Feeder for punch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

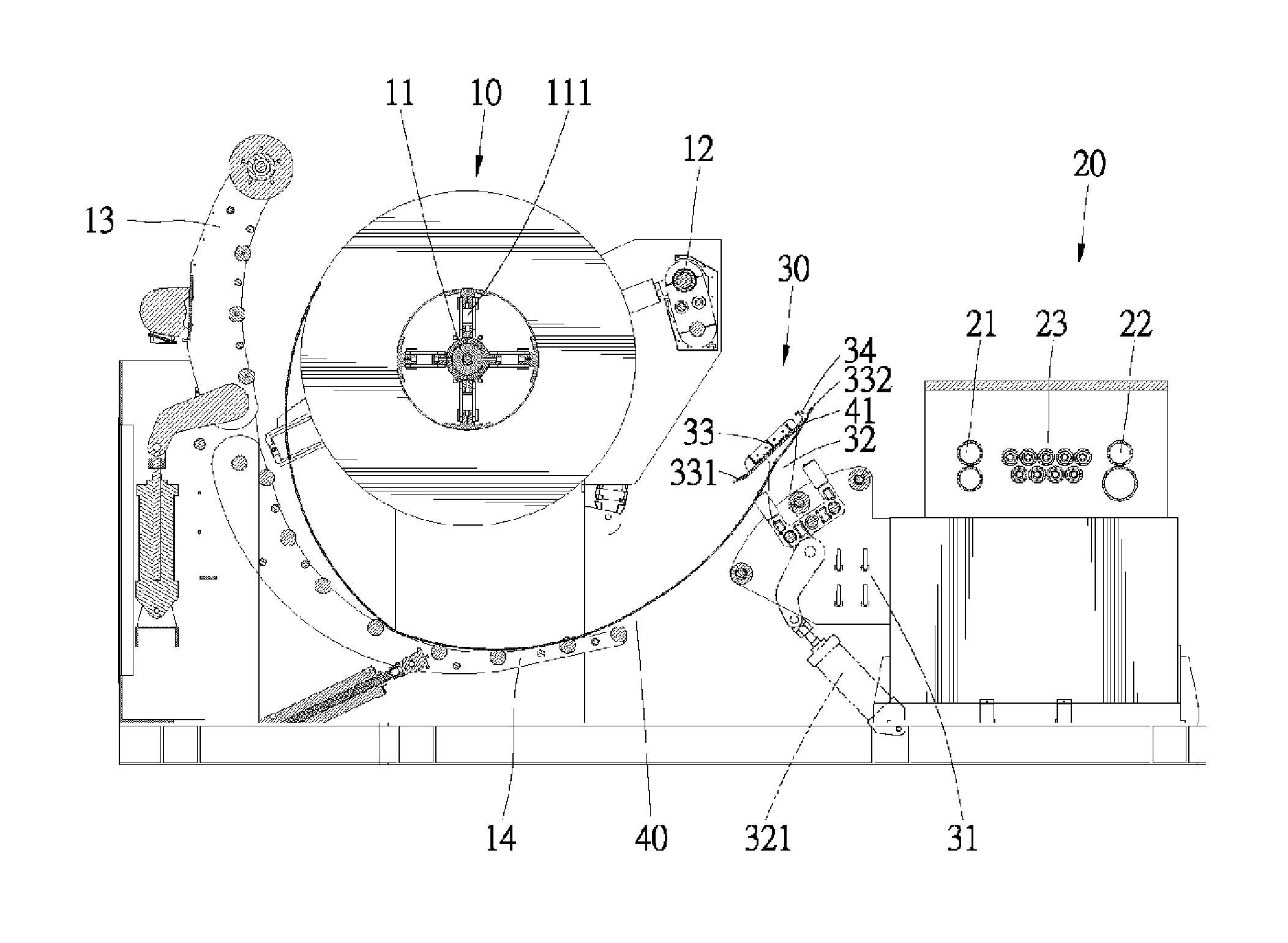

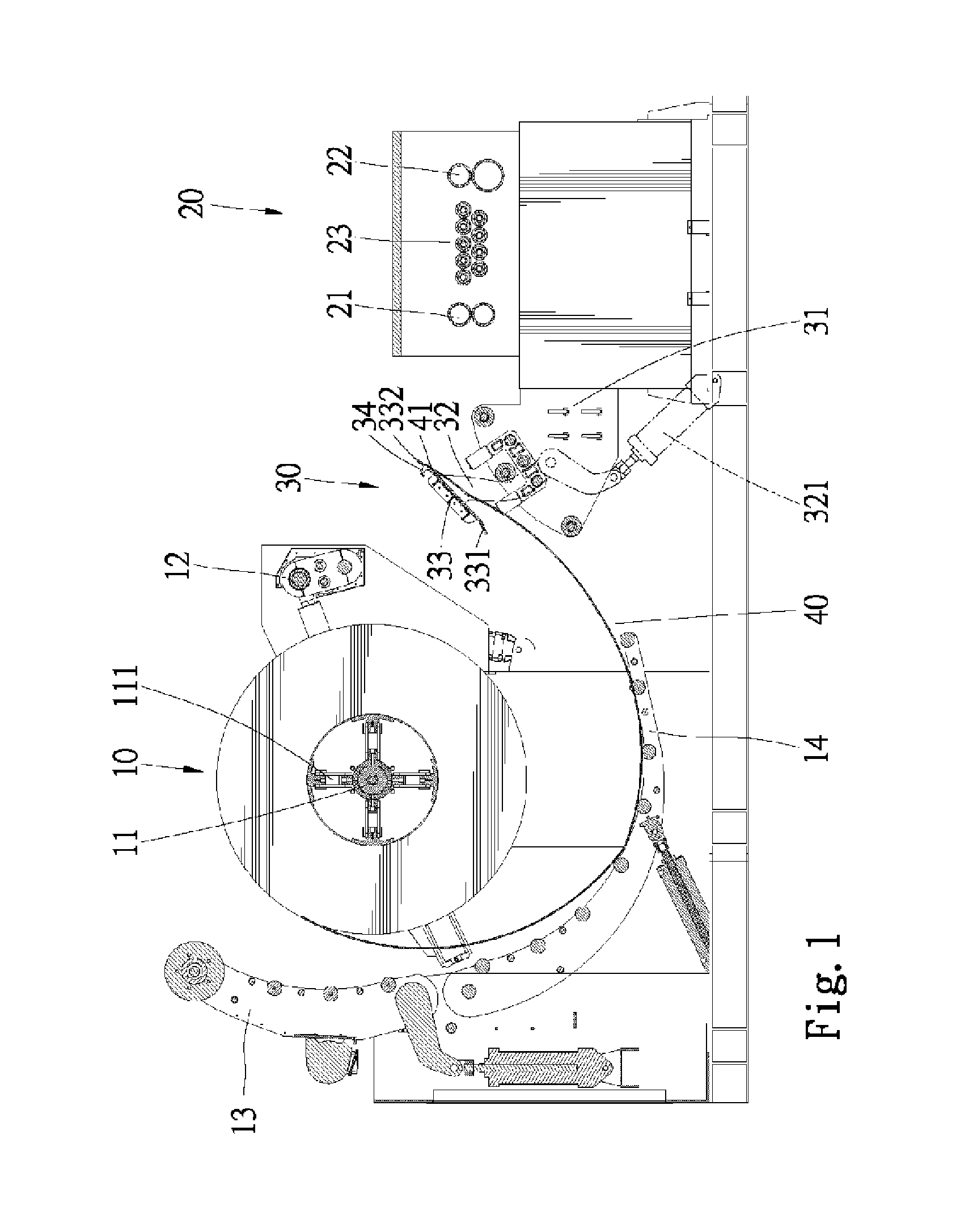

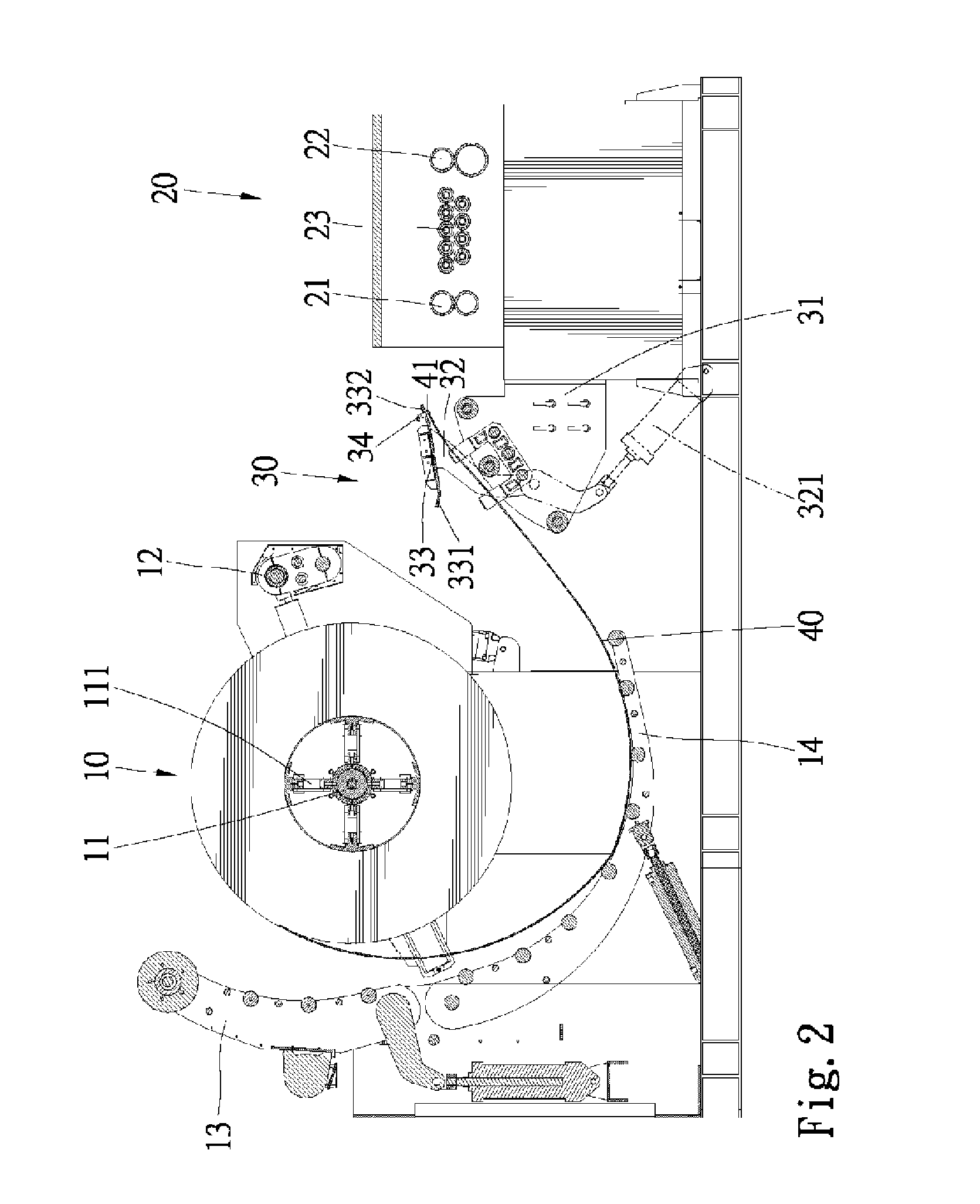

[0018] Referring to FIGS. 1 through 4, there is shown a feeder for a punch according to the preferred embodiment of the present invention. The feeder includes a feeding unit 10, a bending unit 30 and a transferring unit 20. A metal strip 40 is rolled. The roll of the metal strip 40 is installed on the feeding unit 10. The feeding unit 10 rotates the roll so as to feed the metal strip 40. On reaching the bending unit 30, a leading edge 41 of the metal strip 40 travels at a large curvature. The bending unit 30 pivots so as to bend the metal strip 40. When leaving the bending unit 30, the leading edge 41 of the metal strip 40 travels at a small opposite curvature. The bending unit 30 guides the metal strip 40 to the transferring unit 20. The transferring unit 20 transfers the metal strip 40 to another unit of the punch.

[0019] The feeding unit 10 includes a shaft 11 for rotation and a plurality of spoke-liked extenders 111 extensible from the shaft 11 to the roll of the metal strip 40....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com