Elastic lace and attachment system for shoes

a technology of elastic lace and attachment system, which is applied in the direction of shoe lace fastening, footwear, fastening, etc., can solve the problems of shoe that fits loose at the toes, strained across the instep, and most users do not properly loosen and tighten the laces all the way down the shoe each, so as to achieve the effect of permanently eliminating the need for tying a shoe, superior fit and comfort, and locking the tension in the la

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

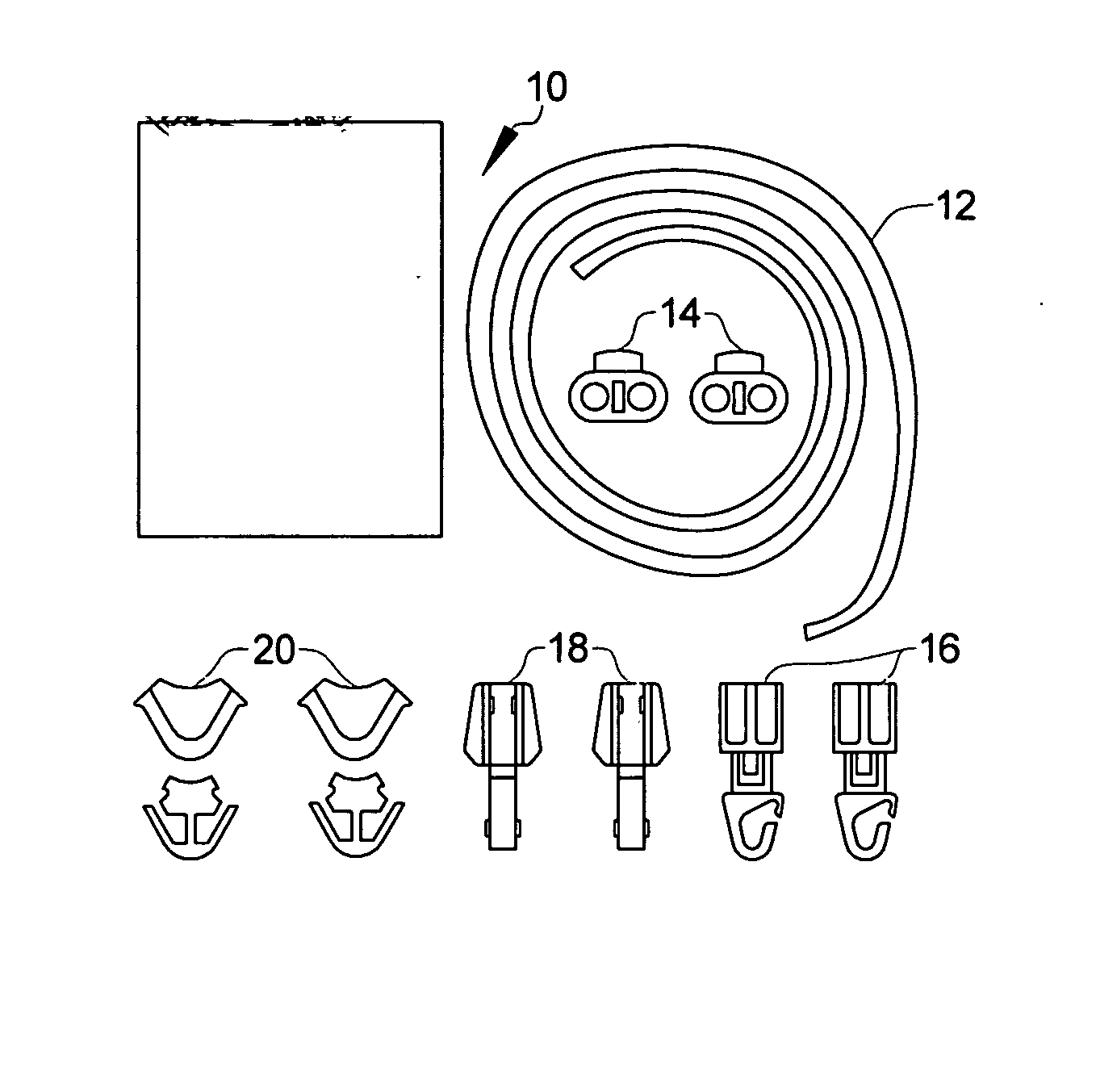

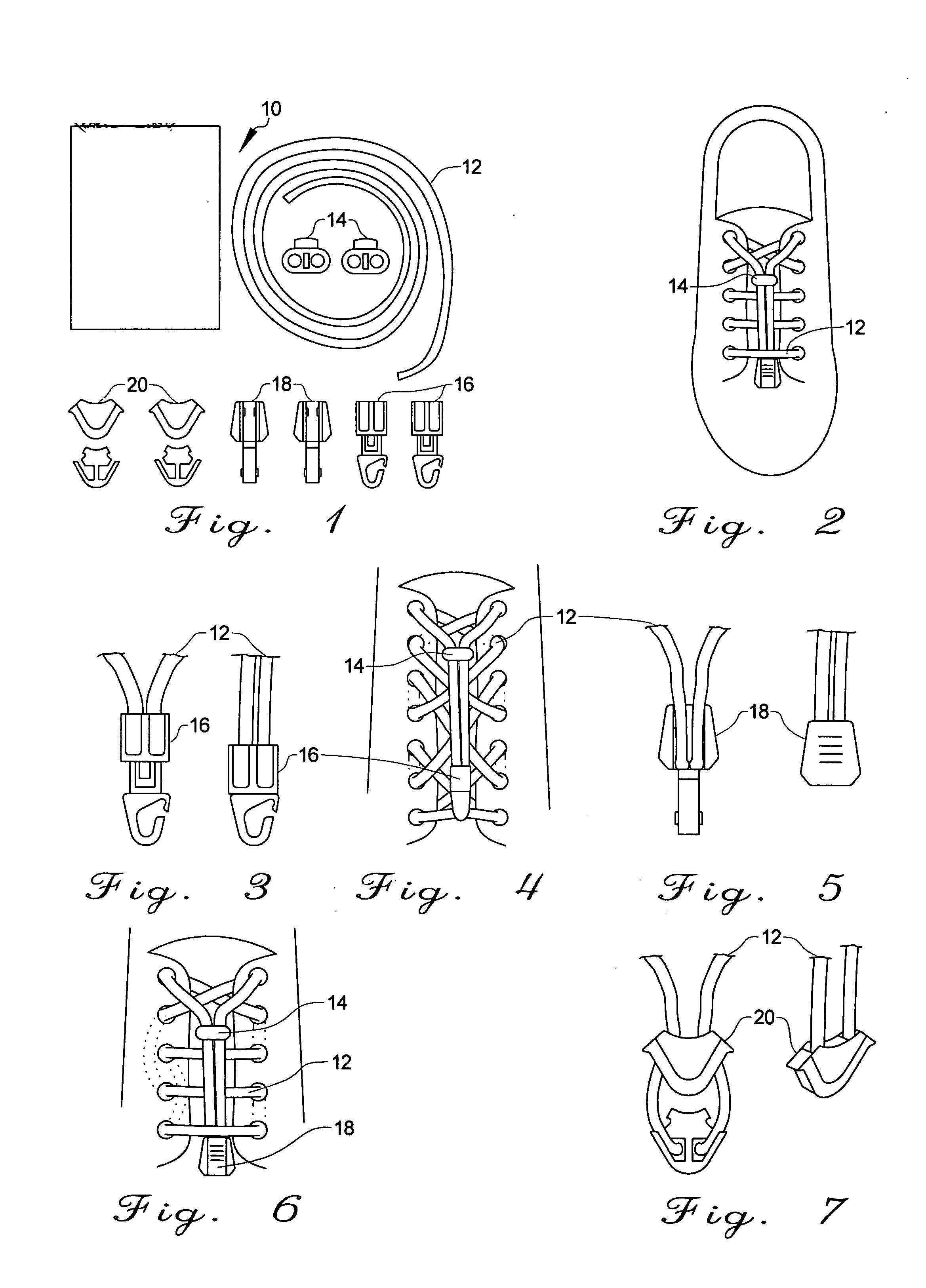

[0032] Referring to FIG. 1, a kit for converting a lace-up style shoe to a slip-on style shoe is shown and is generally designated by numeral 10. Kit 10 typically contains two elastic shoelaces 12, one for each shoe. In the preferred embodiment, elastic shoelaces 12 are of cylindrical shape and are composed of a natural rubber core, braided externally with nylon in one of any number of colors. However, elastic shoelace 12 could alternatively be composed of any number of elastomeric material combinations in any number of shapes as would be apparent to one skilled in the art. Referring to FIG. 2, elastic shoelace 12 is installed into a lace-up style shoe in any number of configurations available to lace up a shoe as would be apparent to one skilled in the art.

[0033] Referring back to FIG. 1, kit 10 contains two tensioners 14, one for each shoe. In the preferred embodiment, tensioner 14, contains an outer member, an inner member and a spring. Both the outer and inner member have two t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com