Evaporator

a technology of evaporator and evaporator body, which is applied in the direction of indirect heat exchangers, refrigeration components, lighting and heating apparatus, etc., can solve the problems of insufficient draining performance, troublesome assembly of refrigerant flow members and separate fin members, and impairment of heat-exchange performance, so as to improve air flow resistance, improve cooling performance, and enhance the effect of condensed water draining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

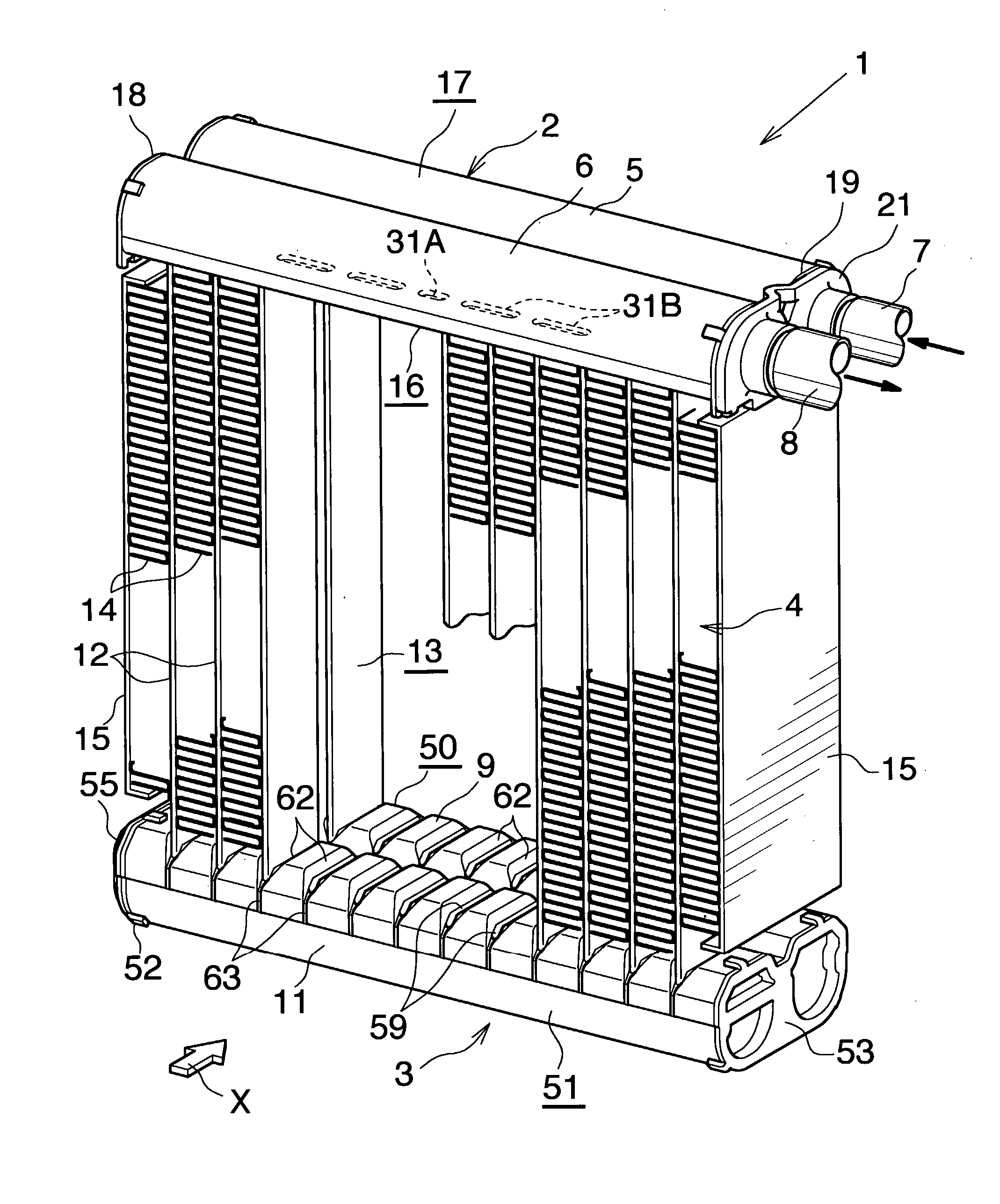

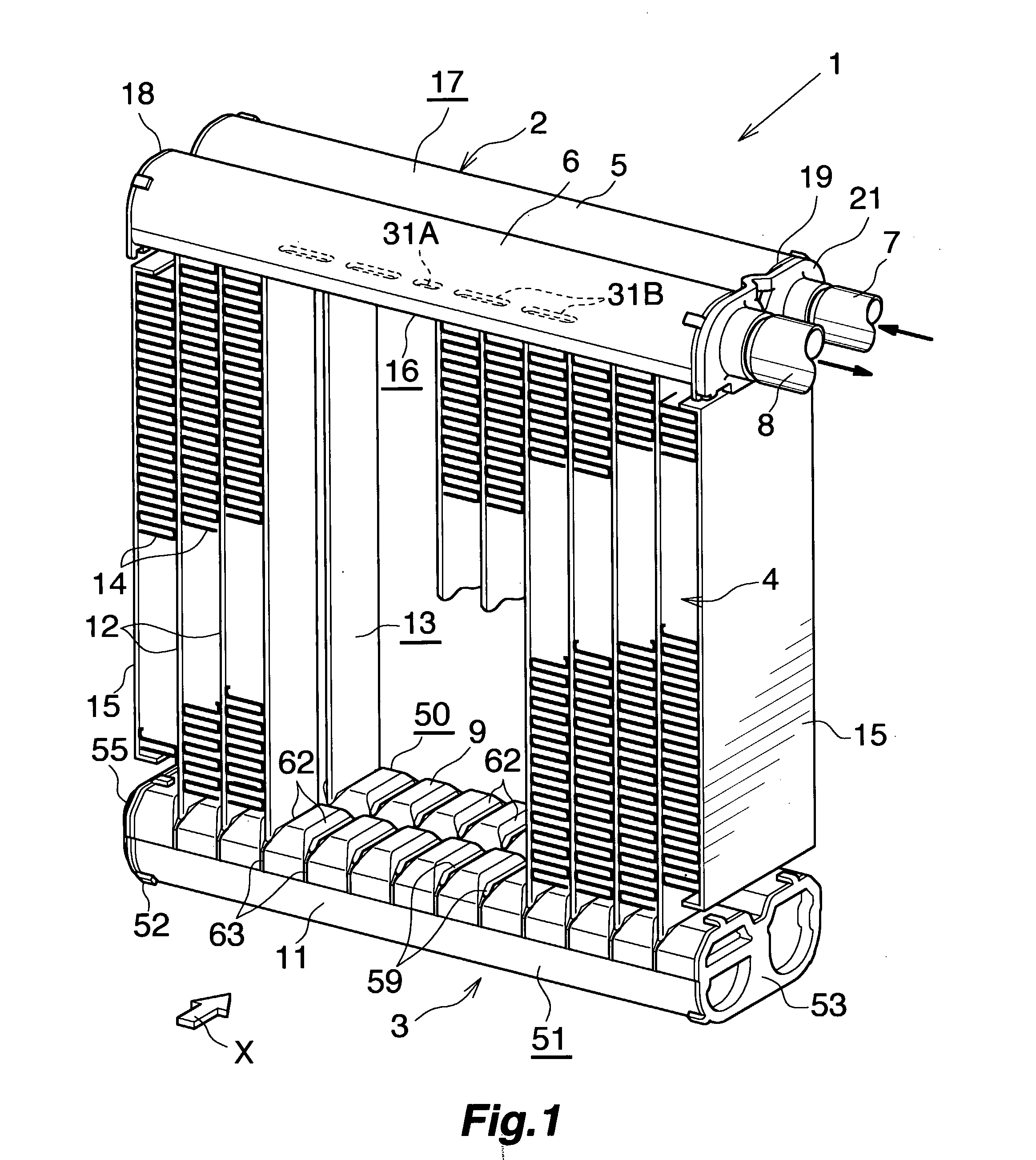

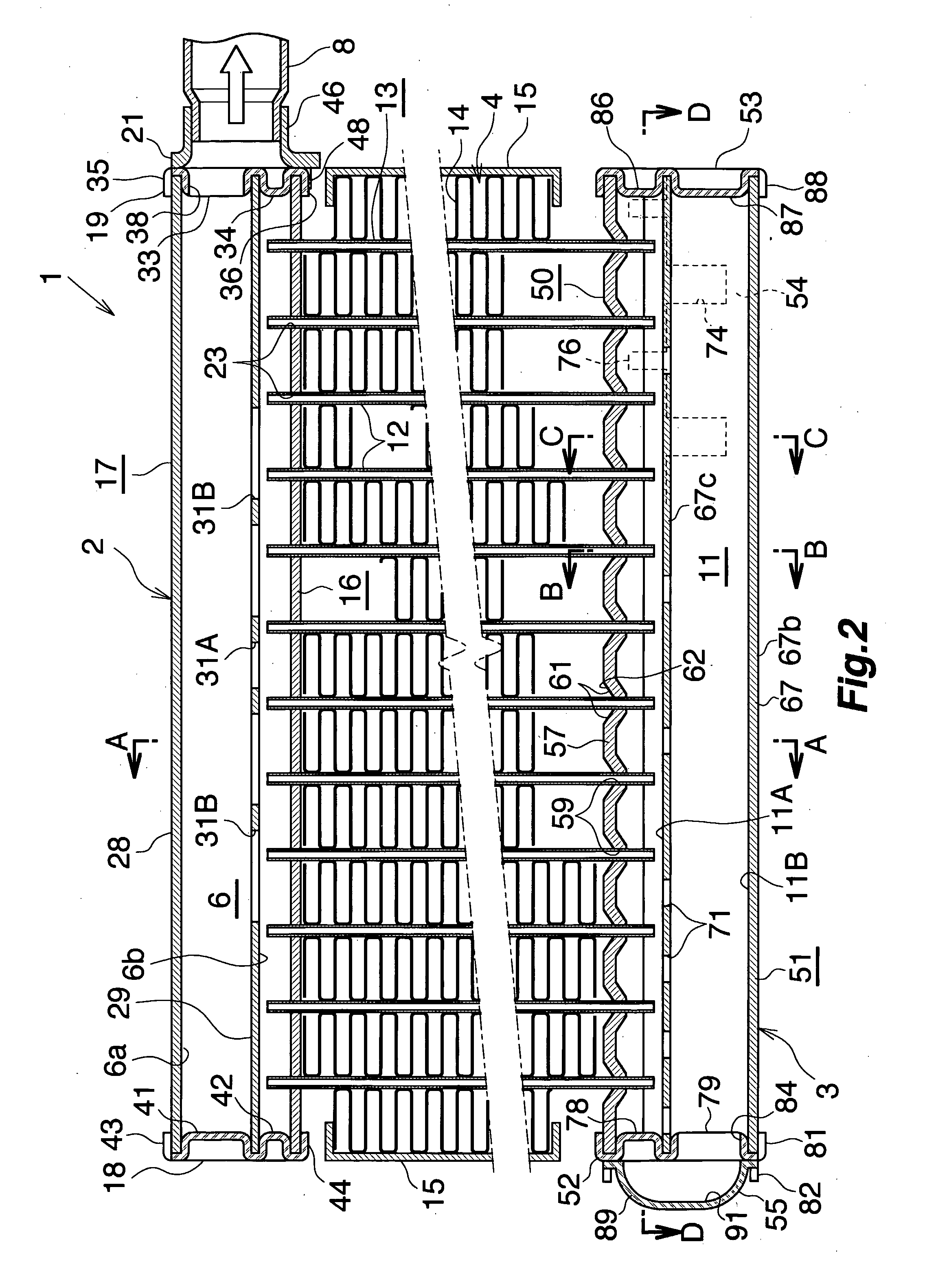

[0047] The present embodiment is illustrated in FIGS. 1 to 10.

[0048] FIGS. 1 to 3 show the overall configuration of an evaporator, and FIGS. 4 to 10 show the configuration of essential portions of the evaporator. FIG. 11 shows how a refrigerant flows in the evaporator.

[0049] In FIGS. 1 to 3, the evaporator (1), which is used in a car air conditioner using a chlorofluorocarbon-based refrigerant, includes a refrigerant inlet / outlet tank (2) made of aluminum and a refrigerant turn tank (3) made of aluminum, the tanks (2) and (3) being vertically spaced apart from each other, and further includes a heat exchange core section (4) provided between the tanks (2) and (3).

