Anode plate for a field emission display device

an emission display and anode plate technology, applied in the direction of cathode-ray/electron beam tube electrical connection, discharge tube luminescnet screen, tube with screen, etc., can solve the problem of defective display panels, no study of the pattern of the anode conducting band, and the use of the flexibility of the electrically conductive layer. , to achieve the effect of enhancing the sealing strength between the plates and facilitating the operation of the display circui

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

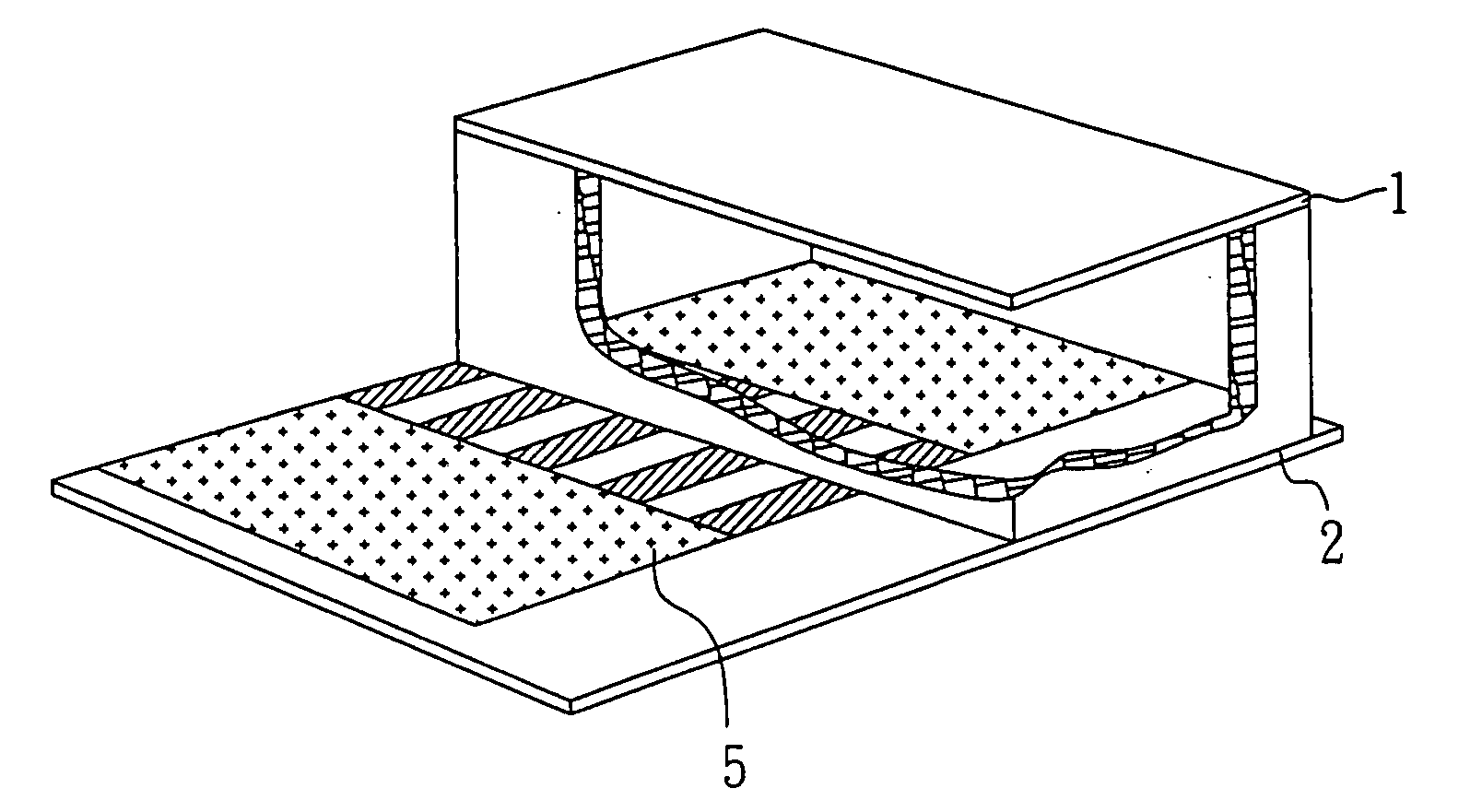

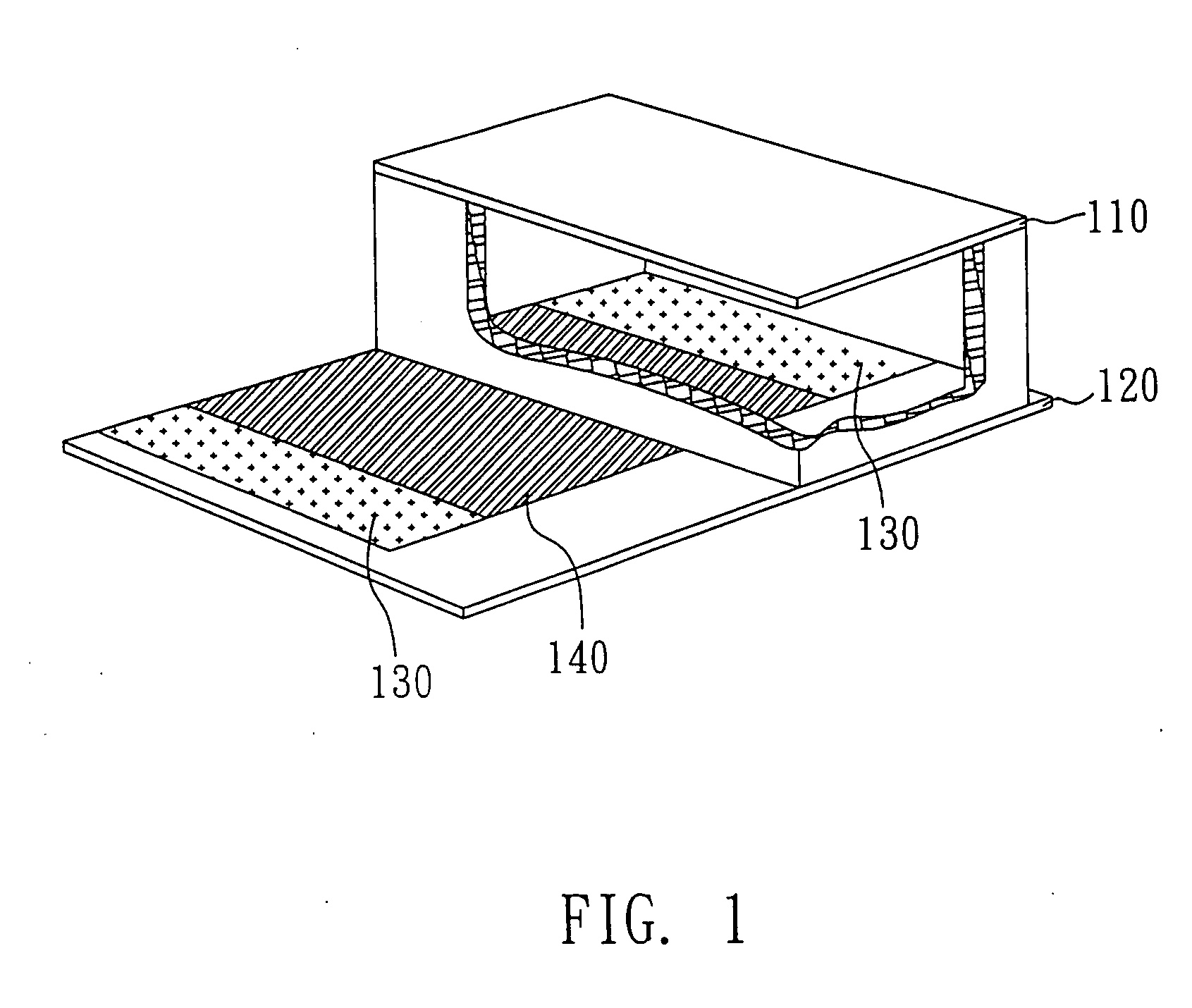

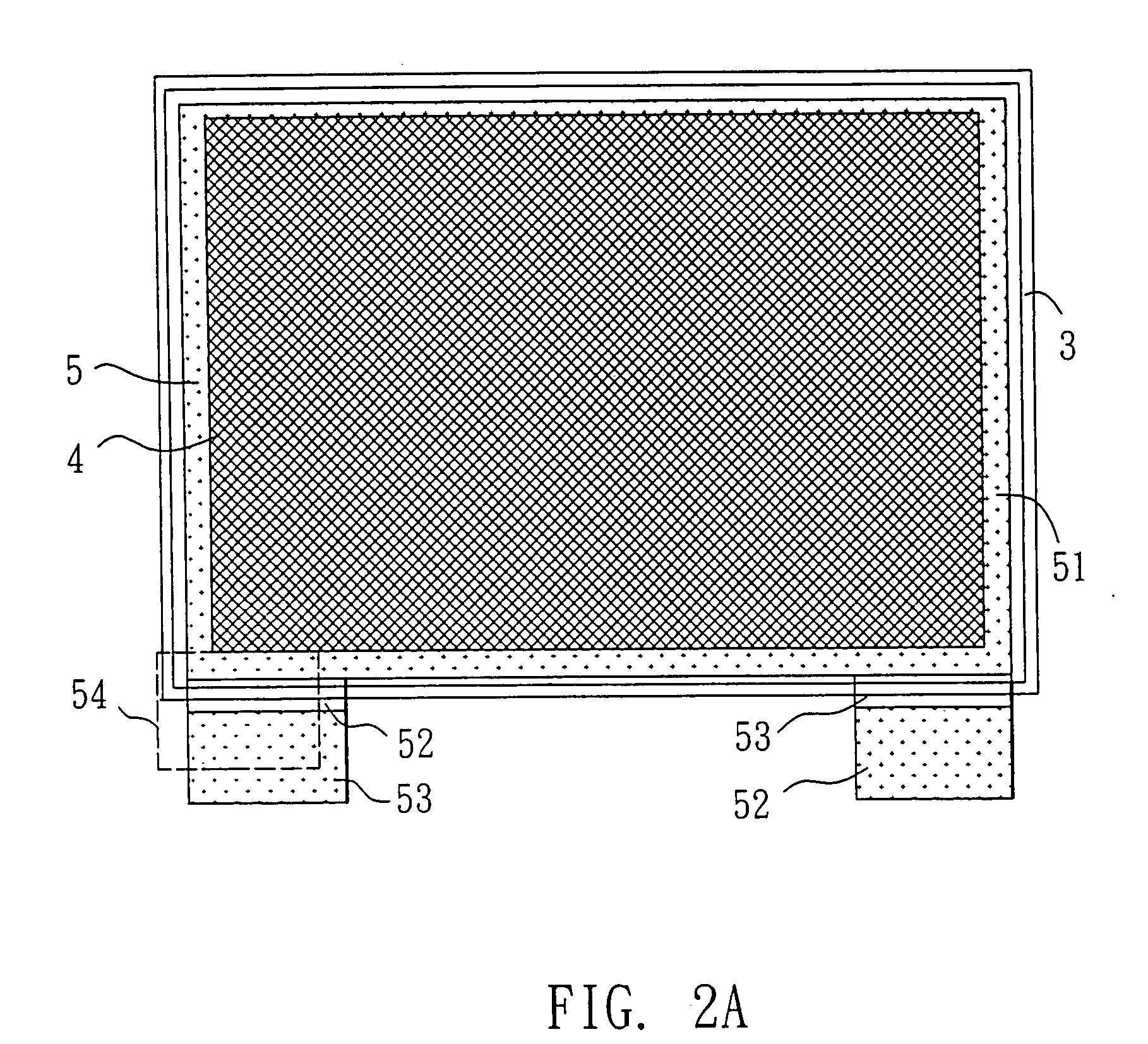

[0021] With reference to FIGS. 2A, 2B, and 2C, there are shown the sealing of the cathode plate and the anode plate having an interspacing conductive band of one preferred embodiment of the present