Devices and methods for measuring nanometer level binding reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

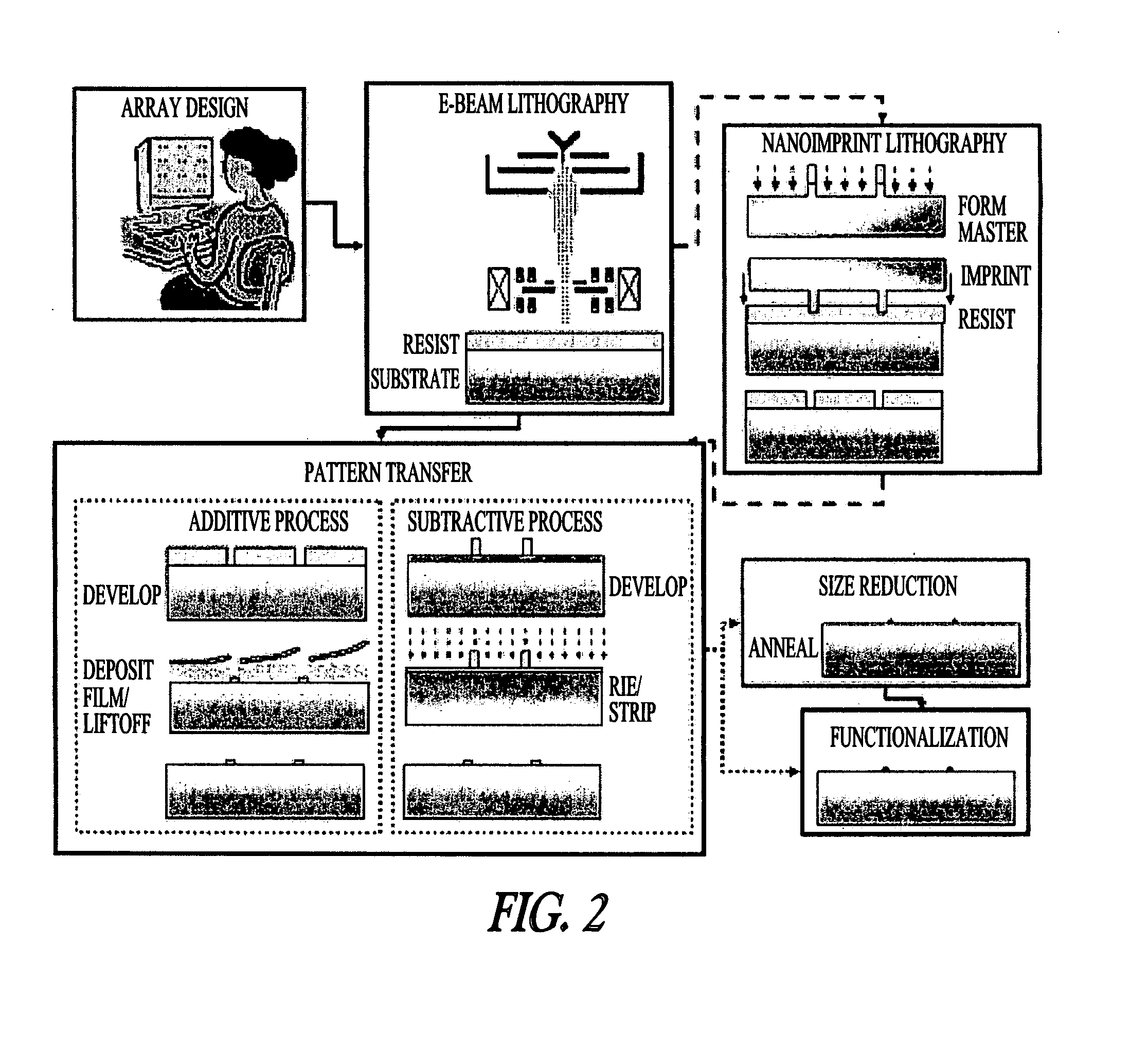

[0111] As shown in FIG. 2, a CAD software, such as CADENCE from SYNOPSIS or DESIGNCAD from IMSI, is utilized to form a pattern that can be utilized to form an array of posts. First, a thin layer of PMMA is deposited on a silicon wafer using spin casting. The pattern formed using the CAD software is transferred onto the PMMA layer utilizing electron beam lithography, such as a scanning electron microscope (FEI XL 30 SIRION) equipped with a NABITY NPGS pattern generator or a LEICA VB6-HR. After the pattern is transferred, the PMMA layer has regions of holes of approximately 5 to 20 nm. A thin layer of titanium (ranging from about 0.5 to 30 nms) is deposited on the surface of the wafer. Lift-off of the PMMA layer provides posts of titanium standing on the surface of the silicon wafer. Size reduction of the titanium posts is carried out under a non-oxidizing environment at about 400° C. for about 1 hour in argon or nitrogen gas. The titanium posts are oxidized to form posts of titanium ...

example 2

[0112] As shown in FIG. 2, a CAD software, such as CADENCE from SYNOPSIS or DESIGNCAD from IMSI, is utilized to form a pattern that can be utilized to form an array of pits. A thin layer of nickel is deposited on the silicon wafer surface followed by a thin layer of gold-palladium alloy (ranging from about 0.5 to 30 nms). The gold-palladium alloy is utilized because the grains of the gold-palladium alloy are significantly smaller than the gold and provide a smoother surface. A layer of PMMA (approximately 20 to 60 nm thick) is deposited on top of the gold-palladium alloy layer using spin casting. The pattern obtained using the CAD software is transferred onto the PMMA layer utilizing electron beam lithography, such as a scanning electron microscope (FEI XL 30 SIRION) equipped with a NABITY NPGS pattern generator or a LEICA VB6-HR. After pattern transfer, the PMMA layer has regions of holes of approximately 5 to 20 nm. Reactive ion etching or ion milling is carried out to form pits o...

example 3

[0113] As shown in FIG. 2, a CAD, such as CADENCE from SYNOPSIS or DESIGNCAD from IMSI, is utilized to form a pattern that can be utilized to form an array of pits. To carry out nanoimprint lithography, a master template is formed as follows. On a silicon wafer, PMMA layer is deposited and the pattern obtained from the CAD software is transferred onto the PMMA layer using electron beam lithography. Then, reactive ion etching or ion milling is carried to form posts of silicon. On a different silicon wafer, a layer of titanium is deposited and oxidized to form a layer of titanium dioxide. On top of the titanium dioxide layer, a layer of polystyrene is deposited using spin casting, where the thickness of the polystyrene layer is smaller or same as the height of the silicon posts described above. The silicon wafer having the polystyrene layer is heated above the glass transition temperature of the polystyrene (e.g., 180° C.) and the wafer having silicon posts is pressed onto the polysty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com