Drawer slide assembly having an adjustment mechanism

a technology of adjustment mechanism and slide assembly, which is applied in the direction of drawers, furniture parts, domestic applications, etc., can solve the problems of requiring a lot of labor and a great deal of operating force, and achieve the effect of convenient and labor-saving operation and easy mounting on the slid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

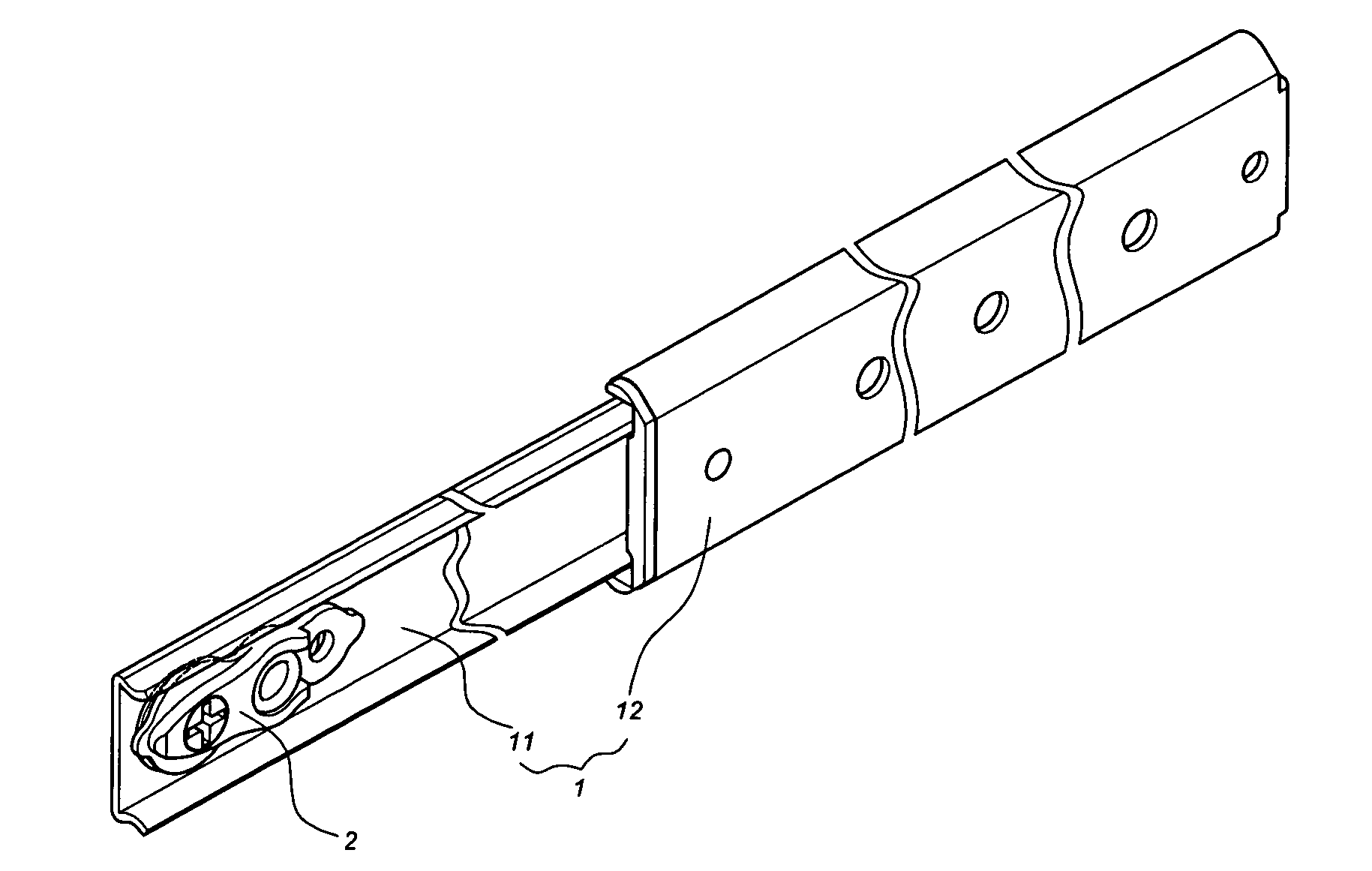

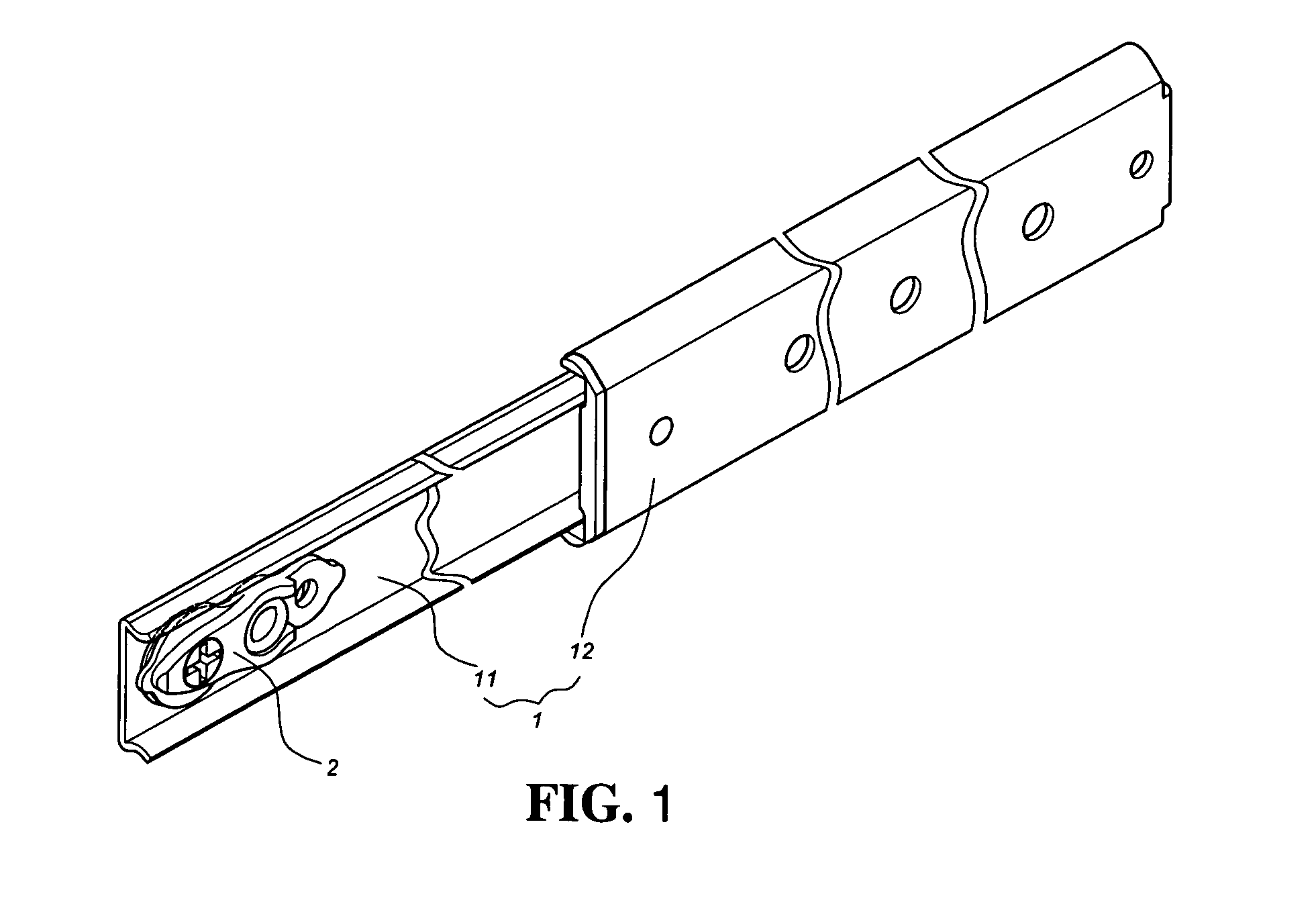

