Cushioning system for footwear

a cushioning system and footwear technology, applied in footwear, clothing, applications, etc., can solve the problems of inability to vary the cushioning, less effective in the forefoot area, and discomfort and injury, and achieve the effects of low manufacturing cost, convenient and efficient manufacturing and marketing, and durable and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

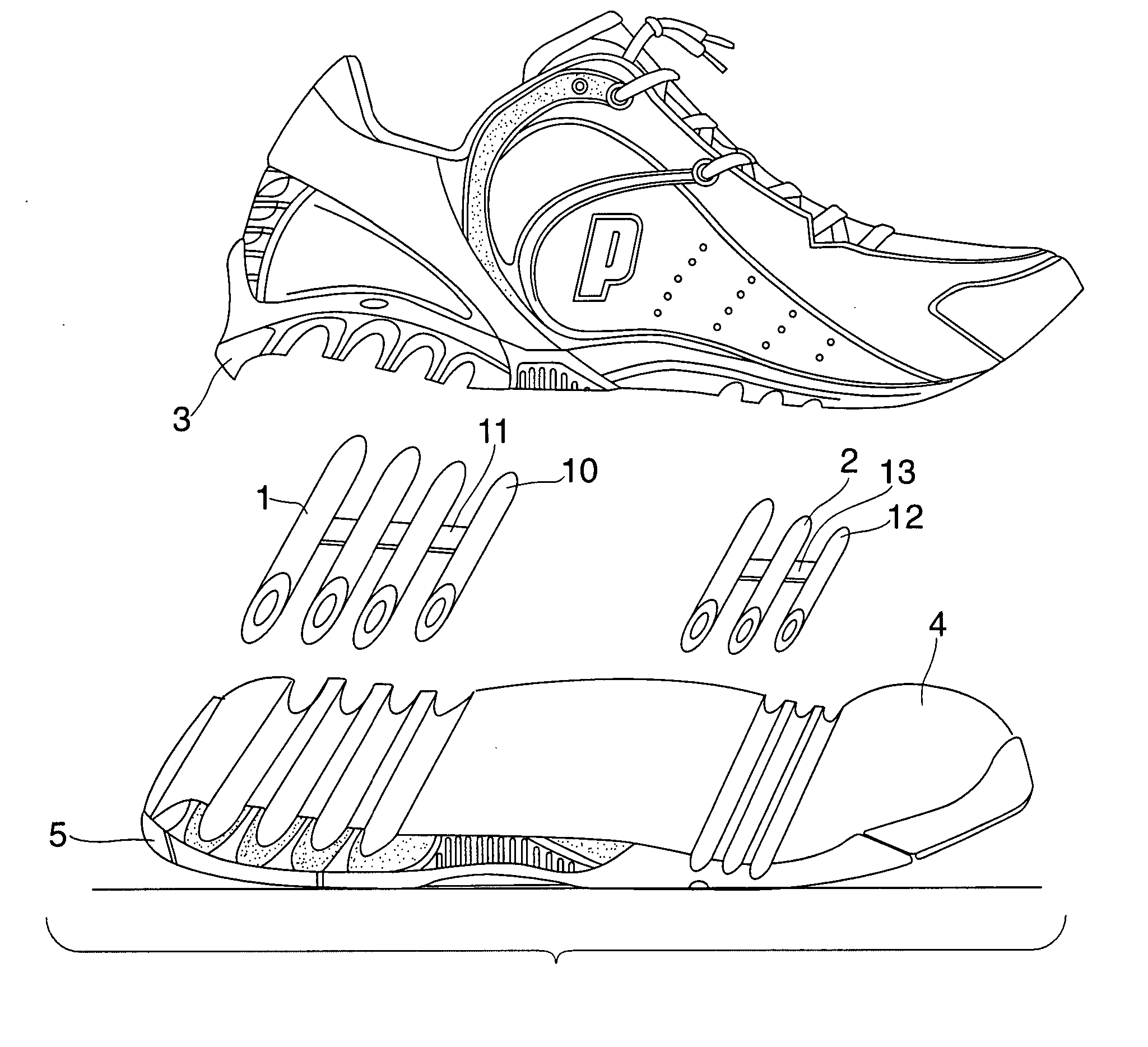

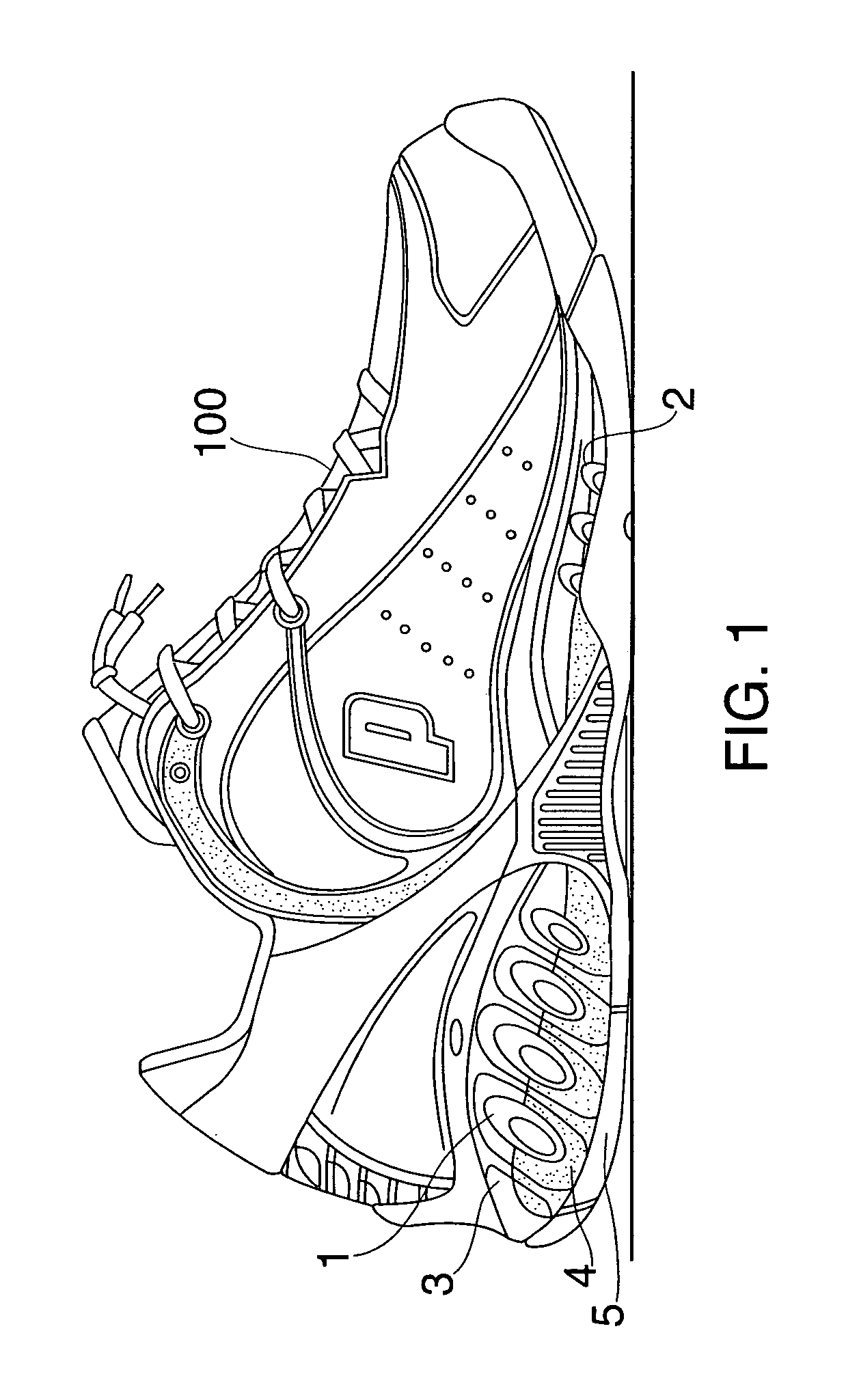

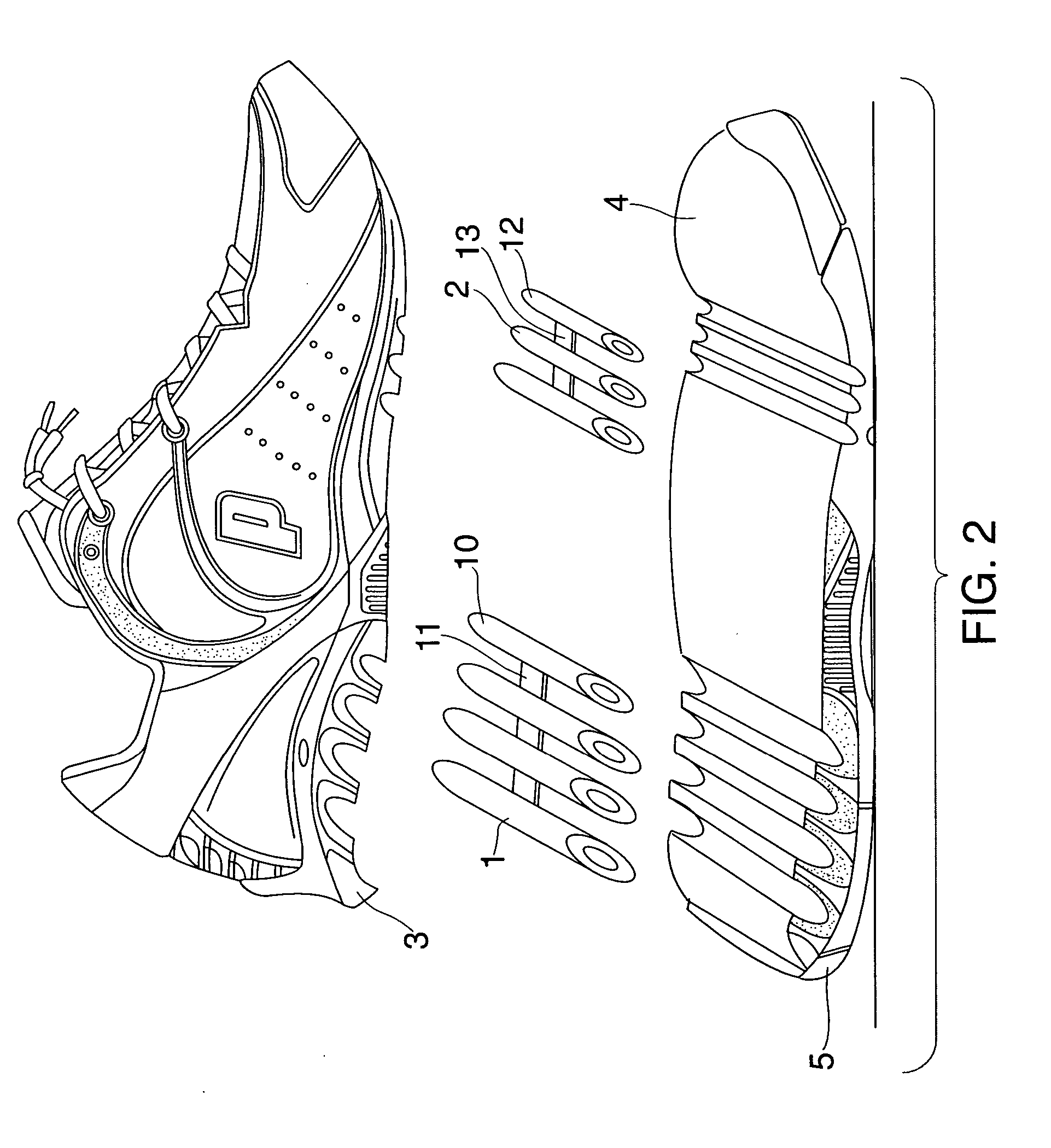

[0035] With reference now to the drawings, and in particular to FIGS. 1 through 9 thereof, the preferred embodiments of footwear according to the invention, generally designated by the reference numeral 10, will be described.

[0036] The present invention uses pre-molded hollow tubes whose function is to vary the amount of cushioning of the shoe. The tubes, being circular or oval in cross section, are preferably fabricated using resilient plastic or elastomeric materials, and act as arches or springs to absorb the force of impact. The amount of cushioning desired depends on the material, geometry, location, and orientation of each tube.

[0037] The material used for the tubes can vary the amount of cushioning achieved. For example, if a high degree of cushioning is desired, then the material should be an elastomeric grade material with a Shore A hardness of 30-50 such as Thermoplastic Polyurethane(TPU), or Thermoplastic Rubber(TPR), or Thermoplastic Elastomer (TPE). An example would b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com