Cylinder head cover for a cylinder head of an internal combustion engine

a technology of internal combustion engine and cylinder head cover, which is applied in the direction of machine/engine, sealing, lubrication of auxillaries, etc., can solve the problems of increasing the weight of the cylinder head cover, increasing and reducing the sealing tightness, so as to reduce the number of connecting elements and reduce the magnitude of the attachment force. , the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

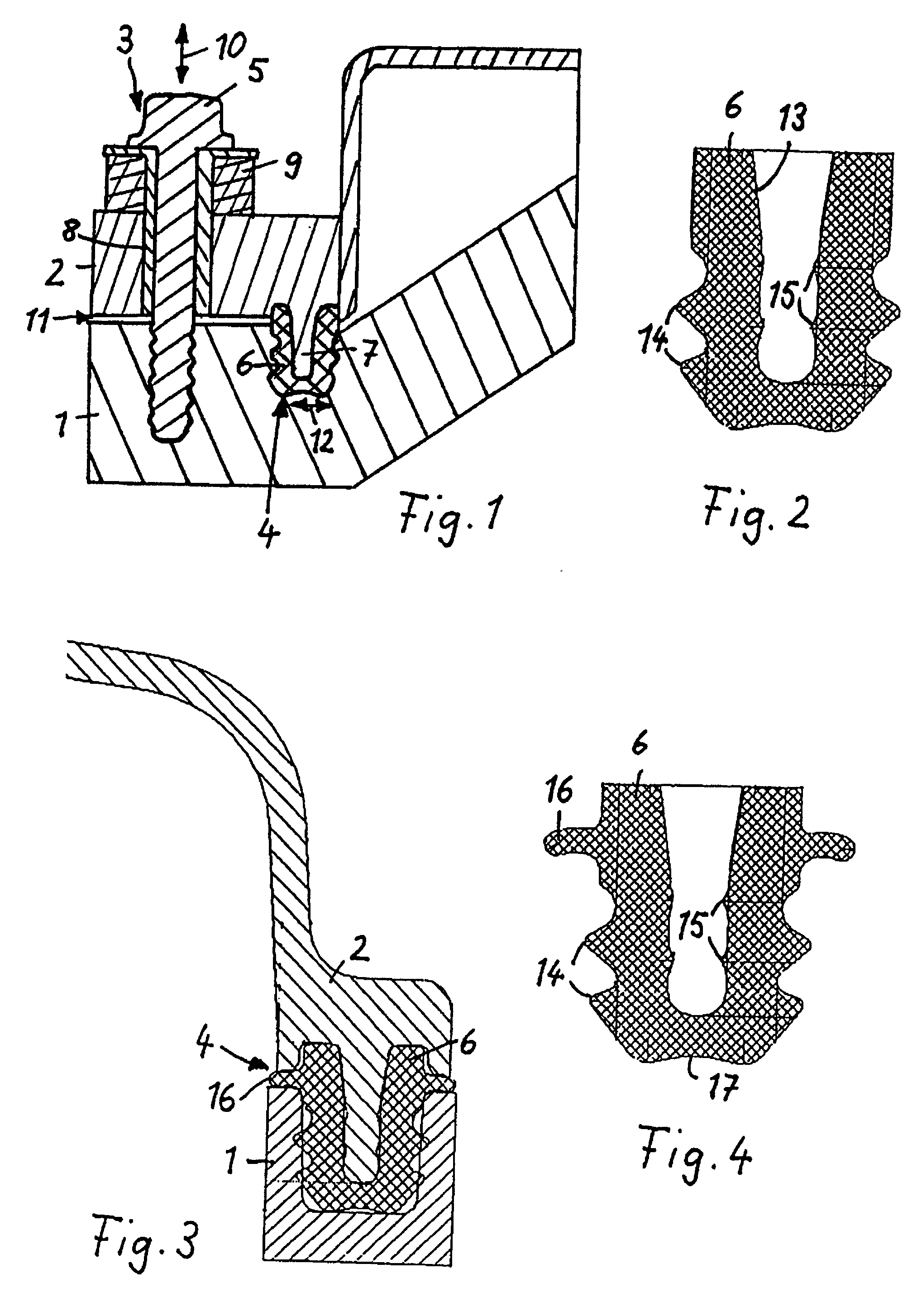

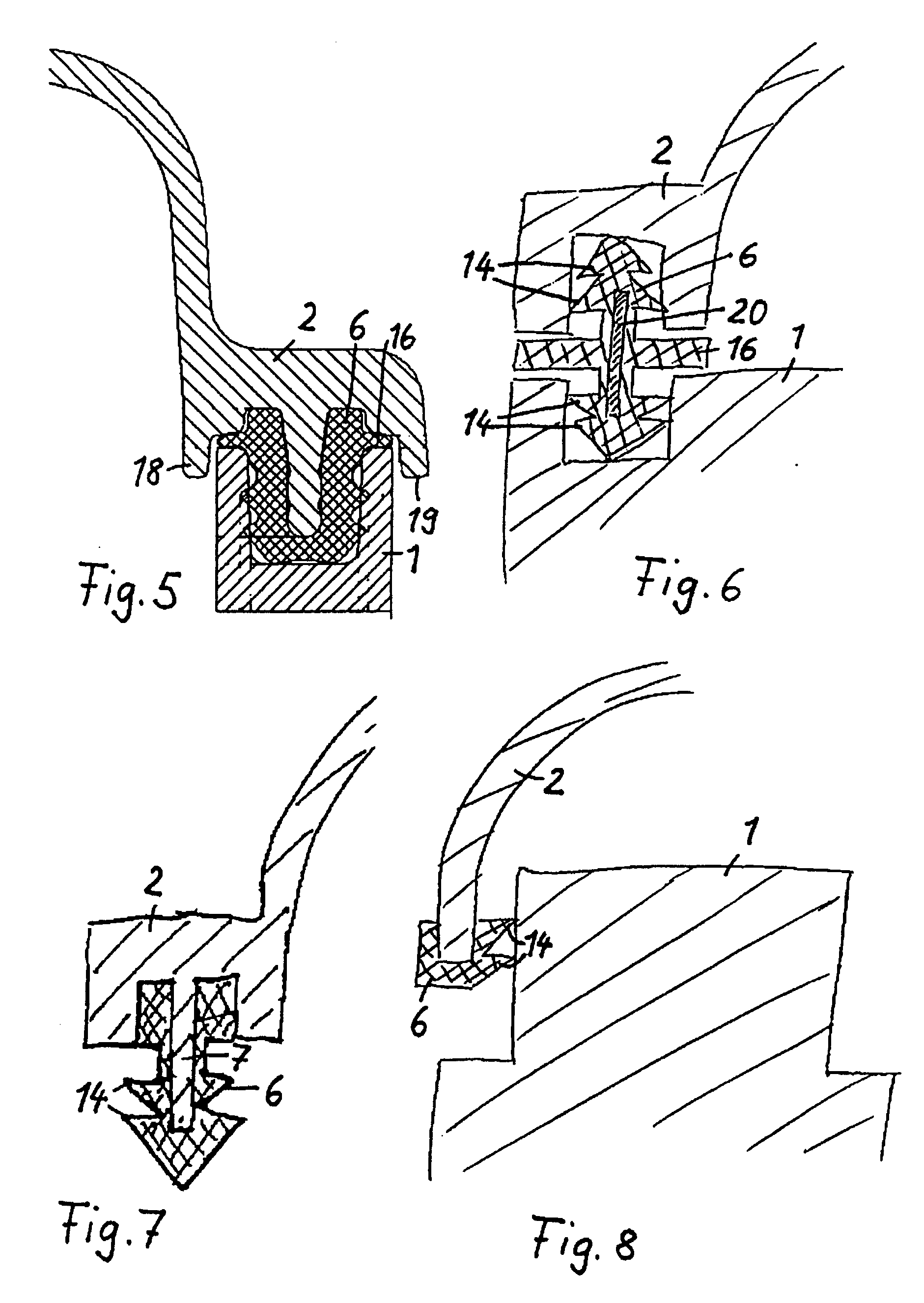

[0029] In the figures, like components are identified by the same reference numerals.

