Ejector refrigerant cycle device and control method thereof

a technology of ejector and refrigerant cycle, which is applied in the direction of refrigeration components, machine operation modes, lighting and heating apparatus, etc., can solve the problems of increasing the size of the evaporator and increasing the cost, and the size and cost of the whole ejector refrigerant cycle device is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

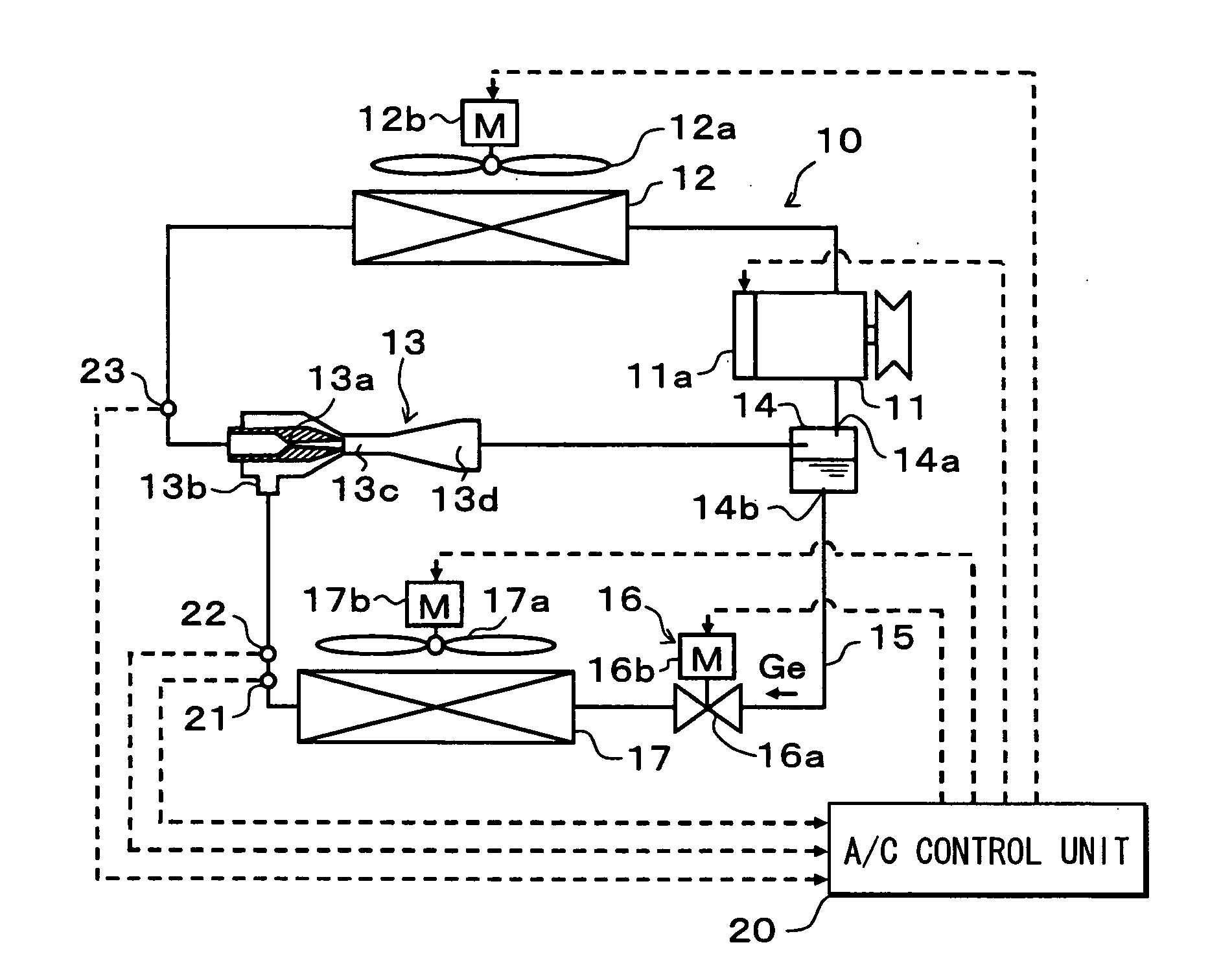

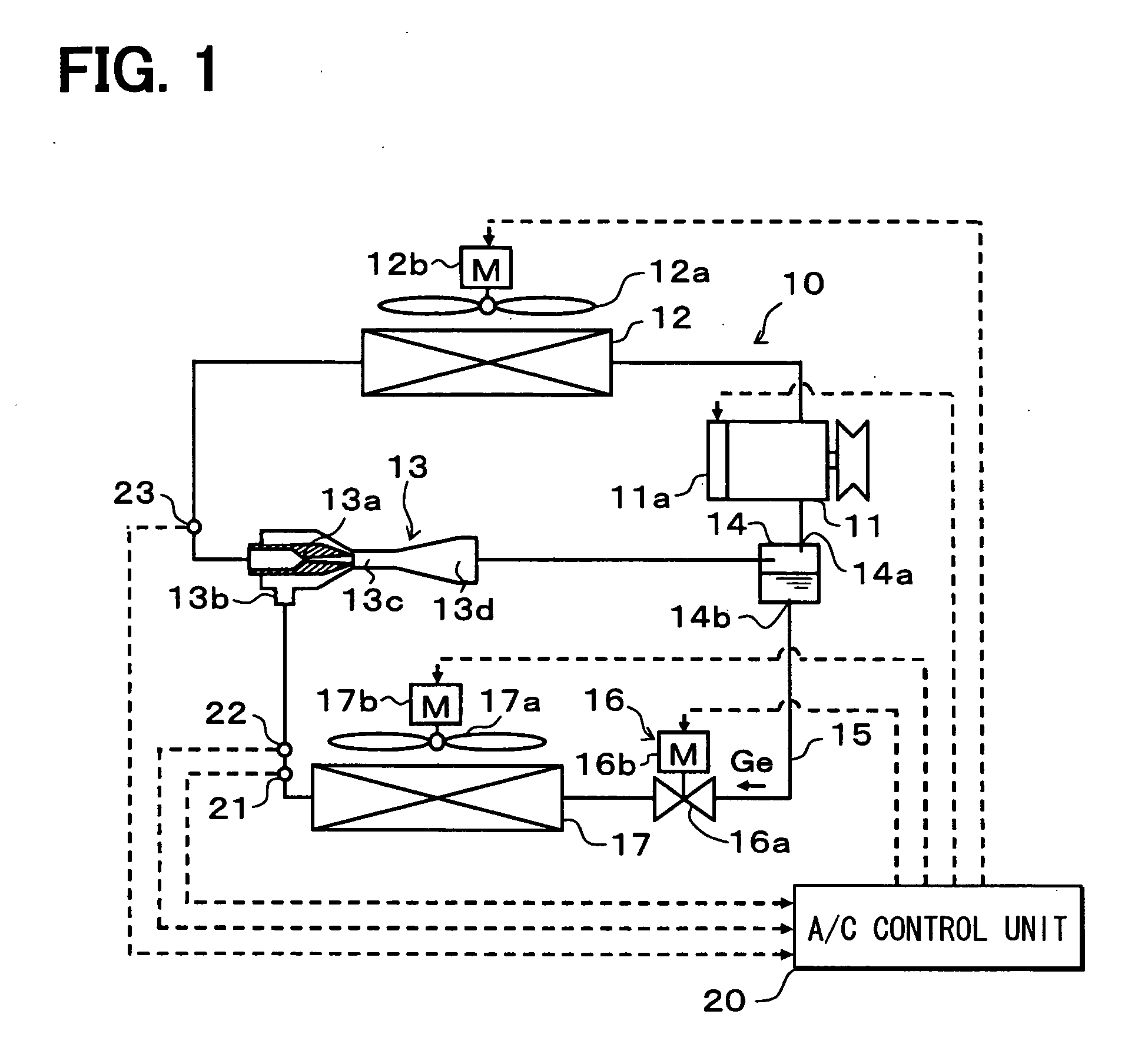

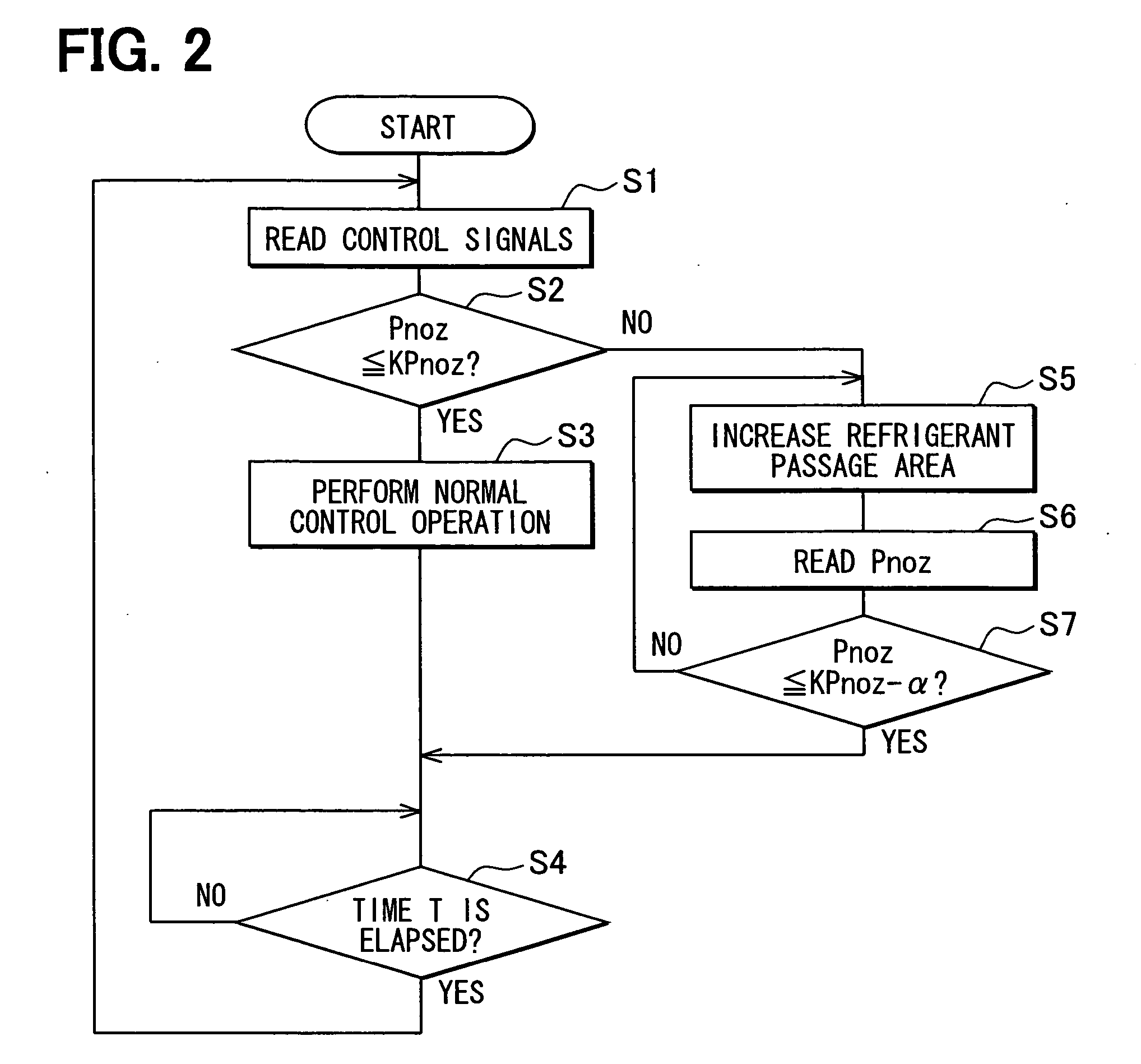

[0026] In this embodiment, refrigerant (e.g., carbon dioxide) in which a high-pressure side refrigerant pressure is higher than a supercritical pressure is used as the refrigerant of an ejector refrigerant cycle device. Thus, the ejector refrigerant cycle device of this embodiment constructs a supercritical refrigerant cycle.

