Power push pole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

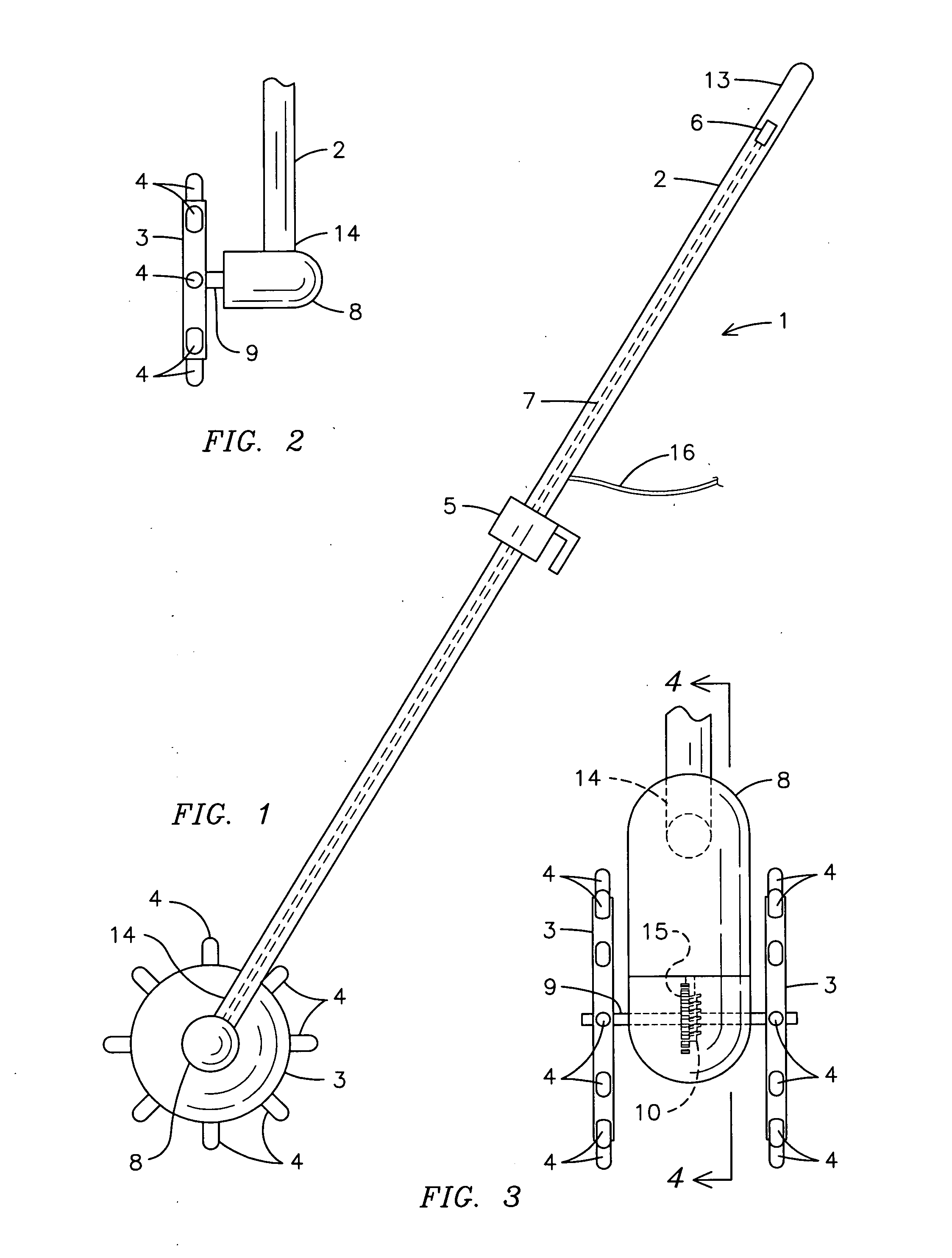

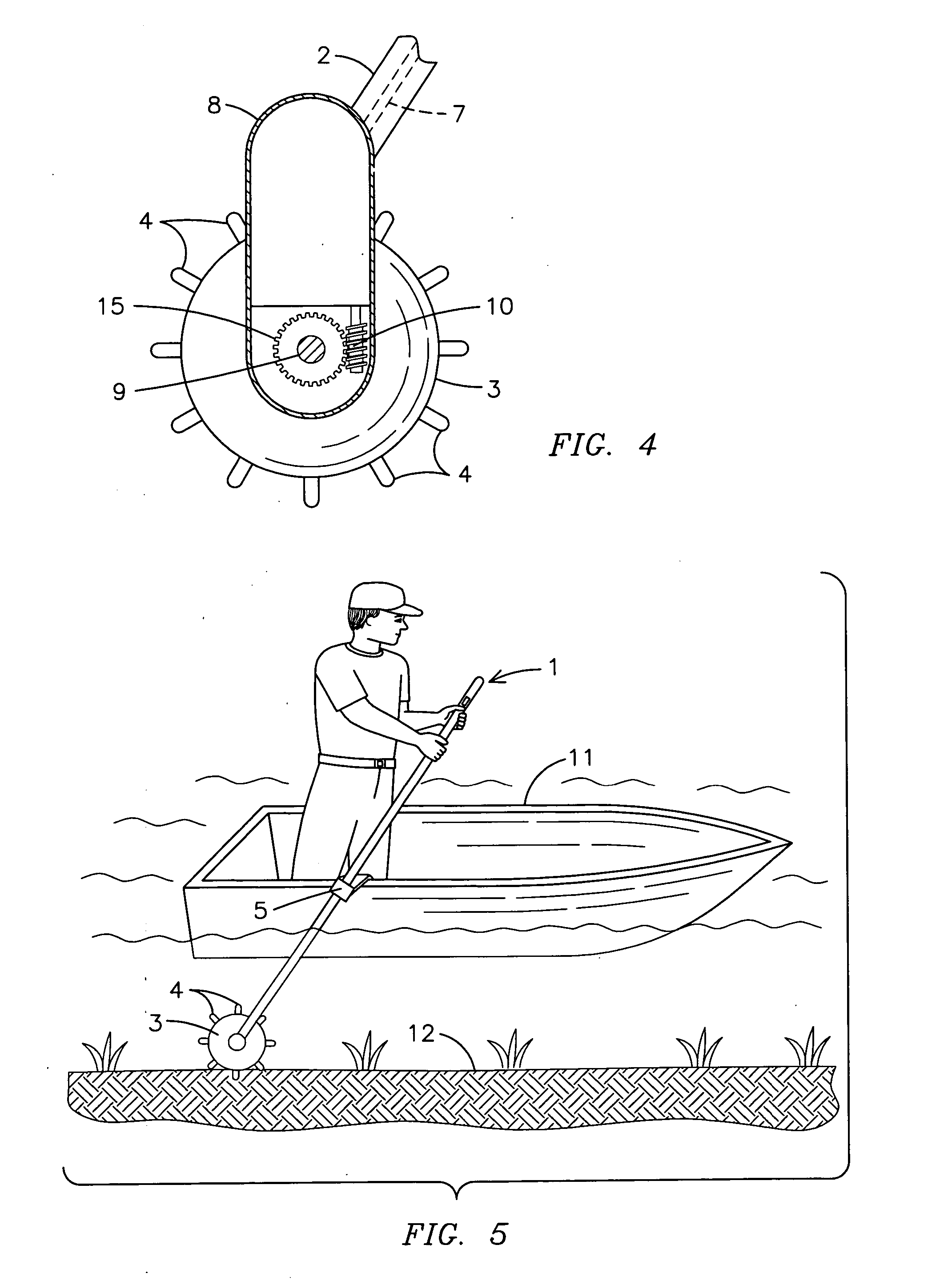

[0040] With reference to FIG. 1, a plan view of the power push pole of the present invention is shown. The power push pole 1 comprises an elongated handle 2 having a proximal end 13 and a distal end 14, a motor 8 secured to the distal end 14 of the handle and at least one drive wheel 3 is secured to the motor 8. The drive wheel 3 includes a plurality of extending members 4 which radiate from the drive wheel 3, such as spikes. A wire 7 connects the motor 8 to a control 6 located on the handle 2. The control 2 permits a user to turn the power push pole 1 on and off. In addition, the control 2 may provide for varying predetermined speeds, such as slow, medium and fast, and varying predetermined directions, such as forward and reverse, of the drive wheel 3. An optional fastening means, such as a bracket 5, may be attached to the handle 2 so as to permit a user to secure the power push pole 1 to the side of a vessel or stern or polling platform.