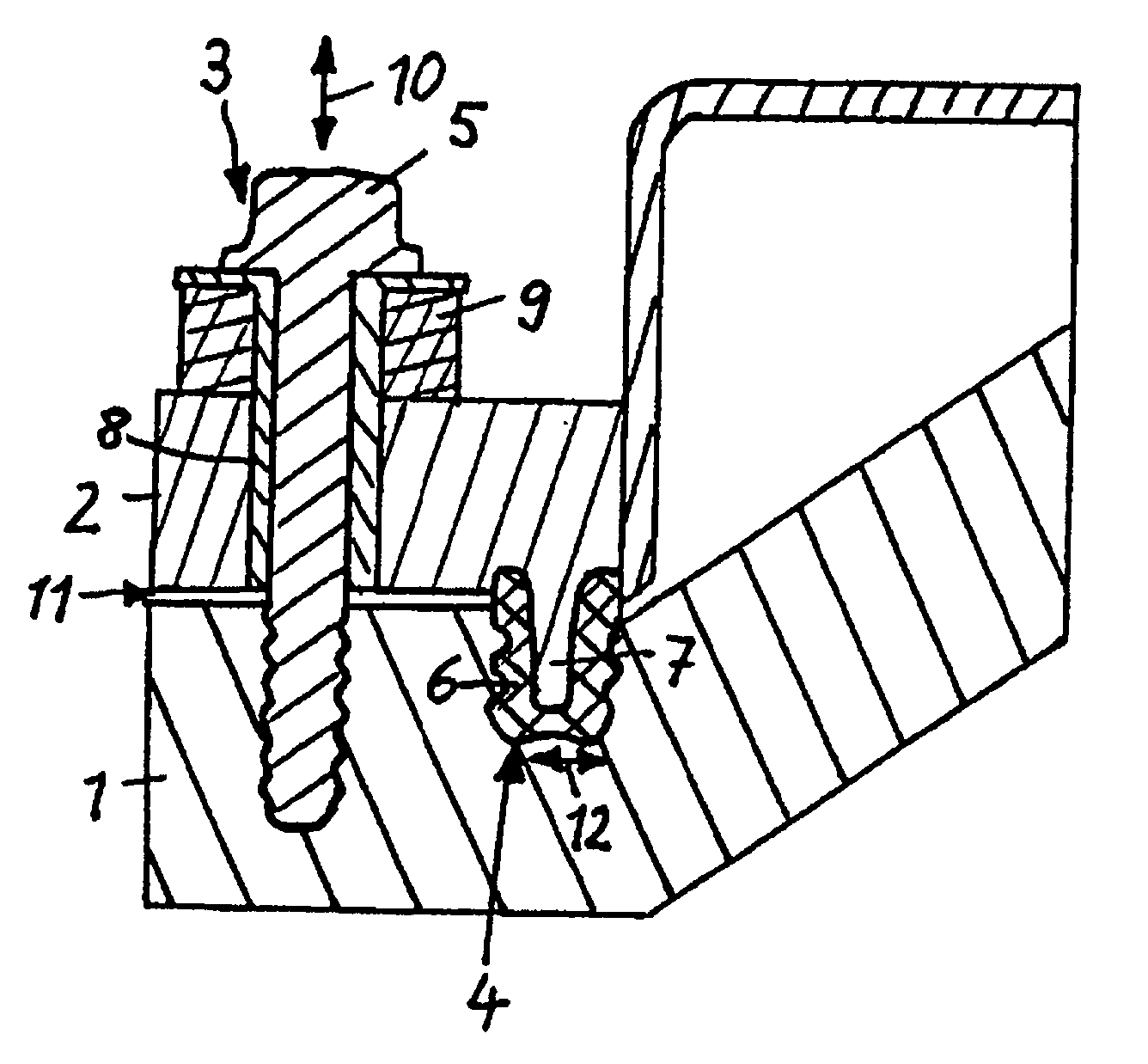

[0030]FIG. 1 shows a cylinder head 1 of an internal combustion engine with mounted cylinder head cover 2, which is held to the cylinder head 1 in an outer connecting region 3. Separate therefrom and offset inwardly is a sealing region 4 between the cylinder head 1 and the cylinder head cover 2, which comprises a circumferential sealing element 6 that is inserted into a peripheral groove formed in the top of the cylinder head. The cross-section of sealing element 6 is cup-shaped, and a support member 7 formed integrally with the cylinder head cover 2 projects into the interior of the sealing element 6. The sealing element 6 is slipped onto the support member 7 to obtain a pre-assembled unit. The sealing element 6 extends all around adjacent the outer margin of the cylinder head cover, providing a circumferential seal between the cylinder head and the cylinder head cover.

[0031] The connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com