Novel surface structures and methods thereof

a surface structure and technology of a new type of structure, applied in the direction of protective foundations, construction, foundation engineering, etc., can solve the problems of reducing the effect of excavation and site manipulation, limiting environmental impacts on surface and subsurface water flows, soil biological functions, etc., to preserve structural integrity, biological life, moisture conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

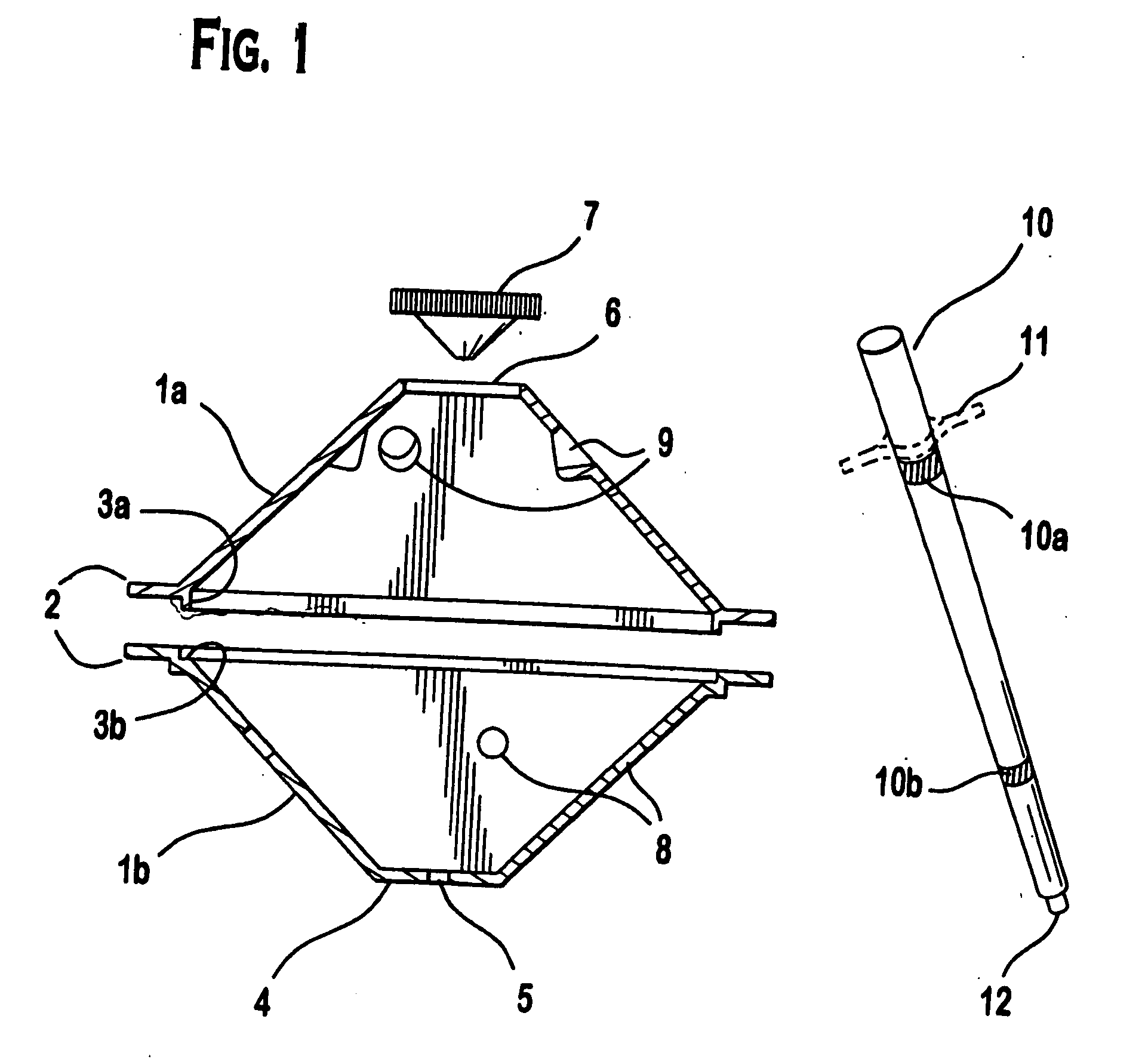

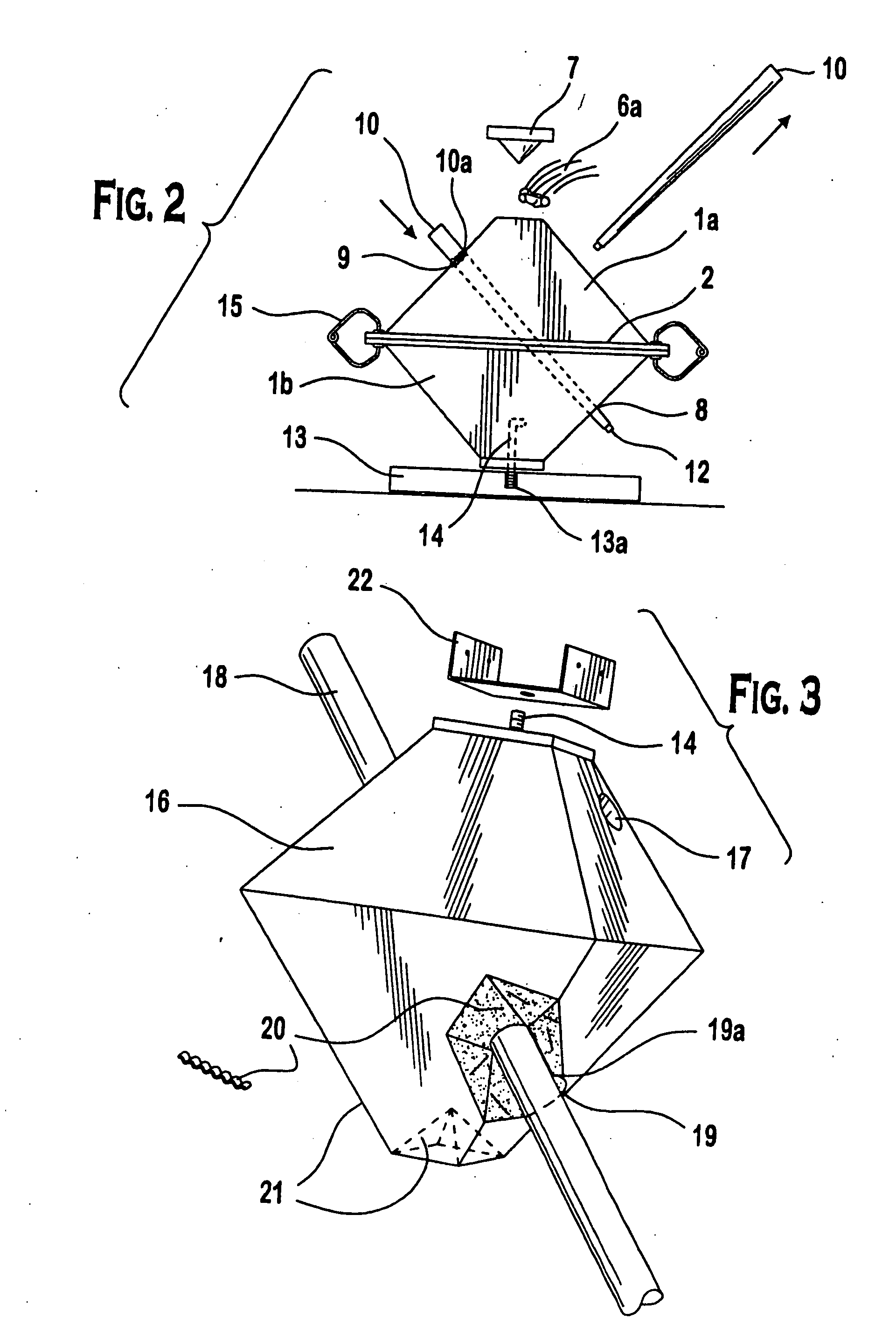

[0026] Referring now to FIG. 1, views of the primary components used in the inventive process to create the first embodiment are shown. There is a section view of a two part thermoplastic form 1a. and 1b, with side flanges 2 including a flange male and female interlock 3a and 3b. The form 1b. has a square shaped top 4, though this could be of any desired geometry, circular, rectangular, triangular, with a centered hole 5 for the placement of an embedded anchor bolt (see component 14, FIGS. 2 and 3). The form 1a. has an open end 6 for receiving a poured, curable cementious medium, and the subsequent placement of a pyramidal shaped plug 7. The use of this plug 7 will be more fully described in FIGS. 2 and 3, and in the example description. The main walls of the forms la. and 1b. are angled at approximately 45 degrees relative to the side flanges 2 and / or the top square plane 4. These sides contain round holes 8 in form 1b, and opposing, corresponding dimpled round holes 9 in form 1a. ...