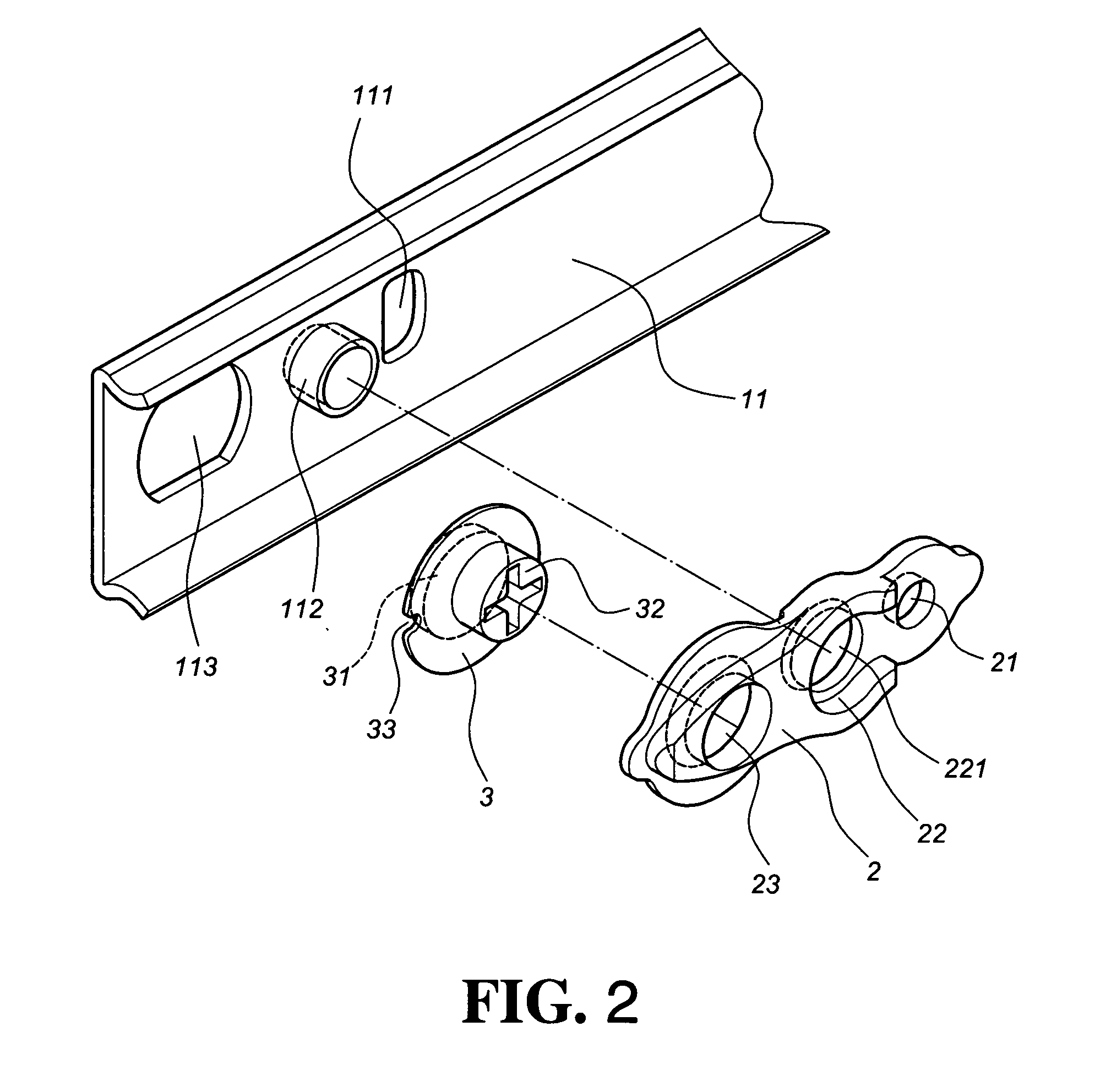

[0013]Referring to FIGS. 1 and 2, a preferred embodiment of the present invention includes a slide (1), an adjusting lever (2), and a guide block (3). The slide (1) comprises at least an inner rail (11) and an outer rail (12). The inner rail (11) penetrates through the outer rail (12). A first aperture (111), a pivoting part (112), and a second aperture (113) are disposed on a front end of the inner rail (11) of the slide (1). The first aperture (111) is a vertical aperture and the second aperture (113) is a horizontal aperture. The adjusting lever (2) comprises a first end (21), a middle section (22) and a second end (23). A pivoting hole (221) is disposed in the middle section (22) of the adjusting lever (2). The pivoting part (112) on the inner rail (11) is formed with a hollow tube to penetrate through the pivoting hole (221) for the adjusting lever (2) to be pivoted to the inner rail (11) in a fashion of riveting as shown in the preferred embodiment. The first end (21) of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com