Insole board for high-heel shoe

a technology for shoe soles and high-heels, which is applied in the field of high-heels shoes, can solve the problems of increasing affecting the quality of shoes, and affecting the appearance of shoes, so as to reduce the production time and cost of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

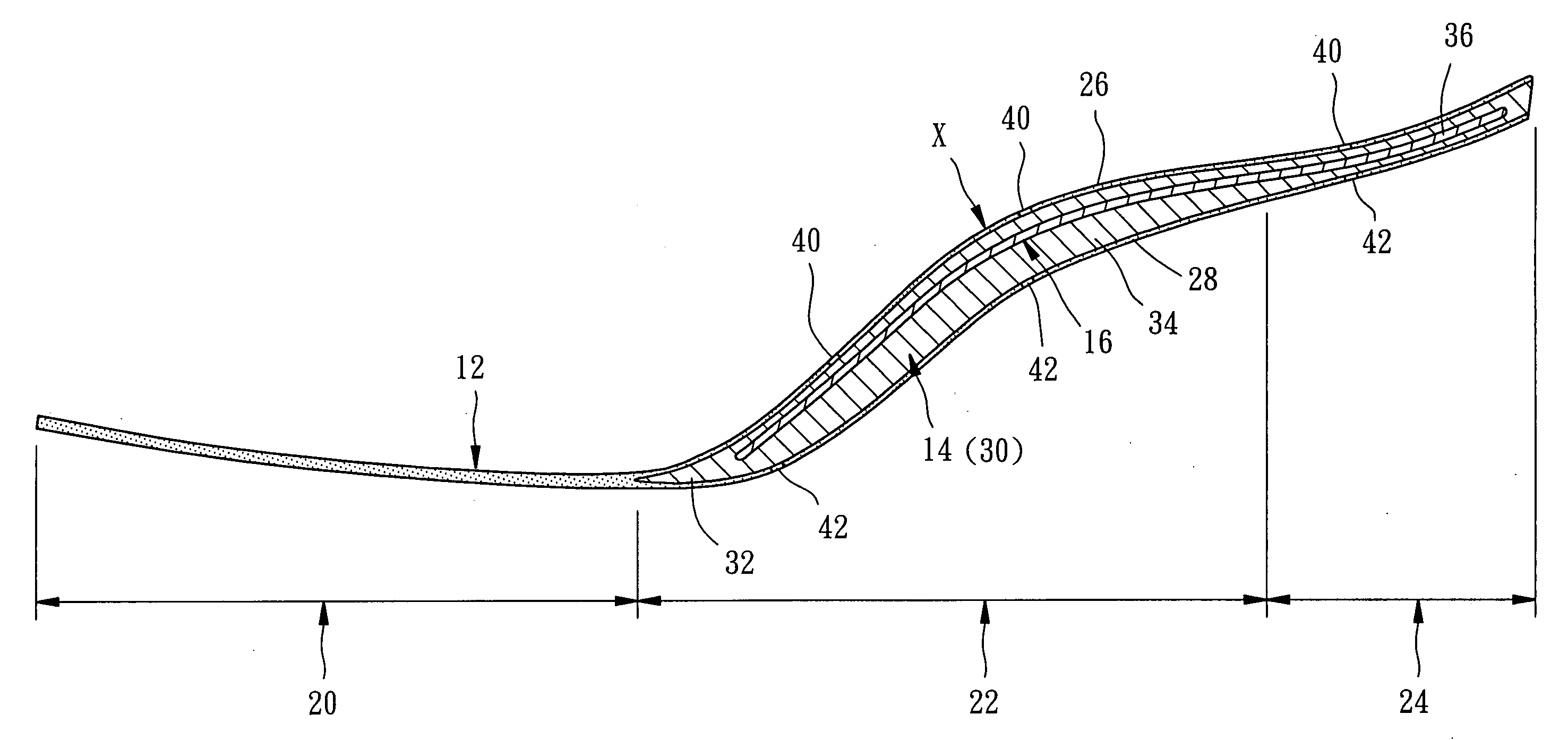

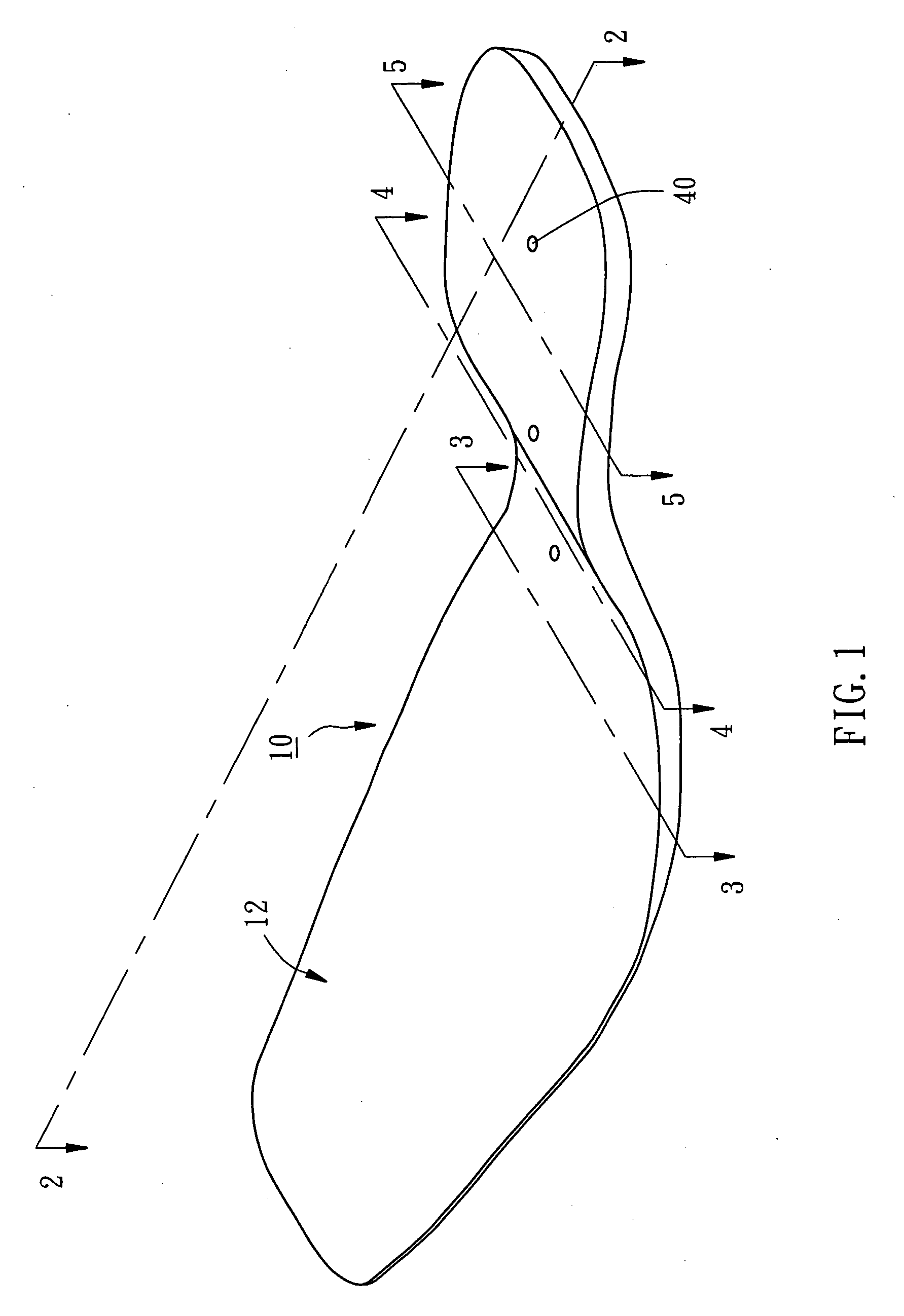

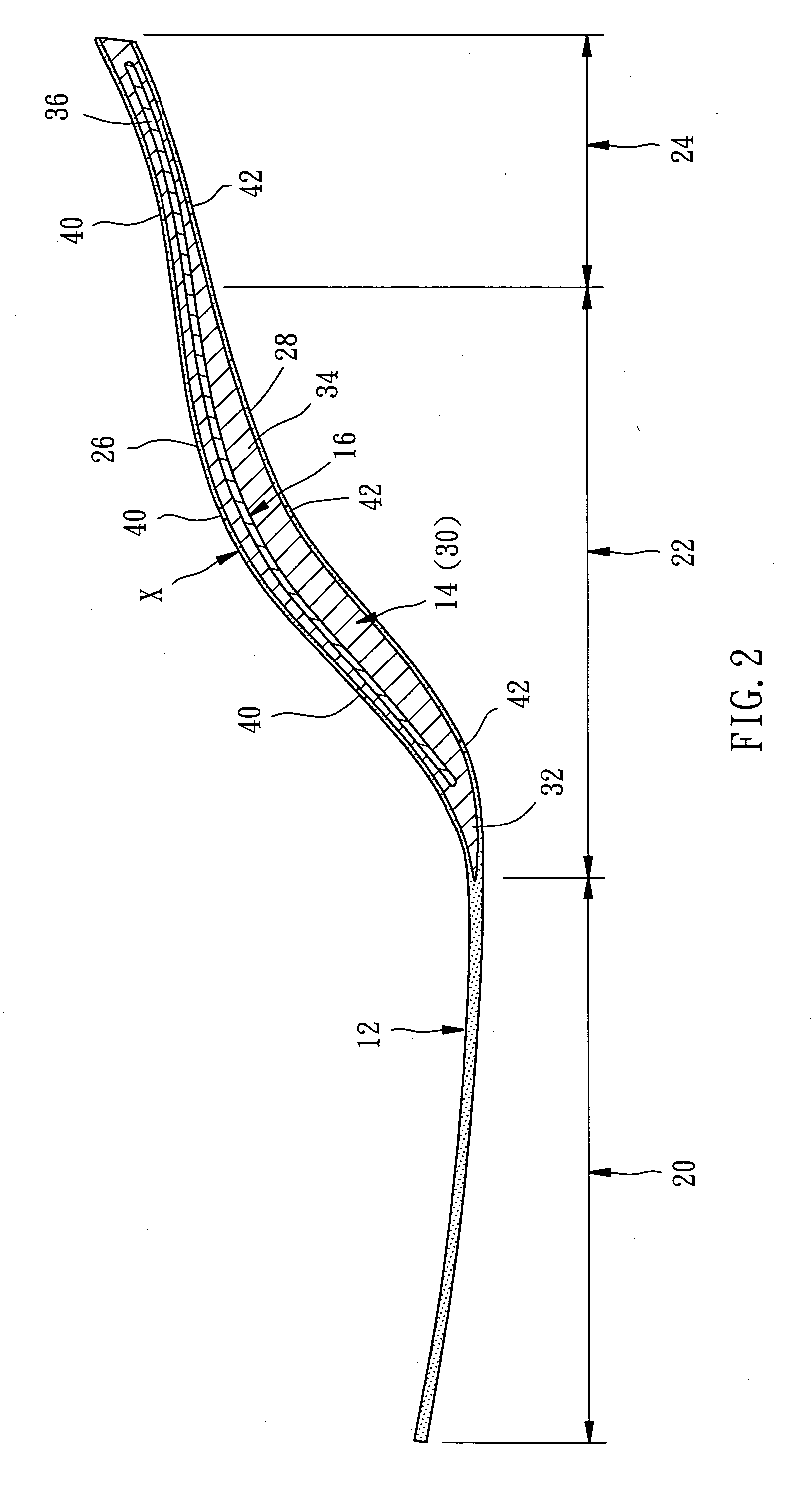

[0019] Referring to the drawings, an insole board for high-heel shoe 10, according to a preferred embodiment of the present invention, includes a board member 12, a plastic molded member 14, and a rigid supporting member 16.

[0020] The board member 12 has a forefoot portion 20, a midfoot portion 22 and a heel portion 24. The midfoot portion 22 and the heel portion 24 are split into an upper layer 26 and a lower layer 28 to form a space 30 to enclose the plastic molded member 14.

[0021] The plastic molded member 14 has a tapered fore-portion 32, an arched mid-portion 34 and a recessed heel-portion 36. The arched mid-portion 34 has a thickness which is gradual decreased respectively from a top point X thereof to each end thereof to connect the tapered fore-portion 32 and the recessed heel-portion 36.

[0022] The contour of the plastic molded member 14 is designed to have a downward curve extended from the top point X to the tapered fore-portion 32 and a second downward curve extended f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com