invention. FIG. 2B is the enlarged view of block 54 in FIG. 2A. In the present embodiment, on the cathode plate 1 of the field emission display device, there are formed a plurality of carbon nanotubes for generating the electrons and a plurality of transistors (not shown). Each of the transistors is corresponding to one of the carbon nanotubes respectively and controls the switches of the pixel. A fluorescent layer 4 and an electrically conductive layer 5 are formed on the anode plate 2. The electrically conductive layer 5 is a patterned ITO glass, which is formed through thin film deposition followed by a photolithography process. The electrically conductive layer 5 includes an anode conductive layer 51 and an interspacing conductive band 52, wherein the anode conductive layer 51 is sand...

embodiment 2

[0023] With reference to FIG. 4, there is shown the sealing of the cathode plate and the anode plate having an interspacing conductive band of another preferred embodiment of the present invention. The field emission display device of the present embodiment includes the cathode plate 21, the anode plate 22, the side frame 23 mounted between the cathode plate 21 and the anode plate 22 for forming a fixed space between the cathode plate 21 and the anode plate 22, a fluorescent layer formed at the inner side of the side frame 23 on the anode plate 22, an adhesive layer, e.g. a frit layer sandwiched between the cathode plate 21 and the side frame 23 as well as the anode plate 22 and the side frame 23 for bonding and sealing, a plurality of carbon nanotubes located on the cathode plate 21 for generating the electrons, and a plurality of transistors also located on the cathode plate 21 for controlling the switches of the pixel of the field emission display device. The electrically conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com