[0027] First, in an ejector refrigerant cycle device 10, a compressor 11 draws, compresses and discharges refrigerant, and increases the pressure of refrigerant to a supercritical pressure in this embodiment. This compressor 11 has a driving force transmitted thereto from a vehicle running engine (not shown) via a pulley and a belt, thereby being rotated and driven. Moreover, in this embodiment, a well-known swash-plate type variable displacement compressor capable of controlling a discharge volume variably and continuously by a control signal from the outside is used as the compressor 11.

[0028] Here, the discharge volume means the geometric volume of an opera...

second embodiment

[0071] In the above-described first embodiment, refrigerant cycle is provided with the liquid-phase refrigerant passage 15 for connecting the liquid-phase refrigerant outlet 14b of the accumulator 14 to the refrigerant suction port 13b of the ejector 13, and the variable throttle mechanism 16 and the evaporator 17 are arranged in this liquid-phase refrigerant passage 15. In the second embodiment, however, as shown in FIG. 3, the liquid-phase refrigerant passage 15 is not provided but there is provided a branch passage 25 for branching the refrigerant flow at a branch point Z that is positioned between the downstream side of the radiator 12 and the upstream side of the nozzle portion 13a of the ejector 13.

[0072] This branch passage 25 is a refrigerant passage for connecting the branch point Z to the refrigerant suction port 13b of the ejector 13. In this embodiment, the variable throttle mechanism 16 is arranged in the branch passage 25, and the evaporator 17 is arranged on the down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com