Articulating headrest assembly

a headrest and assembly technology, applied in the field of headrest assembly, can solve the problems of increasing the possibility of serious occupant injury during a vehicle crash, short-term muscle and ligament trauma or long-term nerve damage, and achieve the effect of reducing manufacturing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

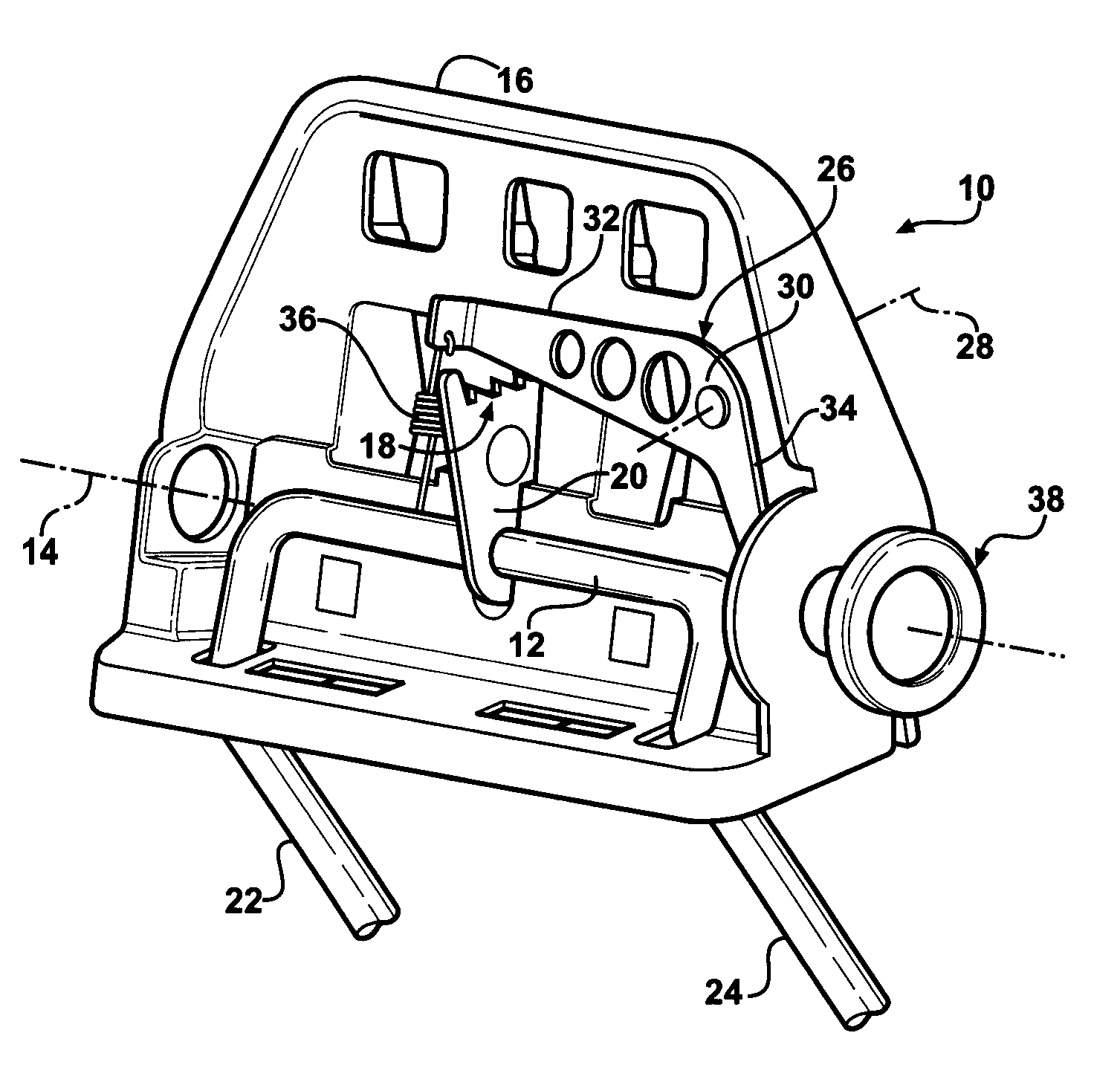

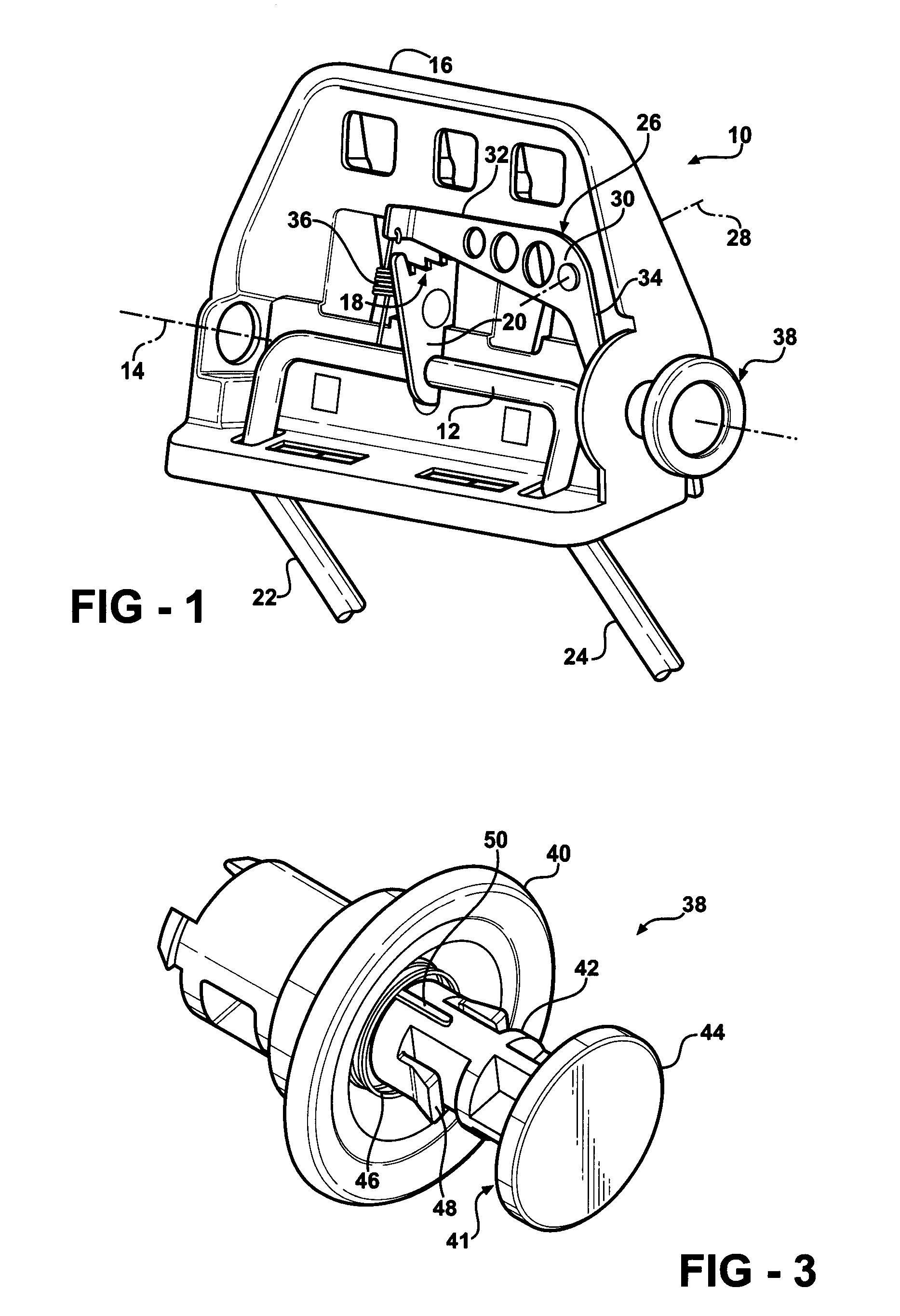

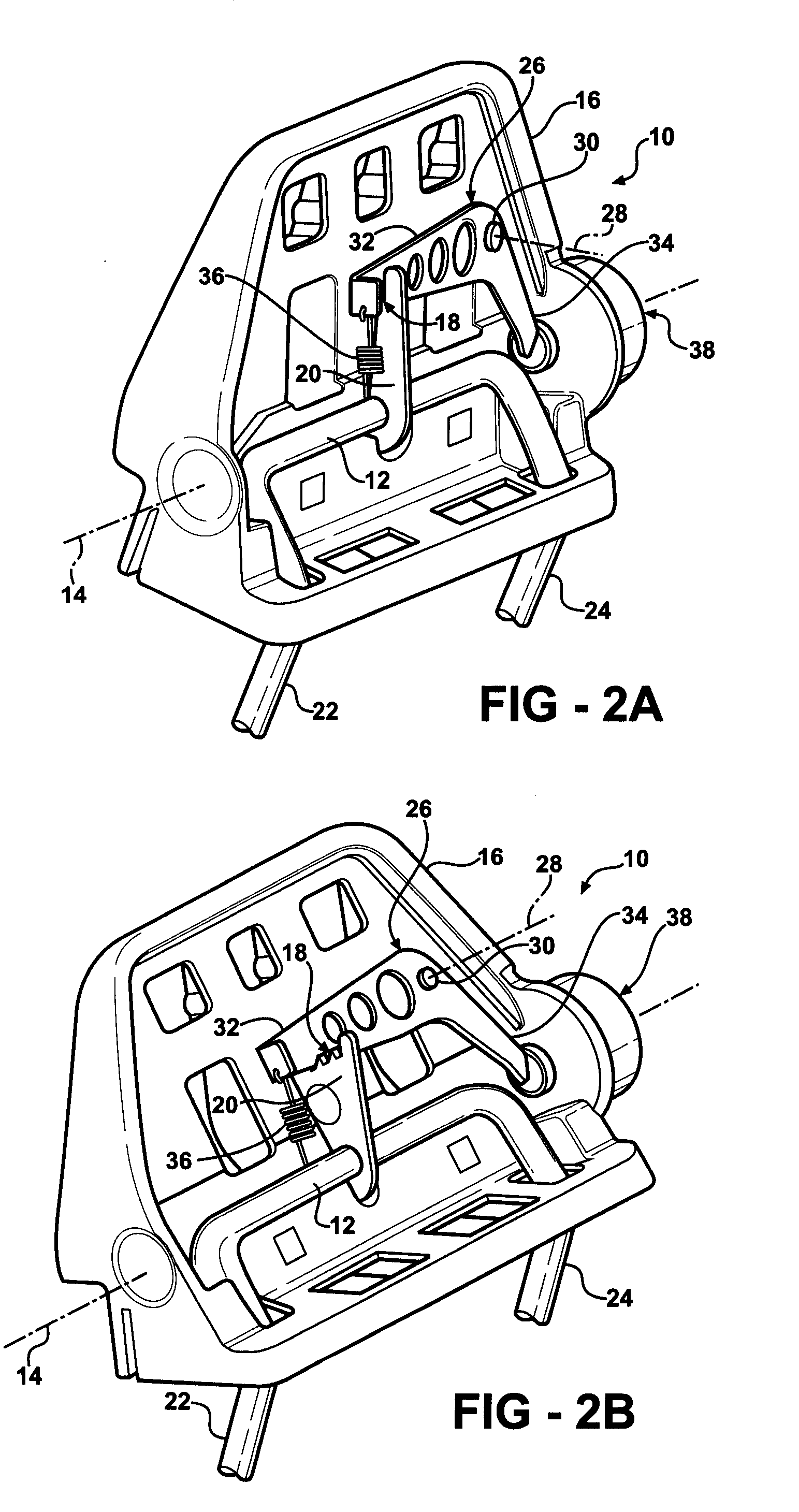

[0017] Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a headrest assembly rotatable to a plurality of positions is shown generally at numeral 10. As shown in FIGS. 1, 2A, and 2B, the headrest assembly 10 includes a support 12 defining a horizontal axis 14. A shell 16 is rotatably mounted to the support 12 about the horizontal axis 14. The shell 16 may also include a cover (not shown) to hide the inside of the headrest assembly 10 and provide a cushioned surface. Preferably, the support 12 extends laterally through the shell 16 along the horizontal axis 14. However, those skilled in the art realize that the support 12 may be spaced from the horizontal axis 14. The support 12 defines a plurality of notches 18 and each notch is associated with one of the positions about the horizontal axis 14. The notches 18 are fixed relative to the support 12. In other words, the notches 18 do not rotate about the horizontal axis 14 as the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com