[0041]FIG. 2 shows a front view of a drive ...

second embodiment

[0043]FIG. 4 shows a cross-sectional view of the motor 8 section of the present invention along line 4-4 of FIG. 3. The horizontal shaft 9 runs through the center of the cog wheel 15. The cog wheel 15, in turn, is located adjacent to and in operation with the worm gear 10. When a user turns on the power push pole 1 via the control 6, an electrical signal powered by a power source, preferably a 12 Volt / 24 Volt battery, is sent to the control 6 via wiring to the power source 16. The wire 7 from the control 6 then transmits power to the motor 8 to power the drive wheels 3. The motor 8 is sealed and covered, preferably with oil to protect the worm gear 10.

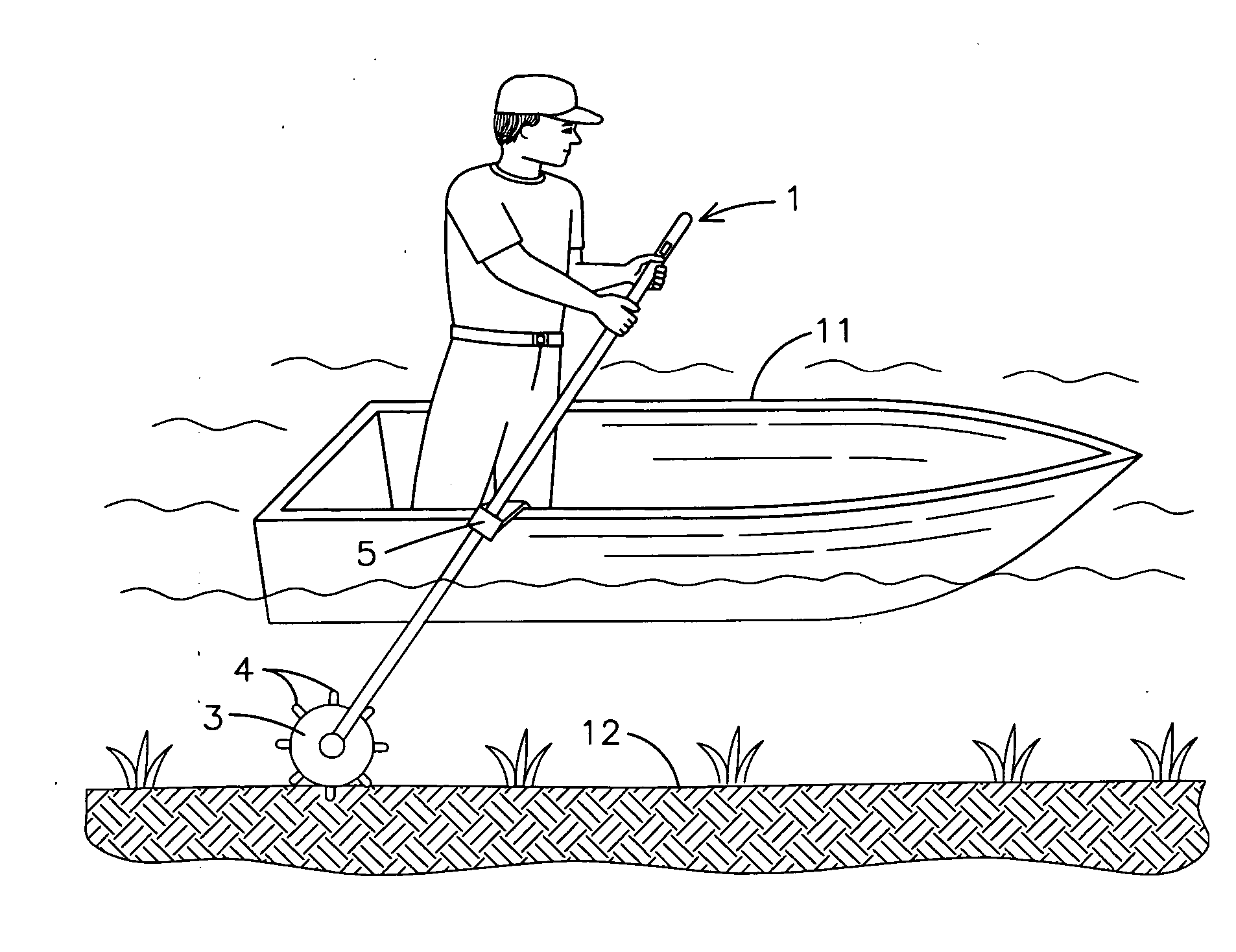

[0044] Finally, FIG. 5 shows a perspective view of the power push pole of the present invention in use. An optional bracket 5 may be secured to the transom or poling platform of a boat 11 so as to permit an individual to more easily maneuver the power push pole 1. Interchangeable extending members 4, such as spikes, and / or drive wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com