Clothes rack available for dustproof jacket

a clothes rack and dustproof technology, applied in the field of clothes racks, can solve the problems of increasing the cost of assembly of clothes racks, inconvenience in packaging, storage and transportation of clothes racks, and reducing the cost of fabrication, so as to improve the working efficiency and reduce the cost of fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

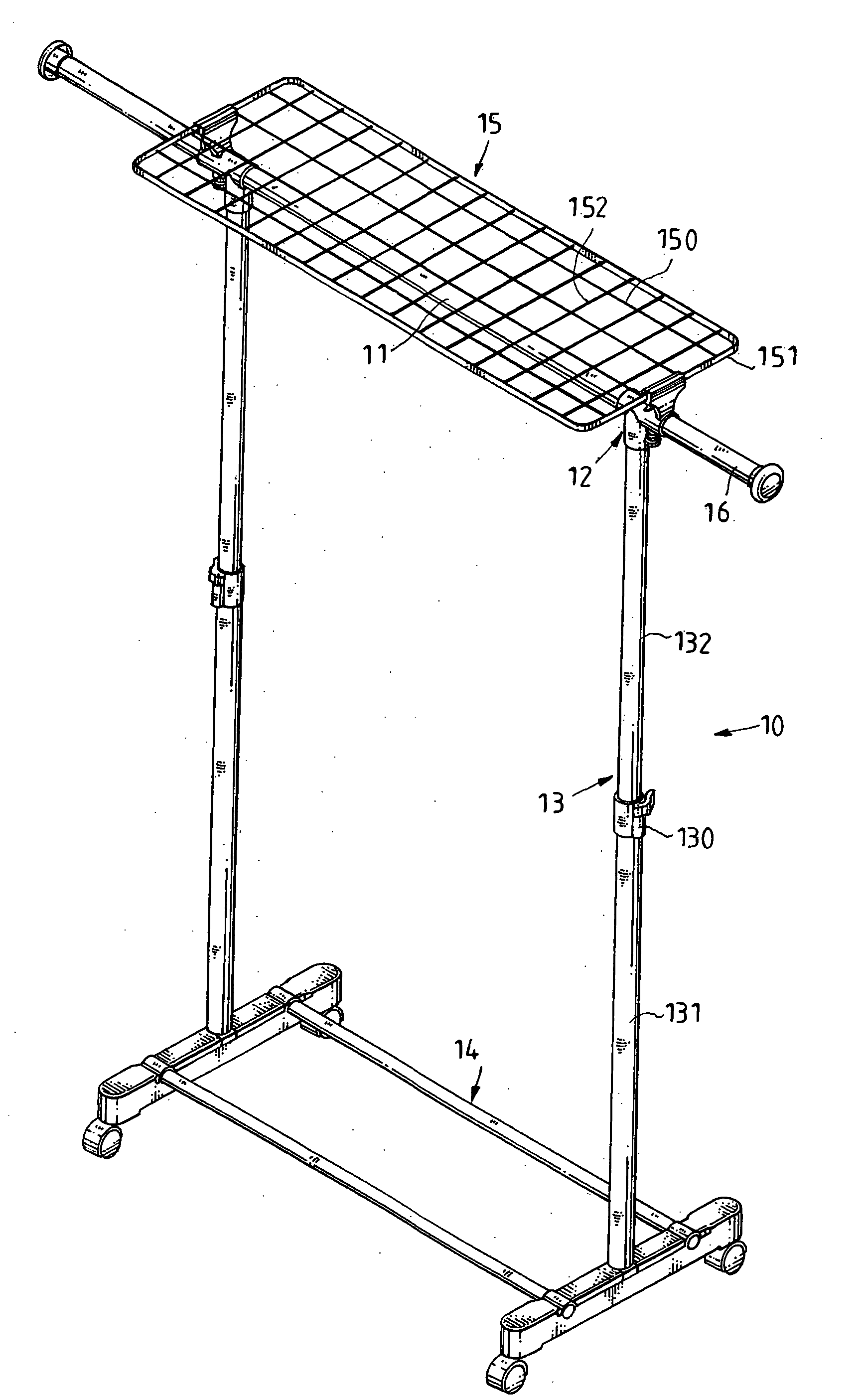

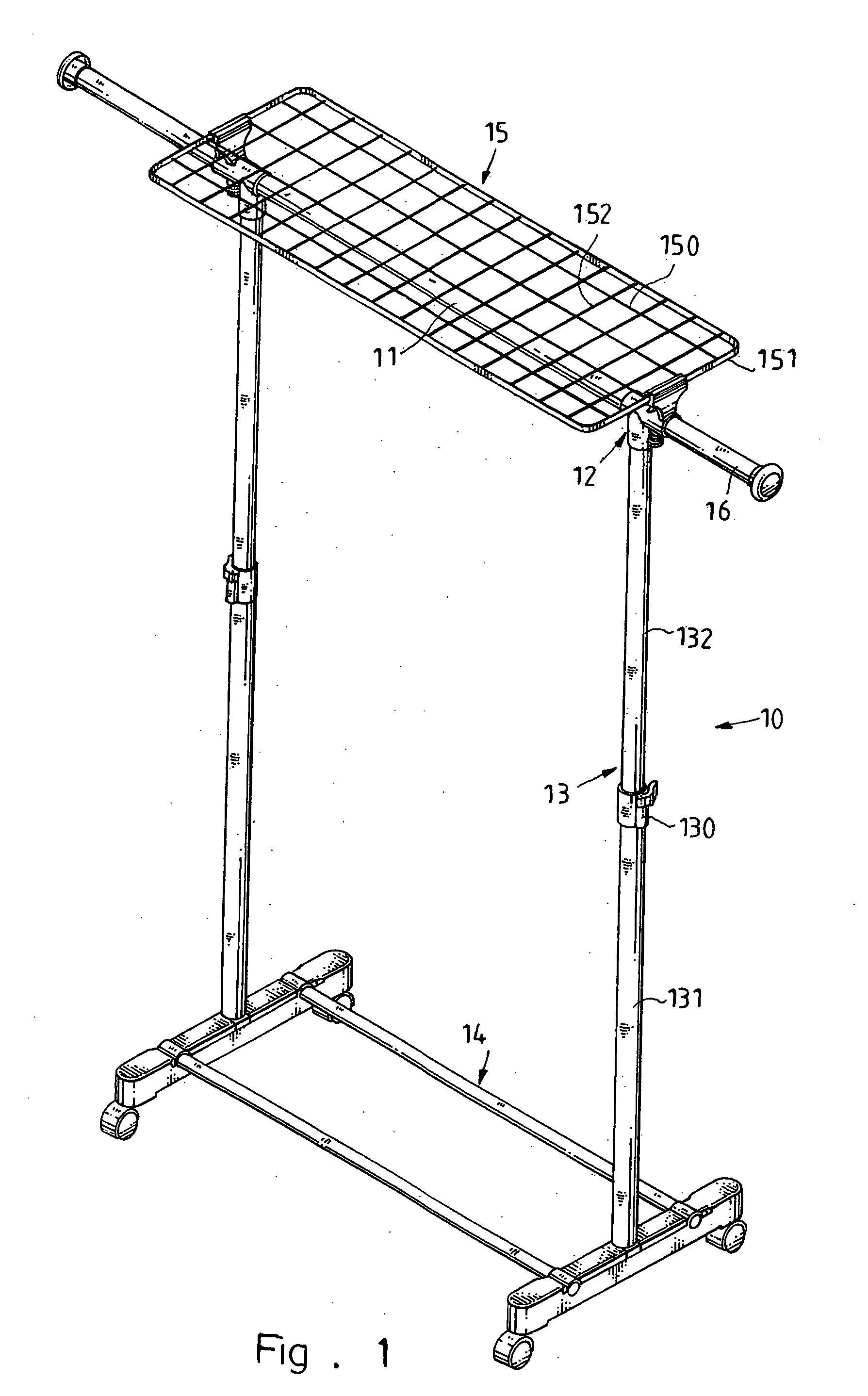

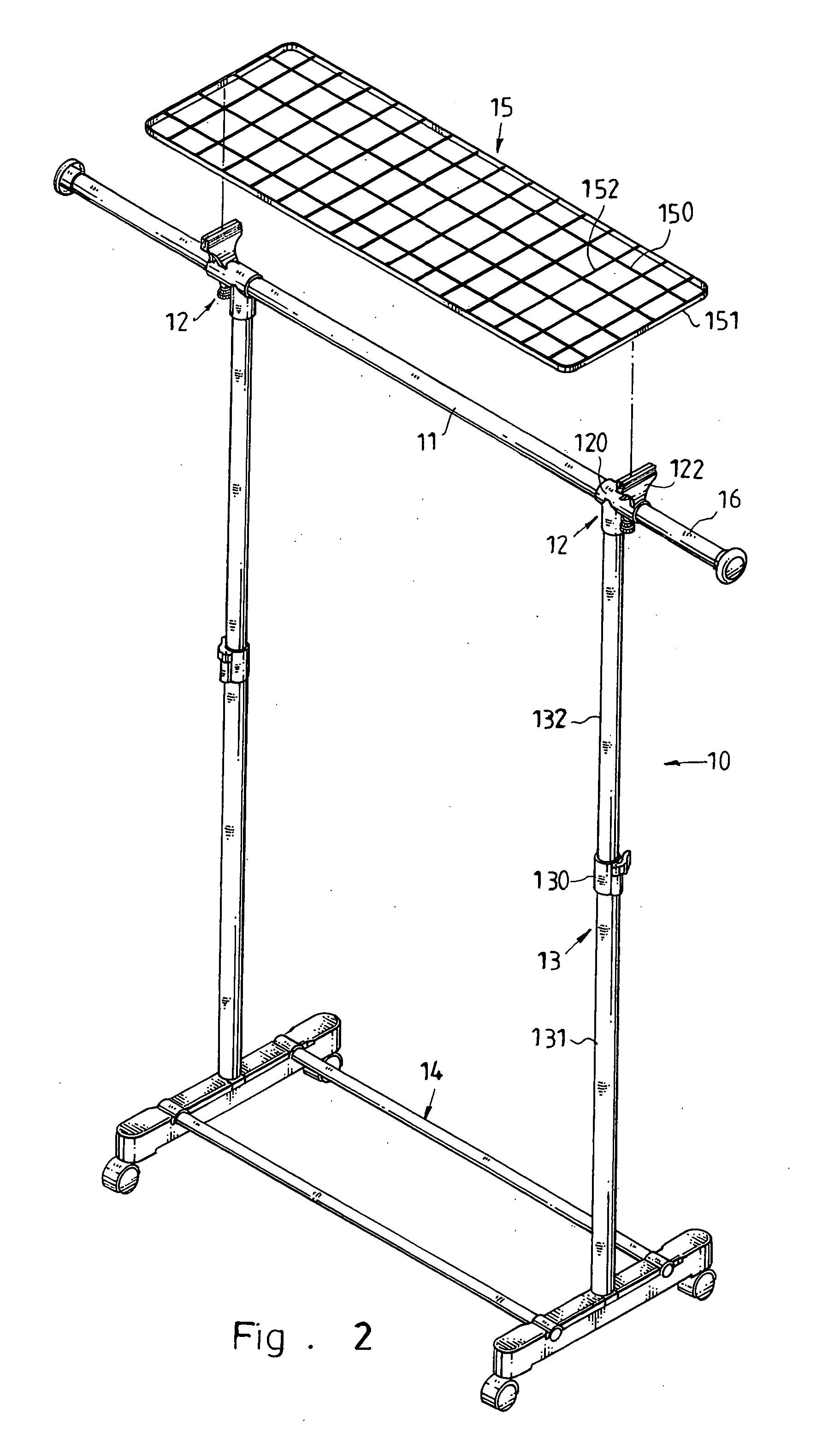

[0019]Referring to the drawings and initially to FIGS. 1 and 2, a clothes rack 10 in accordance with the preferred embodiment of the present invention comprises a hanging tube 11, two spaced connectors 12 each mounted on the hanging tube 11, two retractable uprights 13 each having an upper portion connected to the respective connector 12 and a lower portion connected to a stand 14, two substantially T-shaped support seats122 each mounted on the respective connector 12, and a top frame 15 detachably mounted between the two support seats 122.

[0020]The hanging tube 11 has two ends each provided with a secondary tube 16.

[0021]Each of the two connectors 12 is substantially T-shaped and has a sleeve 120 mounted on the hanging tube 11, and each of the two support seats 122 is mounted on the sleeve 120 of the respective connector 12.

[0022]Each of the two retractable uprights 13 includes an outer tube 131 having a lower end mounted on the stand 14, an inner tube 132 retractably mounted in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com