second embodiment

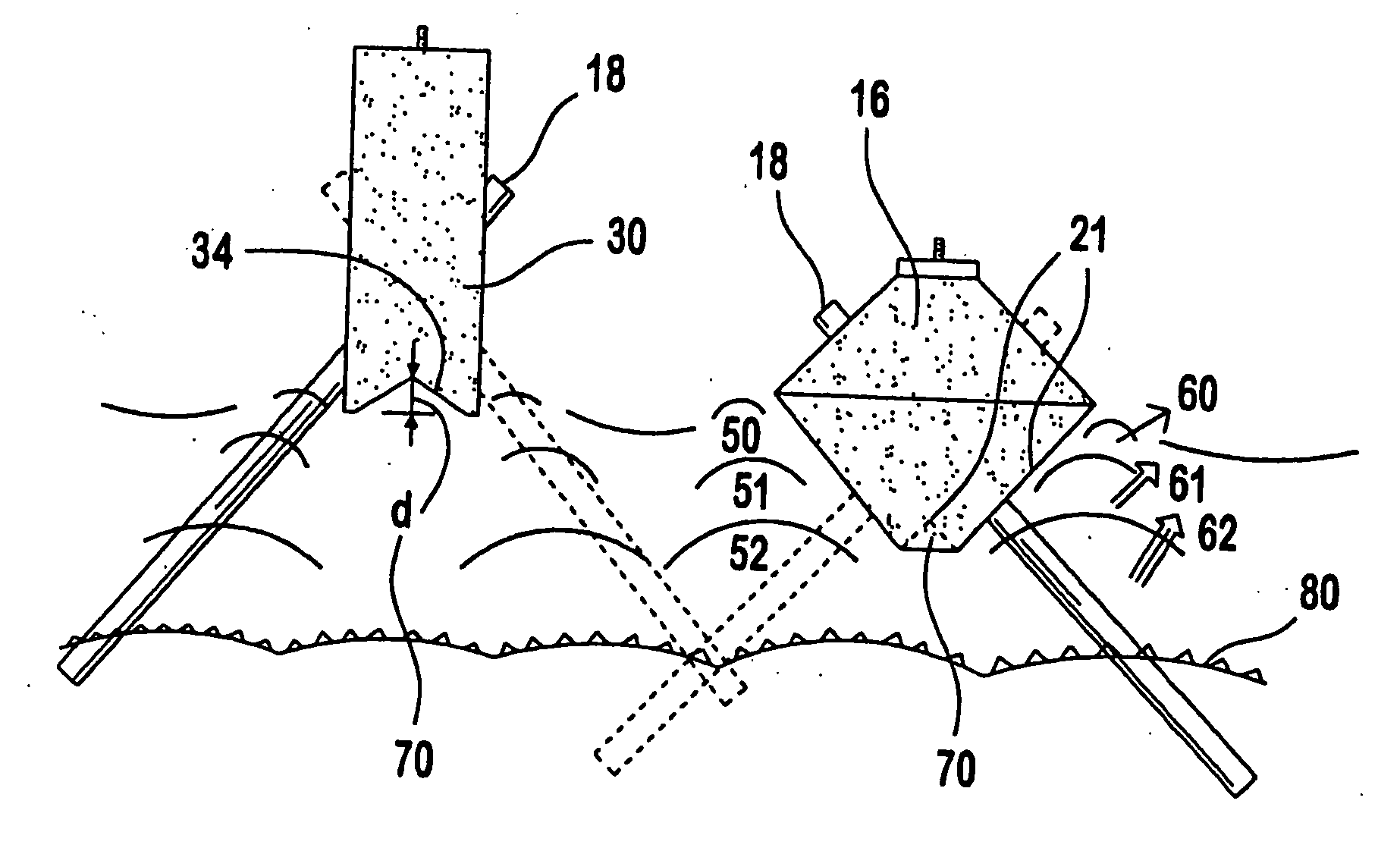

[0040]FIG. 4 is a variation on the first embodiment, creating a more rectilinear shaped structural body 30, which may be cast as a block to support point loads as in the first embodiment, but is more naturally employed as a continuous or longitudinal section of fixed width and utilizing a series of paired cast cavities along its length. In this application, rather than a top and bottom form, side forms 31a and 31b are employed. They are connected at the top and base by a restricting element 32 preventing the lateral outward movement of the forms under internal side pressures from the cementious pour. These restricting cleats are common in industry and do not represent an inventive step. The wedge block 33 is employed similar to the plug element 7 in FIG. 2. It is continuous along the full length of the forms, and will generate the necessary base shape 34 in the final cast body. The forms have round holes 8 in a section of the form shaped to be perpendicular to the axis of the dowel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com