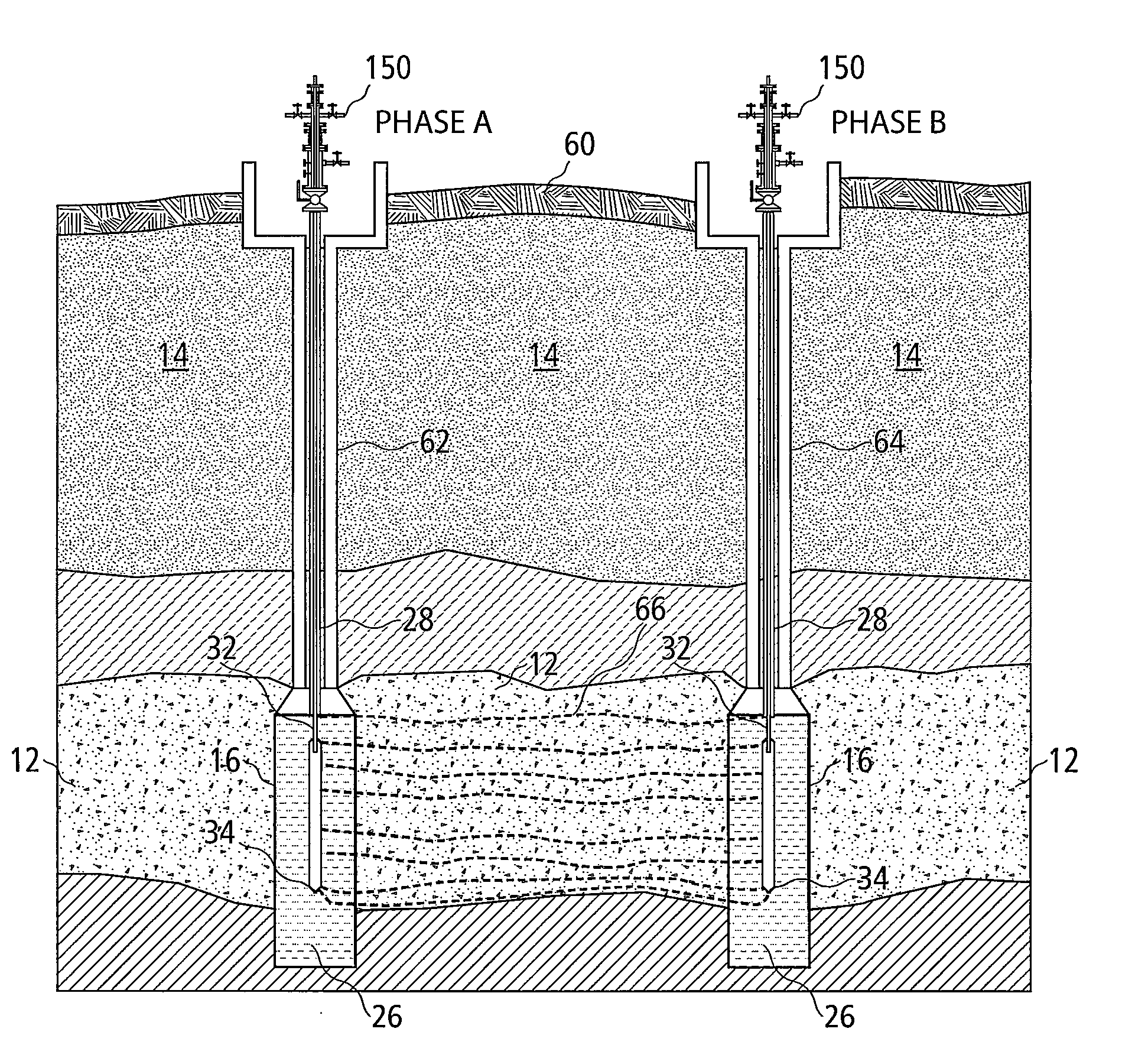

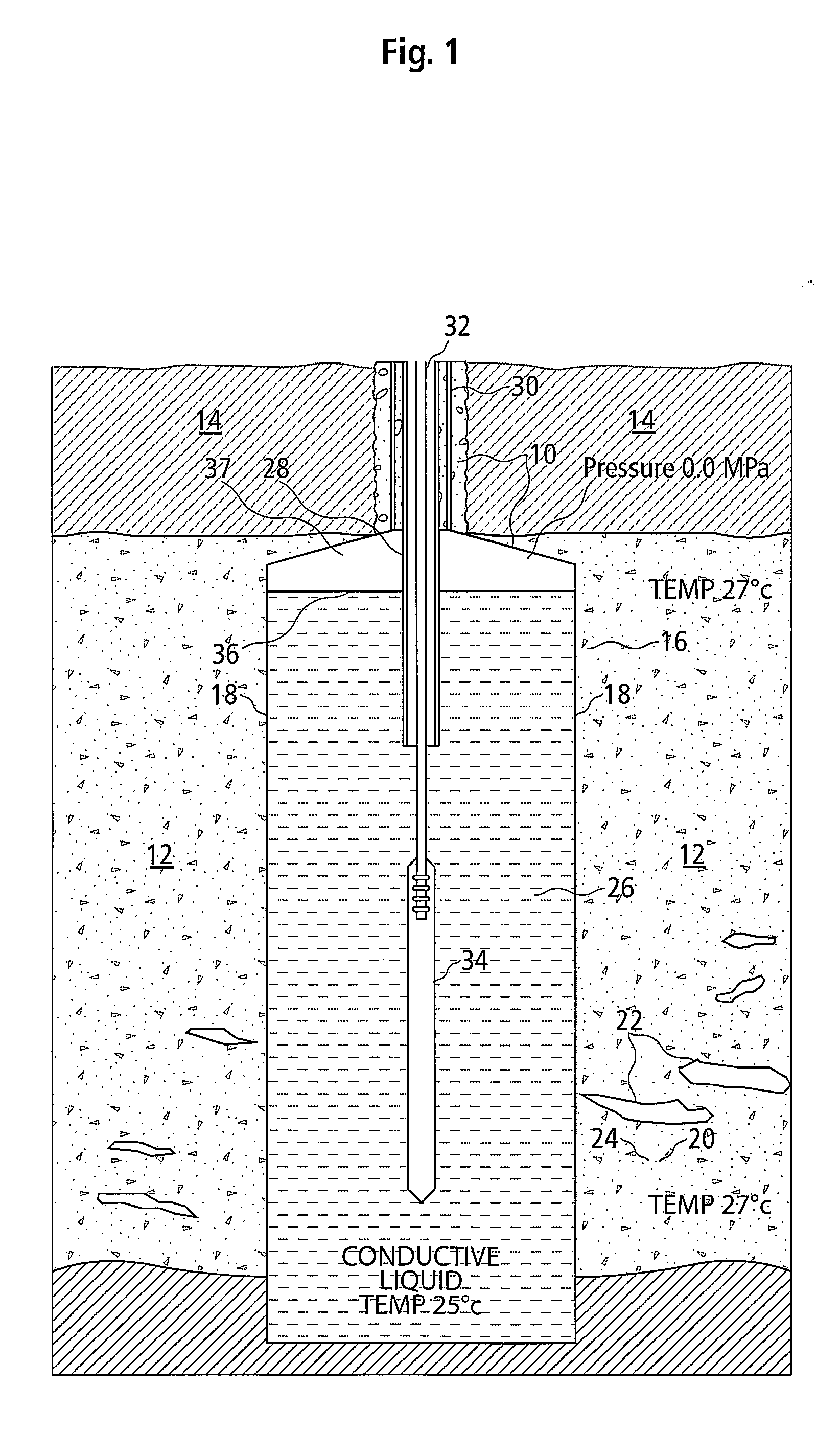

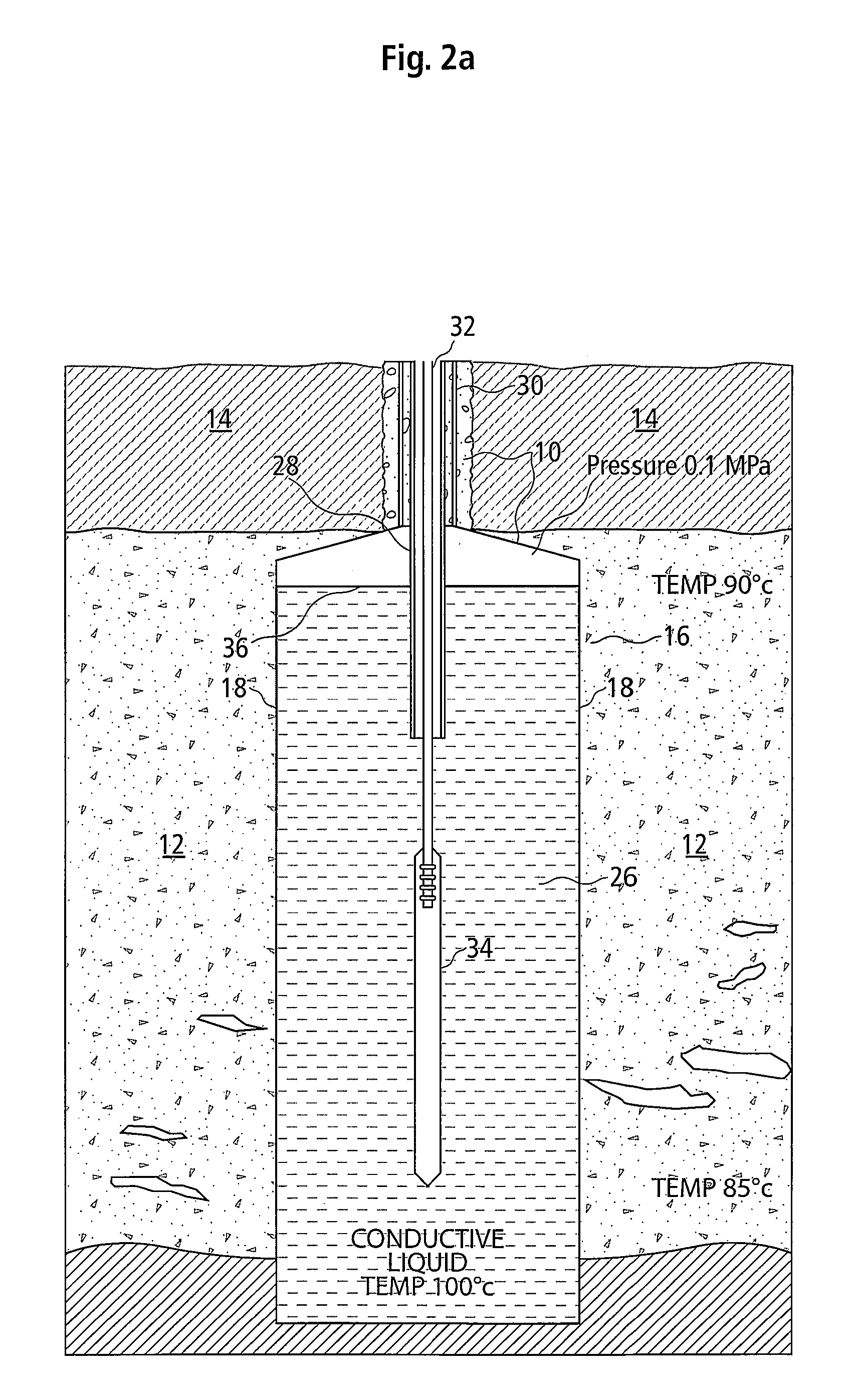

[0079]FIG. 1 illustrates a typical arrangement of a well before electrical power is applied to the formation. Wellbore 10 extends through overburden 14 and into oil (tar) sand formation 12. The bottom portion of wellbore 10 comprises an enlarged production cavity 16 and the walls 18 of production cavity 16 are substantially vertical. In the present embodiment, the well further comprises casing 30 and production pipe or tubing 28, which tubing extends partially into production cavity 16 and through which the conductive liquid 26 is added to the production cavity 16. When bitumen is ultimately produced, the bitumen flows to the surface through production tubing 28. The casing 30 may be insulated from the electrical conductor 32 by suitable insulation as is known in the art (not shown) in order to operate at the voltage and temperatures necessary for the present inve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap