Electrical terminal

a technology of electric terminals and terminals, applied in the direction of contact members penetrating/cutting insulation/cable strands, electrical apparatus, fastening/insulating connecting parts, etc., to achieve the effect of simple removal and simple insertion of two conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

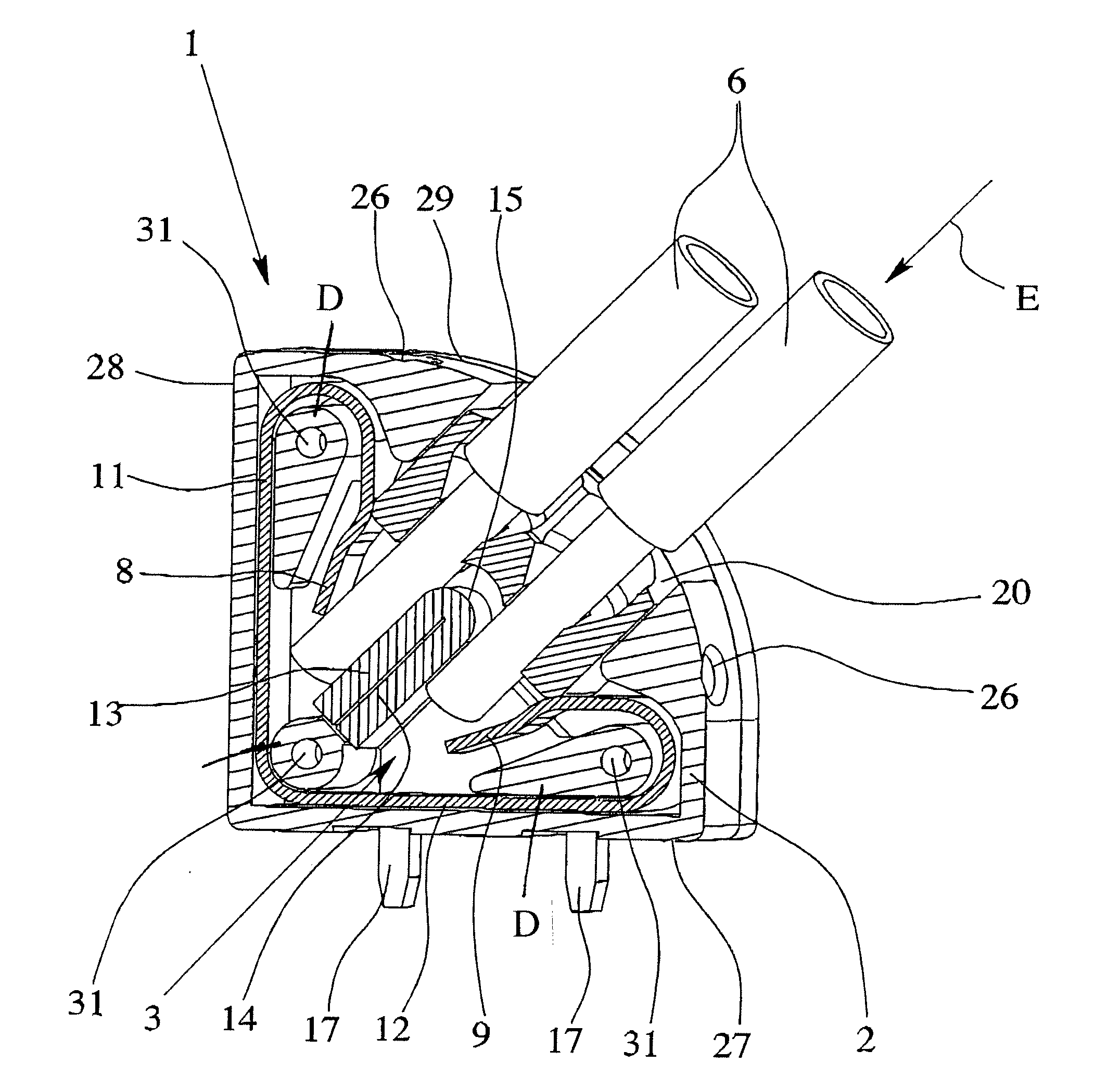

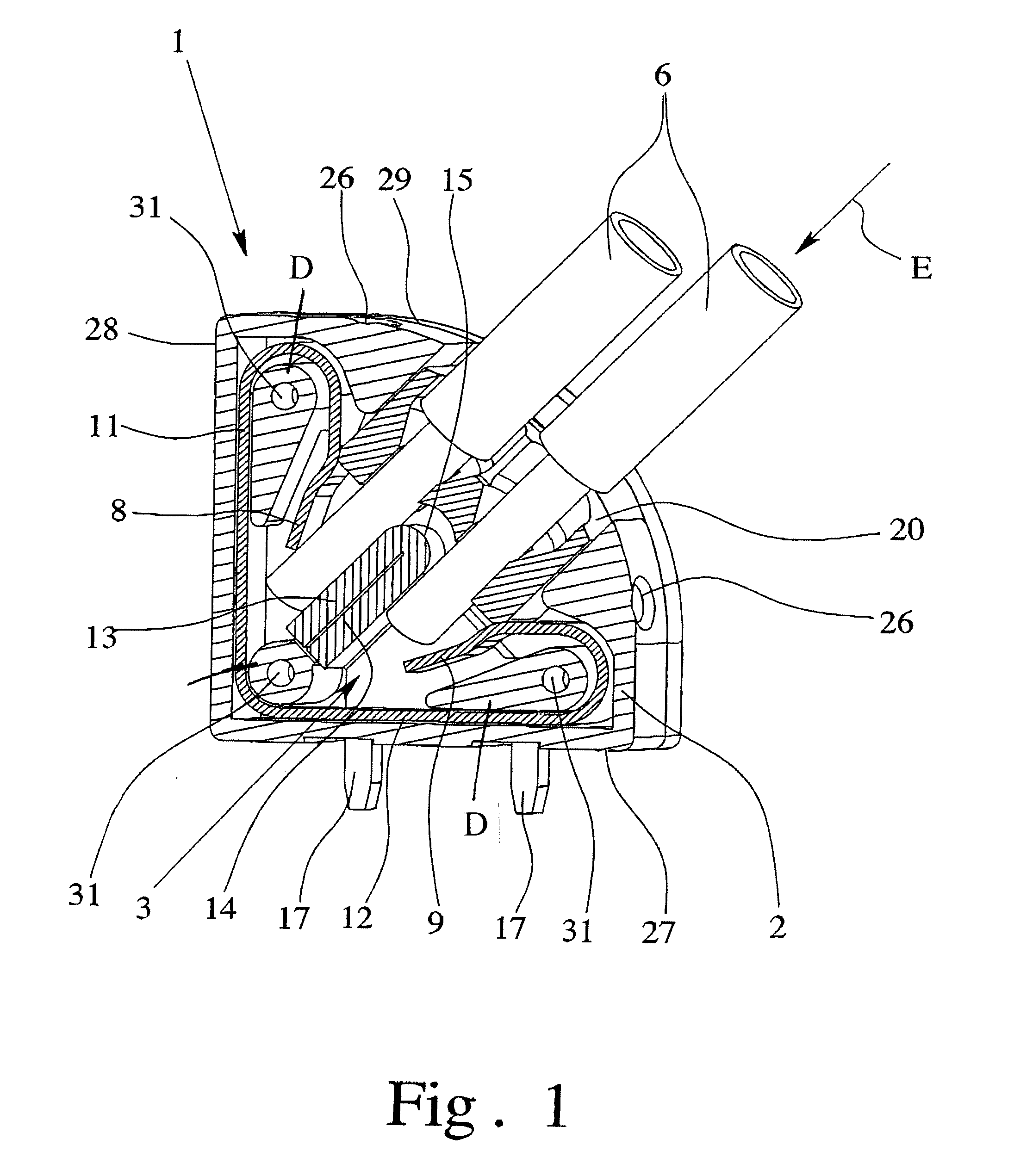

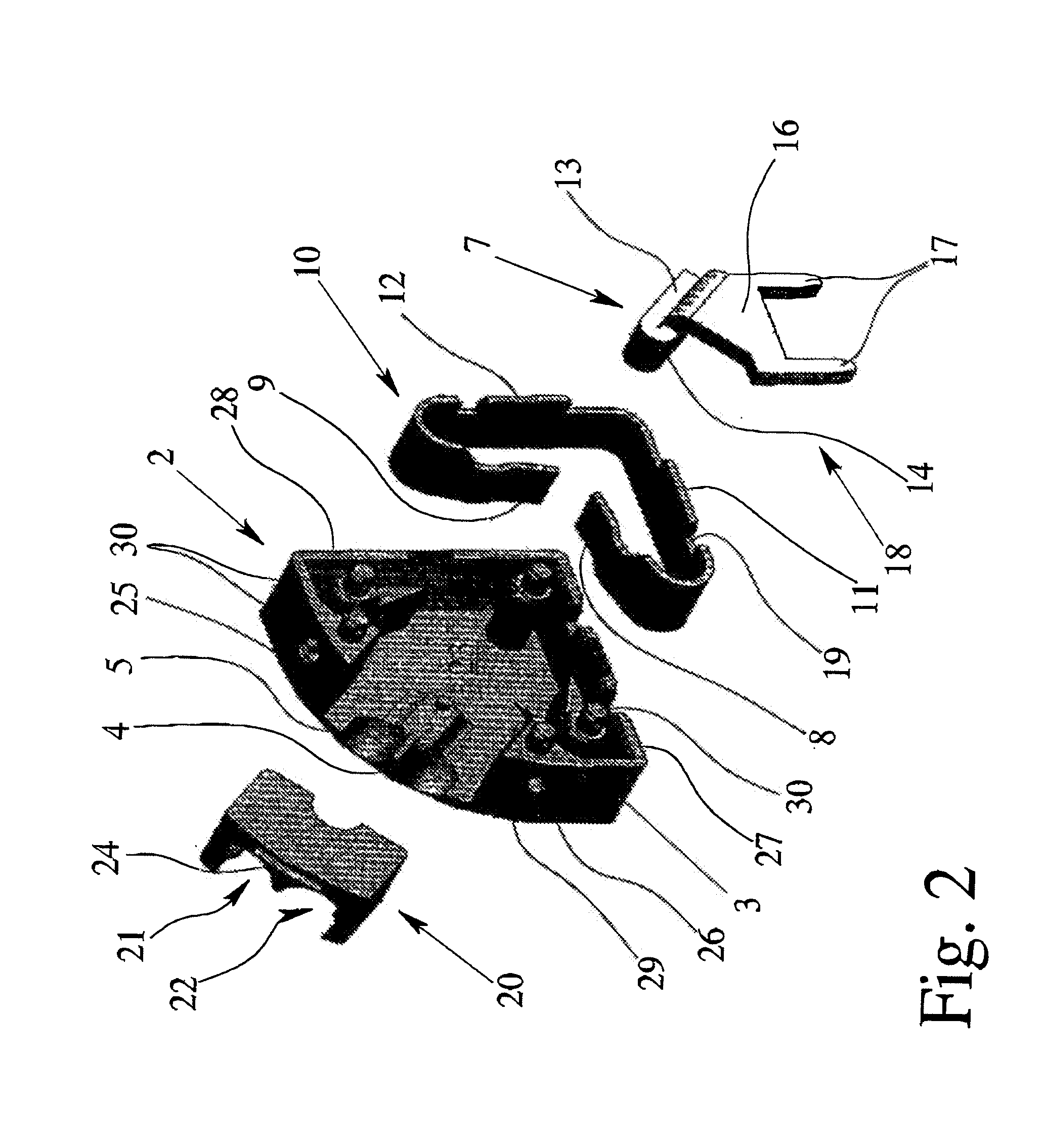

[0026]FIG. 1 shows an electrical terminal 1 with a housing 2 which is made of an insulating material and in which a terminal chamber 3 and two conductor inlets 4, 5, leading into the terminal chamber 3, are formed for two electrical conductors 6 to be connected. In the terminal chamber 3, there is a respective conductor connection arrangement for each conductor inlet 4, 5; the connection arrangements each comprise a current bar 7 and a clamping leg 8, 9, a respective clamping leg 8, 9, forming a spring force clamping terminal for an electrical conductor 6 to be connected together with a facing side of the current bar 7. The two clamping legs 8, 9 are part of a clamping spring 10 which also has two contact legs 11, 12 which, on the one hand, are each connected to a respective clamping leg 8, 9, and on the other hand, are connected to each other. As is apparent from FIG. 1, the two contact legs 11, 12 run essentially perpendicular to one another, the contact legs 11, 12 adjoining an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com