Lacing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

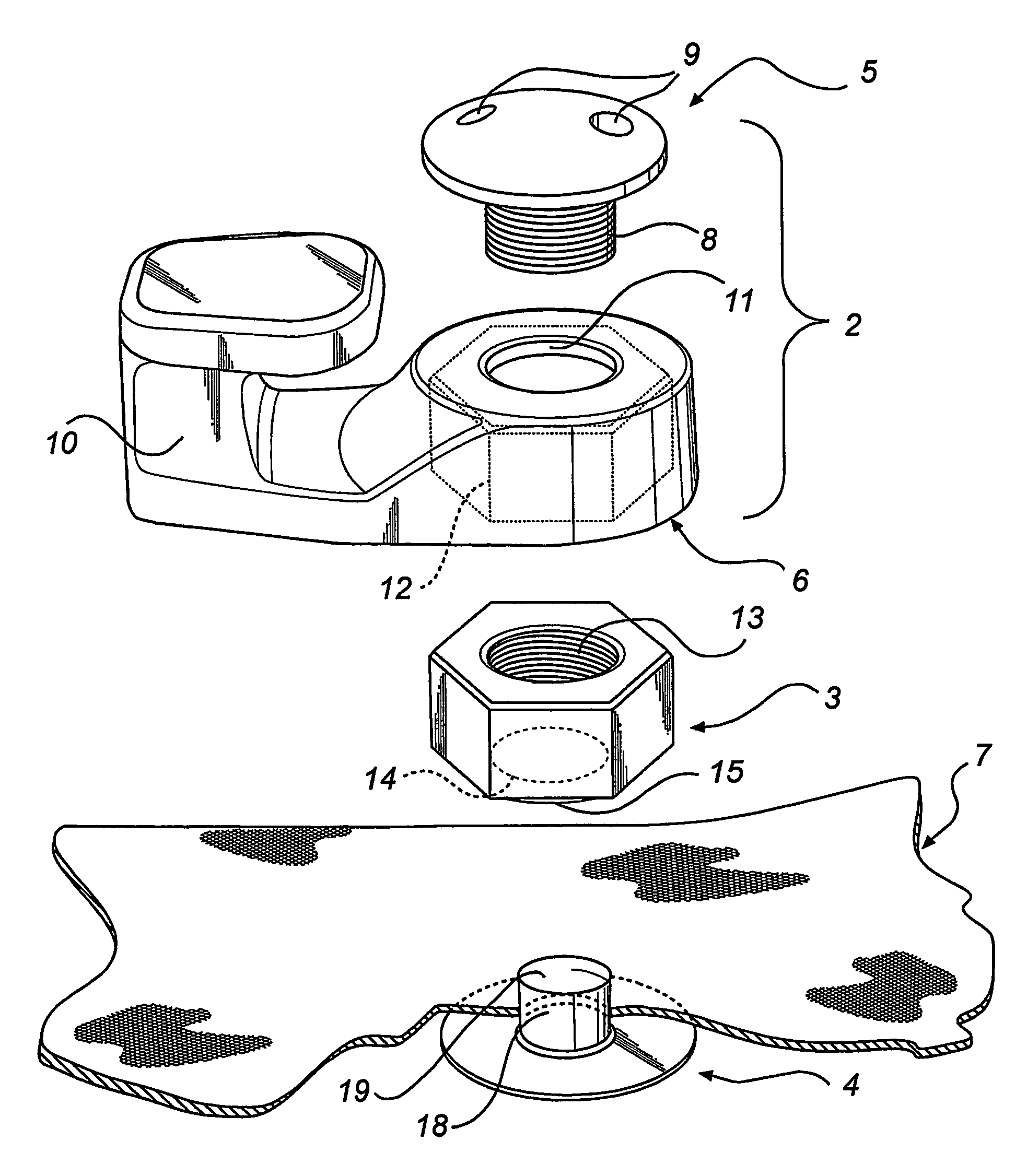

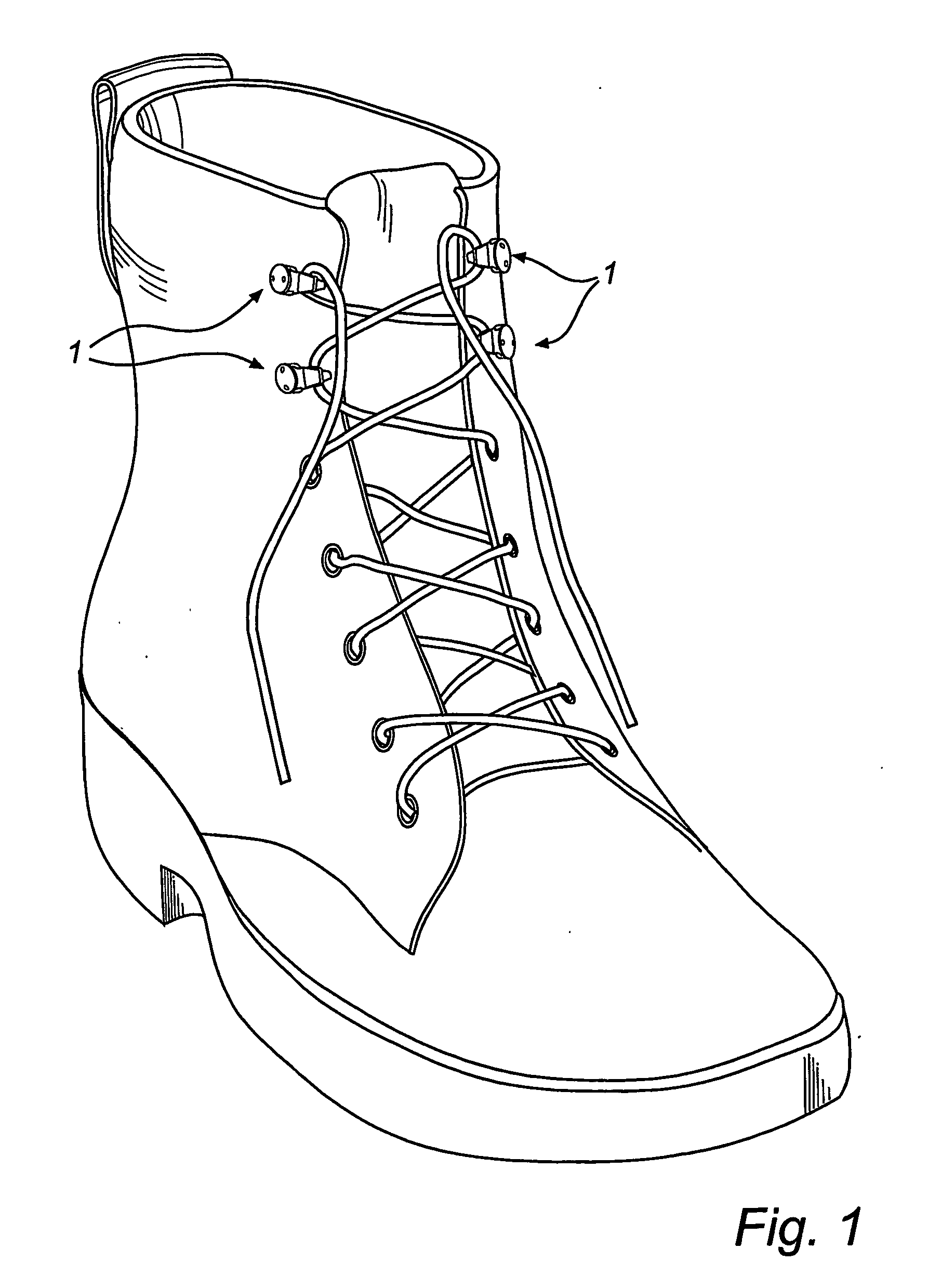

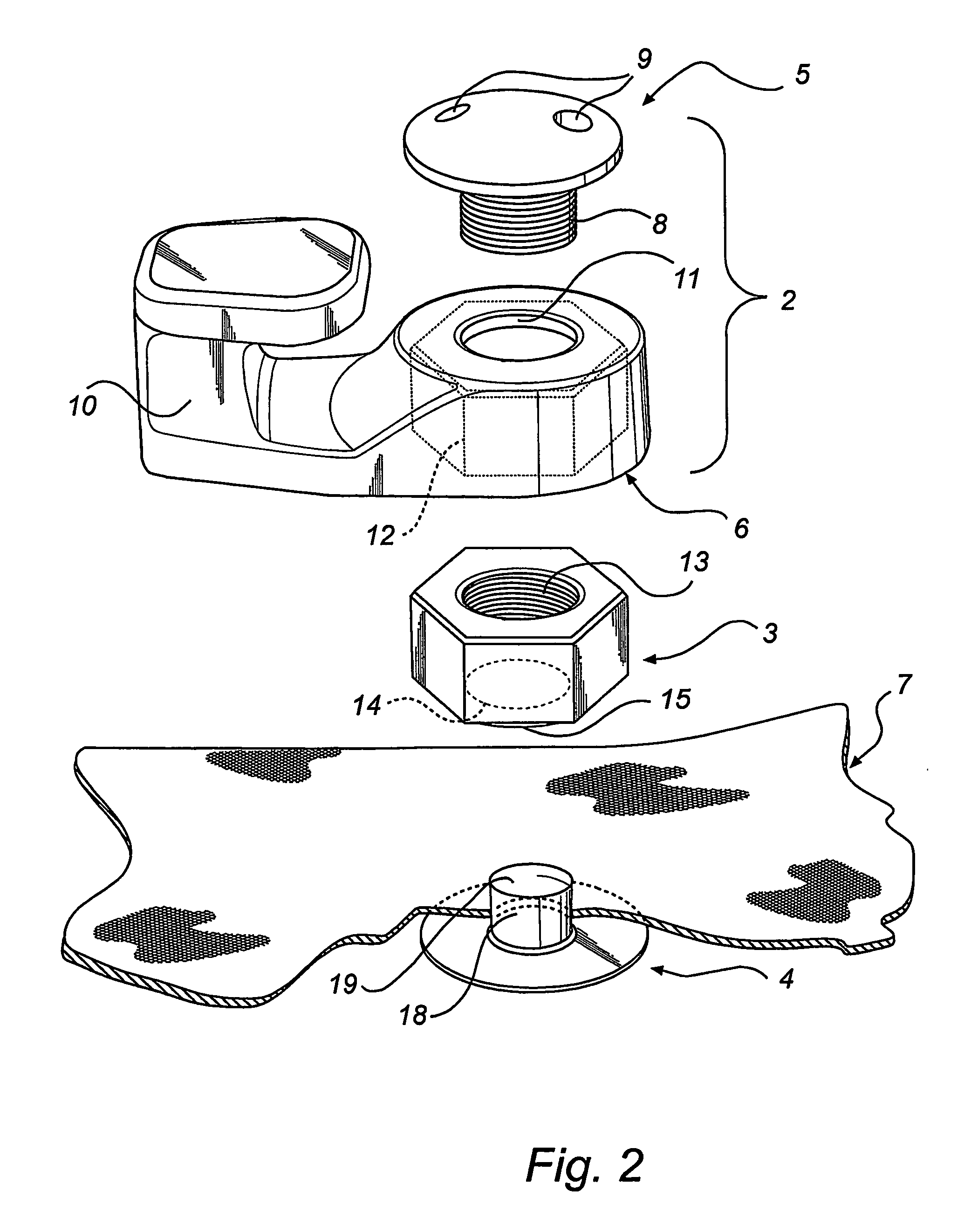

[0014]FIGS. 2-3 illustrate a lacing device 1 according to an embodiment of the invention, which comprises a lace holding part 2, an intermediate fastening element 3 and an inner fastening element 4. The lace holding part 2 in turn comprises an outer fastening element 5 and a lace-catching element in the form of a lace hook 6. The drawings also show a flexible piece of material 7, to which the lacing device 1 is adapted to be attached.

[0015] The outer fastening element 5 in the lace holding part 2 is provided with external threads 8 and, for the purpose of being tightened and loosened, also at least one recess 9 for a screw tool. The lace hook 6 in the lace holding part 2 has a hook part 10, a fastening hole 11 for fastening the outer fastening element 5 from the outside, and a depression 12 which is formed to enclose and position to the hook part 10 of the lace hook 6. Positioning can take place by means of supplementary non-round or regularly polygonal shapes of the depression 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com