Rubber Flooring and Methods of Production Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

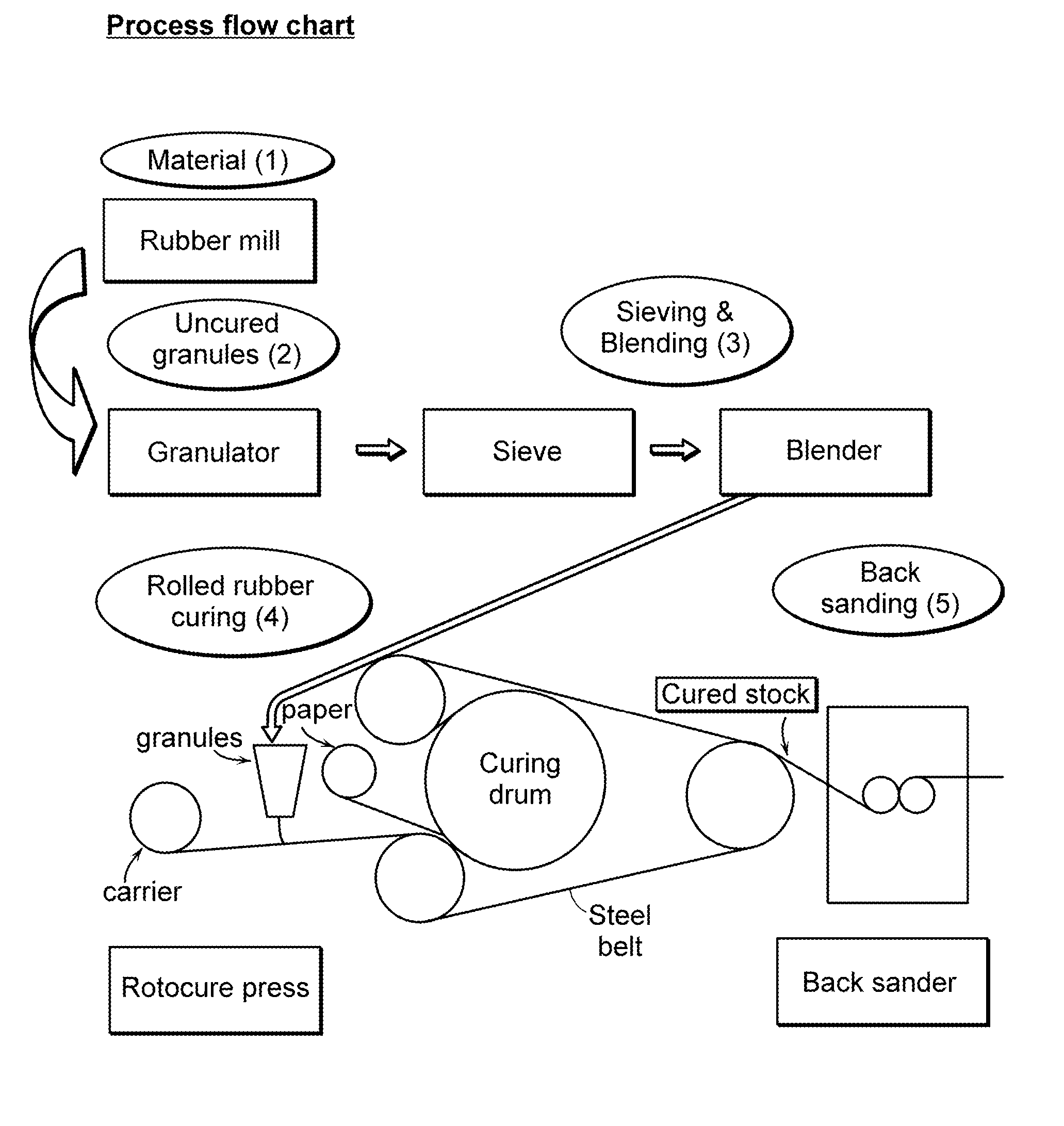

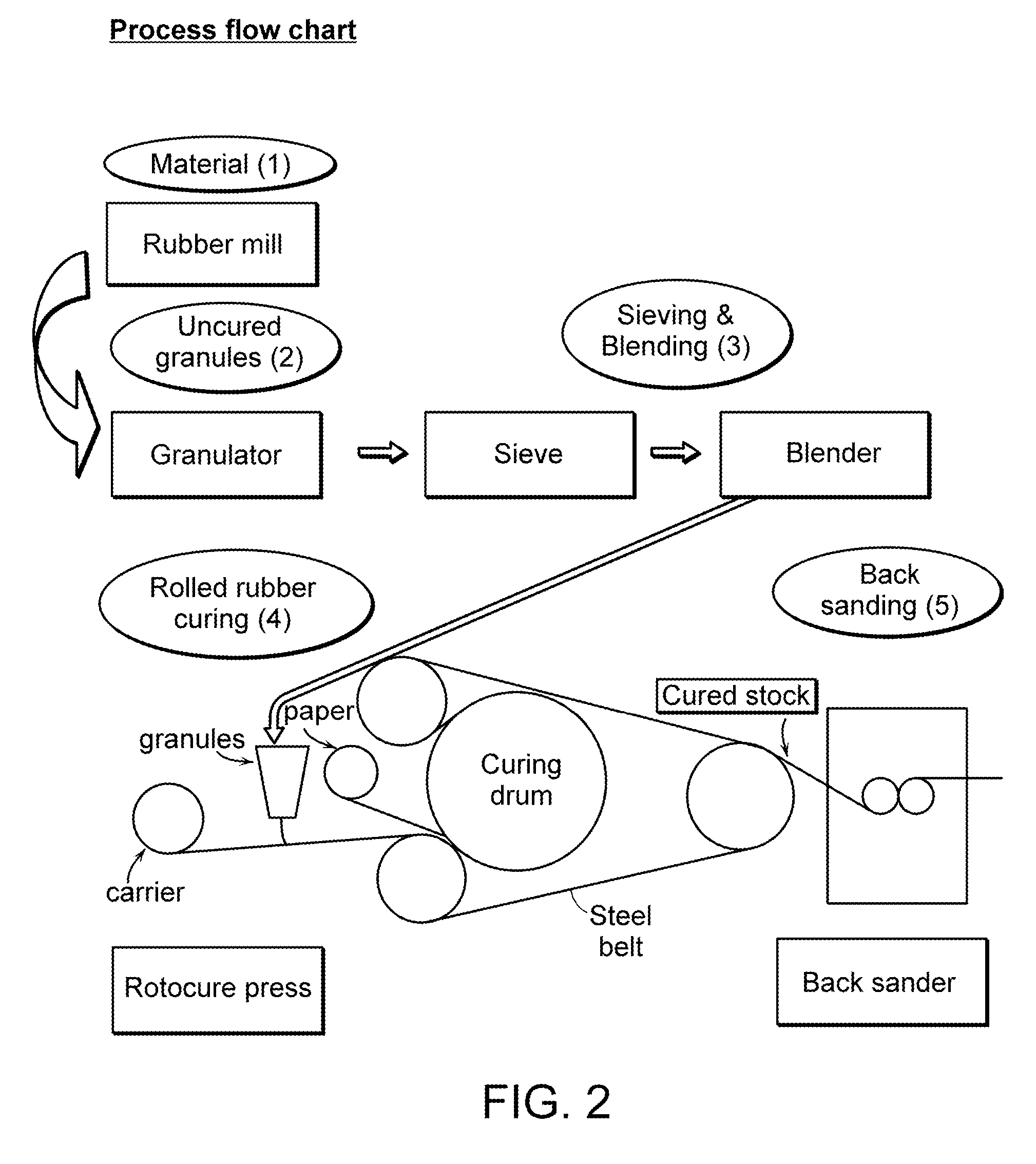

Method used

Image

Examples

Embodiment Construction

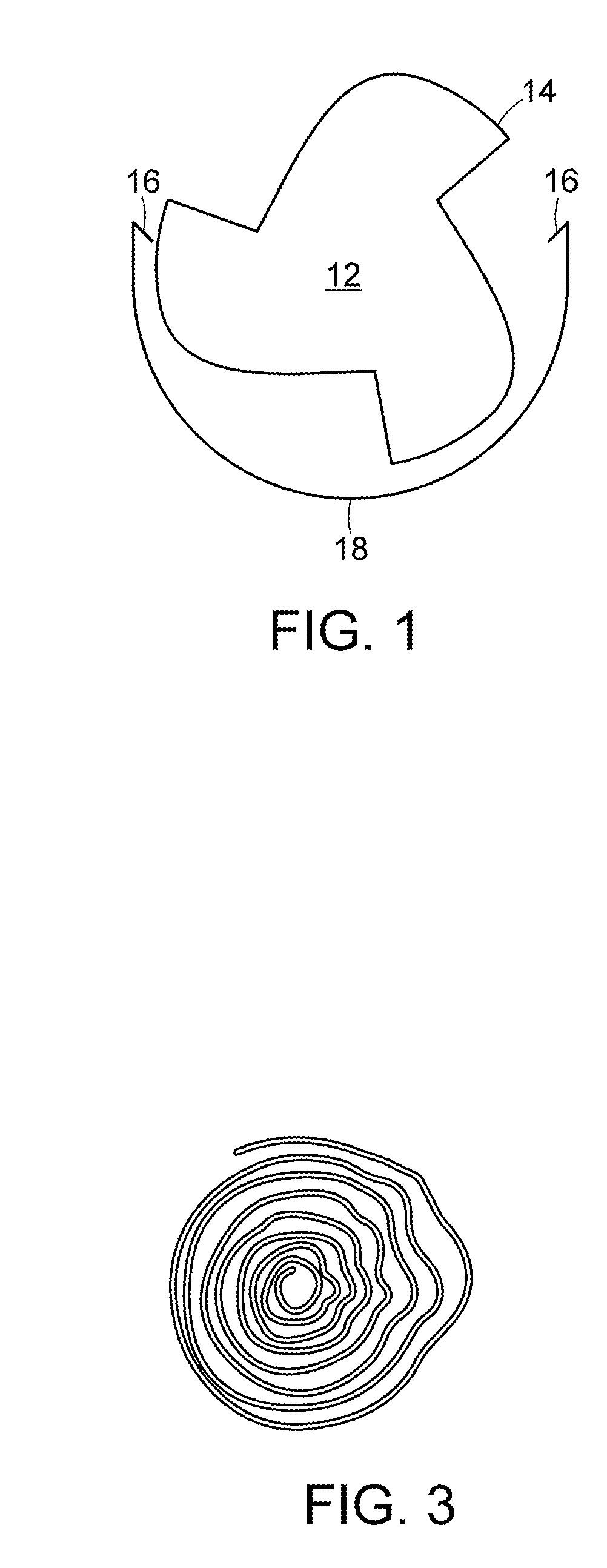

[0014] In one aspect, the present inventions provide a flooring material which in cross-section has substantially the same composition and substantially the same color along an axis from the bearing surface to the adhesion surface of the flooring material. The adhesion surface, for example, for attaching the flooring material to a substrate being on an opposing side of the material with respect to the bearing surface. The term “bearing surface” is used to refer to the surface of the flooring material which bears traffic, but such surfaces are also sometimes referred to as wear surfaces.

[0015] The present inventions are not believed to be dependent on the specific substrate material used. Rather, it is believed that any substrate material normally employed in the field can be employed in the practice of the present inventions. Accordingly, a substrate can be chosen, e.g., on the basis of manufacturing convenience, physical properties of the end product, etc.

[0016] The substrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com