[0050] The refrigerant inlet / outlet tank (2) includes a refrigerant inlet header section (5) located on a side toward the front (downstream side with respect to the air flow direction) and a refrigerant outlet header section (6) located on a side toward the rear (upstream side with respect to the air flow direction). A r...

embodiment 2

[0093] The present embodiment is illustrated in FIG. 12.

[0094] In the corrugate fins (14) of the evaporator of Embodiment 2, in addition to the cutouts (95) and the inward projections (96) provided at positions corresponding to clearances between the adjacent front and rear flat tubes (12), the cutouts (95) and the inward projections (96) are formed at front projecting portions (140) of the corrugate fins (14) projecting frontward beyond the front ends of the front flat tubes (12).

[0095] Other configurational features are similar to those of the evaporator (1) of Embodiment 1.

[0096] In the evaporator of Embodiment 2, when condensed water is generated on the surface of the corrugate fins (14), a portion of the condensed water flows downward through openings between the louvers (94). Also, the condensed water flows, by the effect of surface tension, toward joint portions between the flat tubes (12) and the wave crest portions (14a) and the wave trough portions (14b) of the corrugat...

embodiment 3

[0097] The present embodiment is illustrated in FIG. 13.

[0098] In the corrugate fins (14) of the evaporator of Embodiment 3, in place to the cutouts (95) and the inward projections (96) provided at positions corresponding to clearances between the adjacent front and rear flat tubes (12), the cutouts (95) and the inward projections (96) are formed at the front projecting portions (140) of the corrugate fins (14) projecting frontward beyond the front ends of the front flat tubes (12).

[0099] Other configurational features are similar to those of the evaporator (1) of Embodiment 1.

[0100] In the evaporator of Embodiment 3, when condensed water is generated on the surface of the corrugate fins (14), a portion of the condensed water flows downward through openings between the louvers (94). Also, the condensed water flows, by the effect of surface tension, toward joint portions between the flat tubes (12) and the wave crest portions (14a) and the wave trough portions (14b) of the corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com