Bedding system with replaceable comfort layer

a comfort layer and bed frame technology, applied in the field of mattress and spring combination, can solve the problems of not being the first choice or most comfortable bed in a particular room, the particular comfort layer might not be to the user's liking, and the price of replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

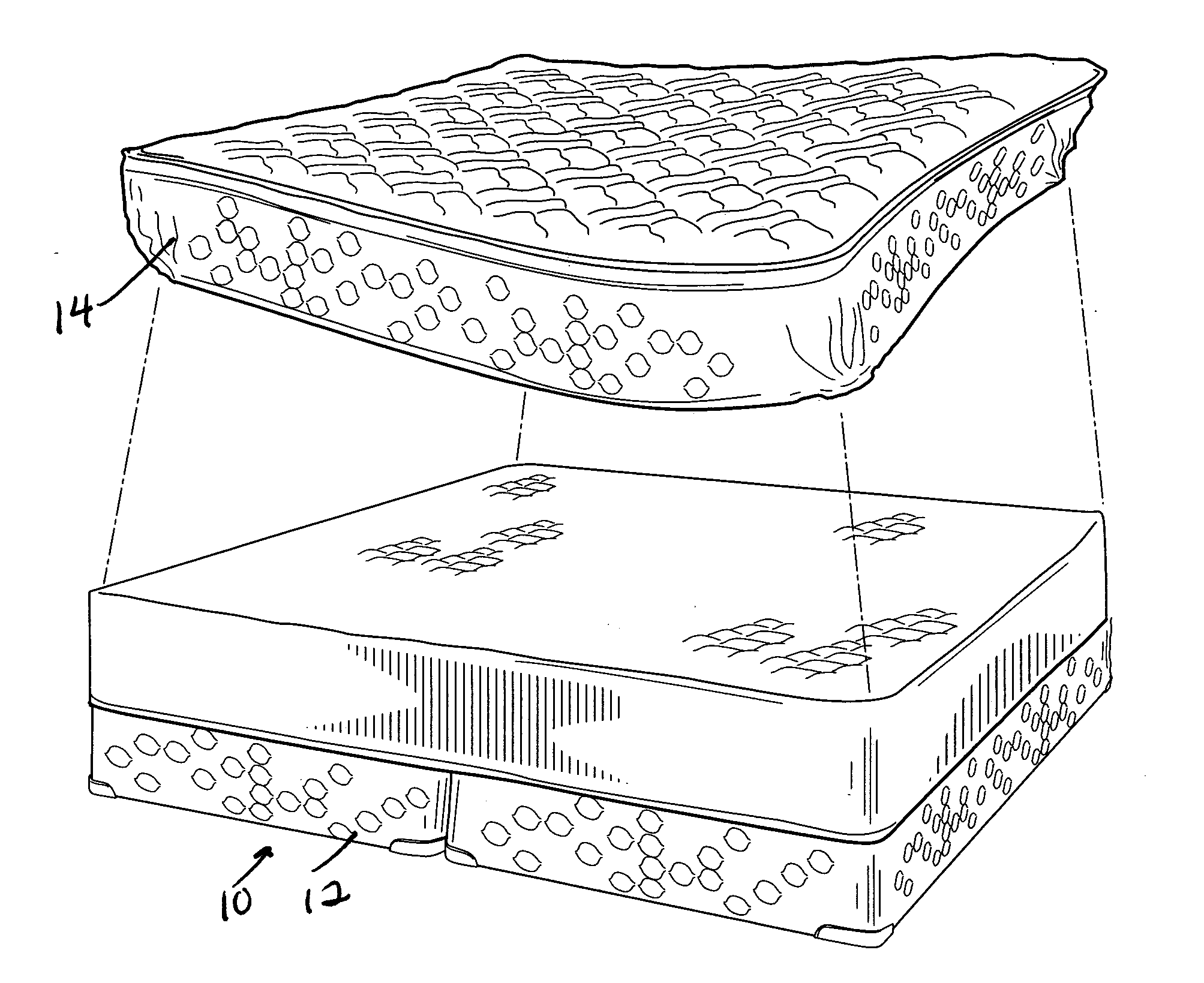

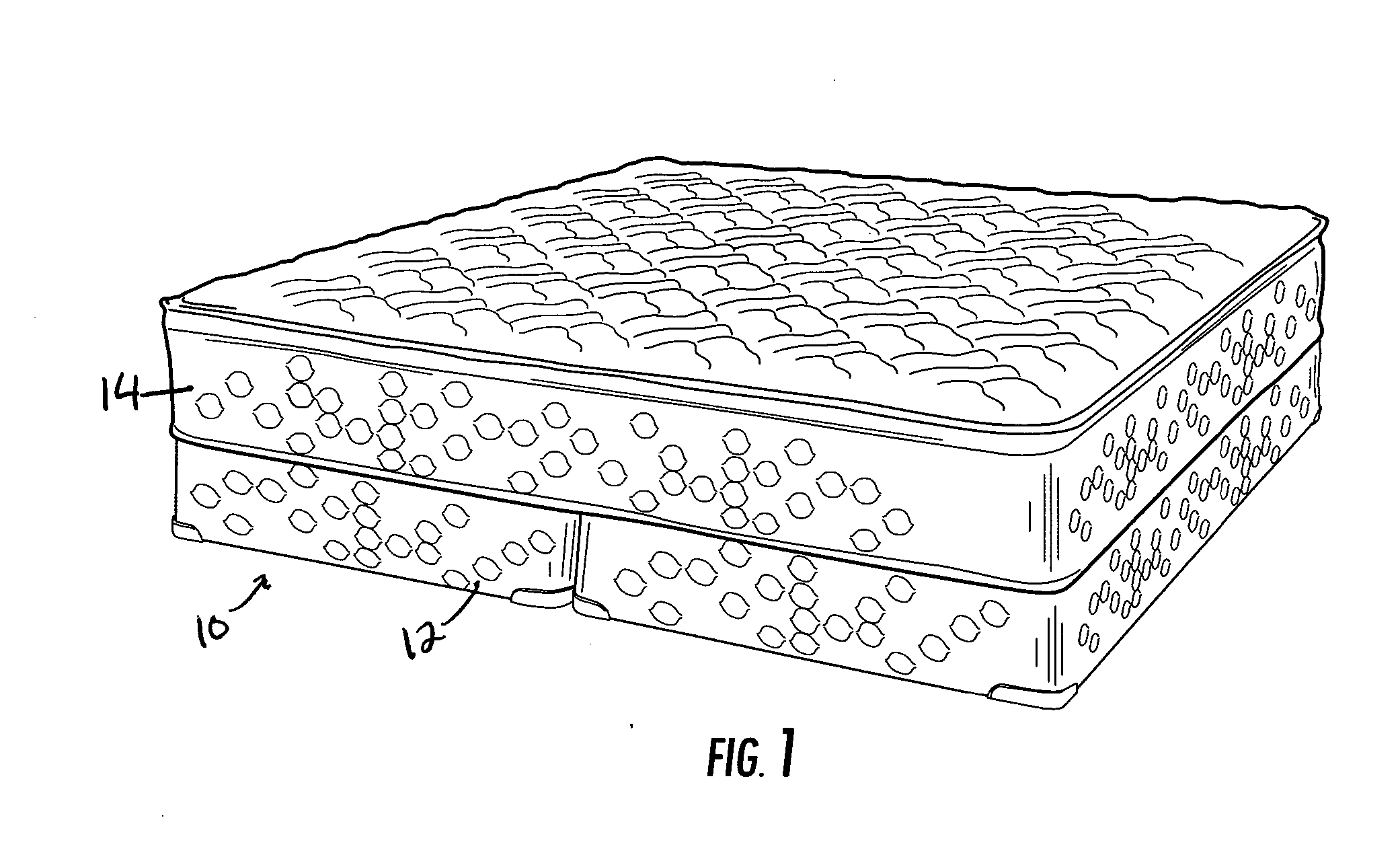

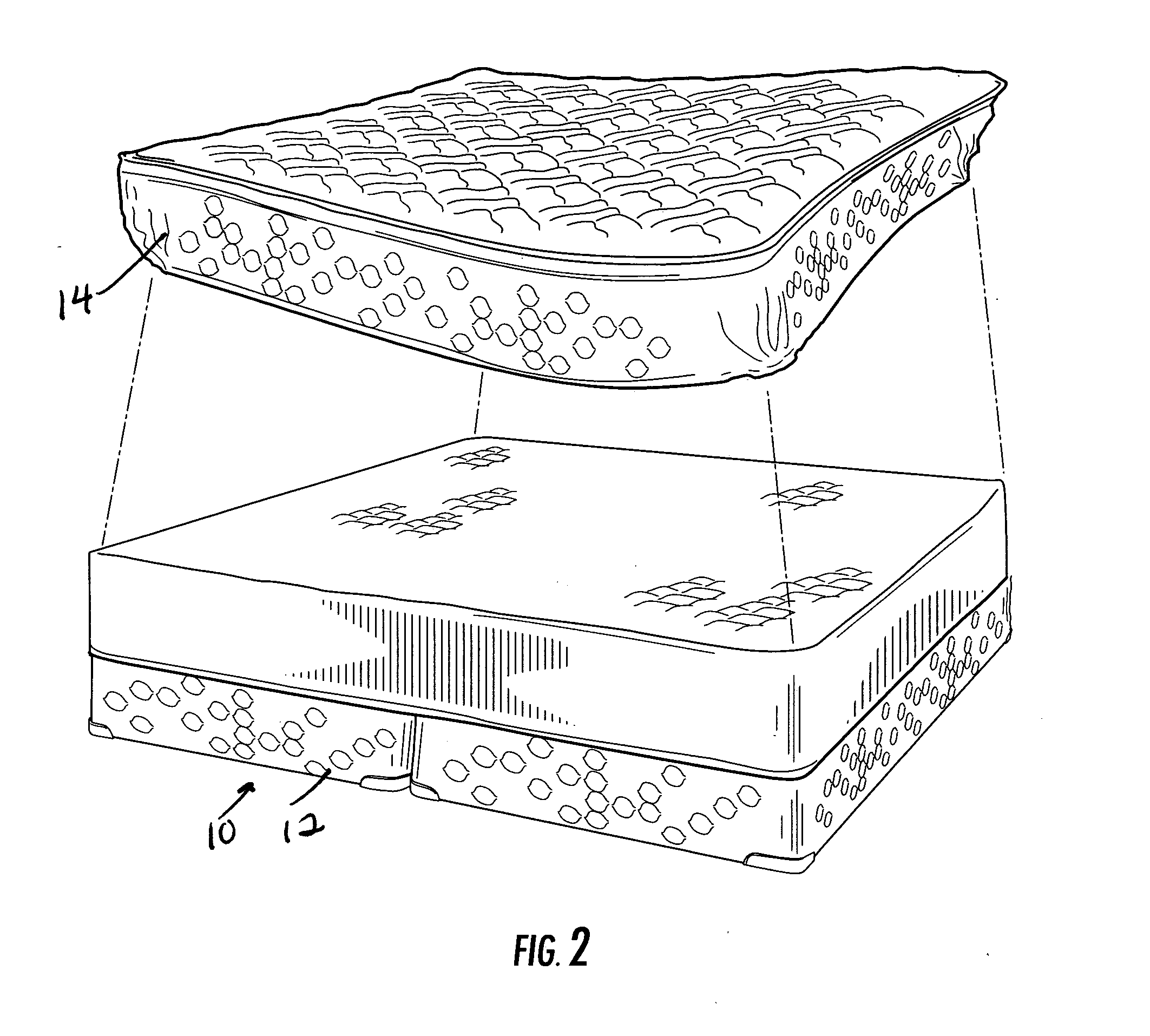

[0008] Referring now to the drawings, a preferred embodiment of the invention is shown generally at 10, and includes a conventional box spring 12 and a novel support / comfort layer assembly 14. Referring now to FIGS. 2-3, support / comfort layer assembly 14 includes a support base 16 and a separate comfort layer 18, both of which are encased in a removable cover 20. The assembly rests atop the box spring according to conventional practice. However, in the present invention the comfort layer 18 can be readily removed and replaced by simply removing cover 20 and disengaging several hook and loop or other fasteners, exposing the comfort layer 18. This feature enables the matching of a desired comfort layer 18 on any bed assembly made according to the invention. For example, a hotel could replace a worn comfort layer and cover without the need to replace the support base and box spring, saving a significant expense since the comfort layer represents a relatively modest cost compared to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com