Magnetoresistive effect element, thin-film magnetic head, method for manufacturing magnetoresistive effect element, and method for manufacturing thin-film magnetic head

a technology of magnetoresistive effect and magnetic head, which is applied in the direction of nanomagnetism, data recording, instruments, etc., can solve the problems of inability to improve the the degradation mode becomes a problem, and the under and over layers are inevitably thin, so as to achieve sufficient bias magnetic field, sufficient crystallinity of the end portion of the magnetic domain controlling bias layer, and the effect o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

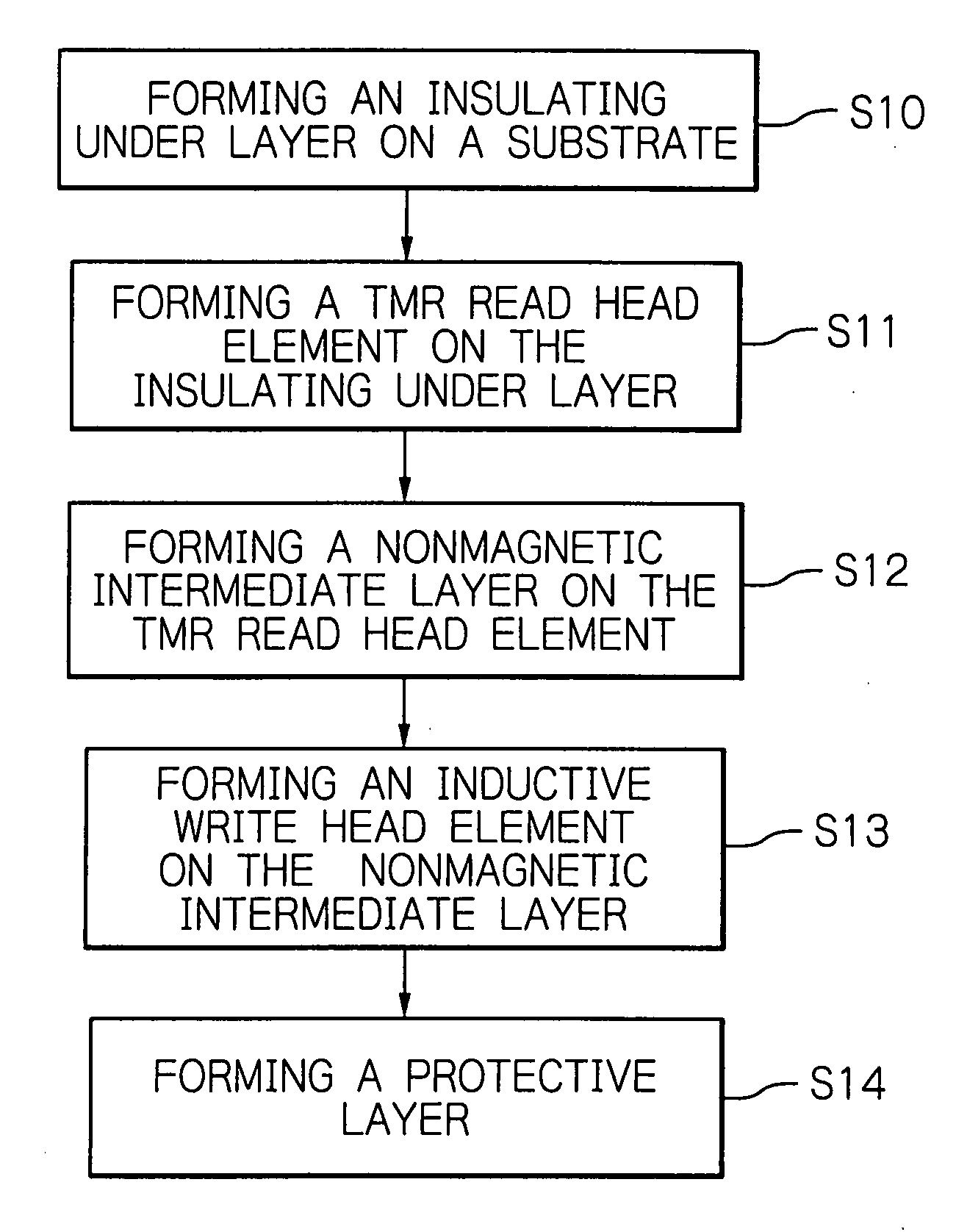

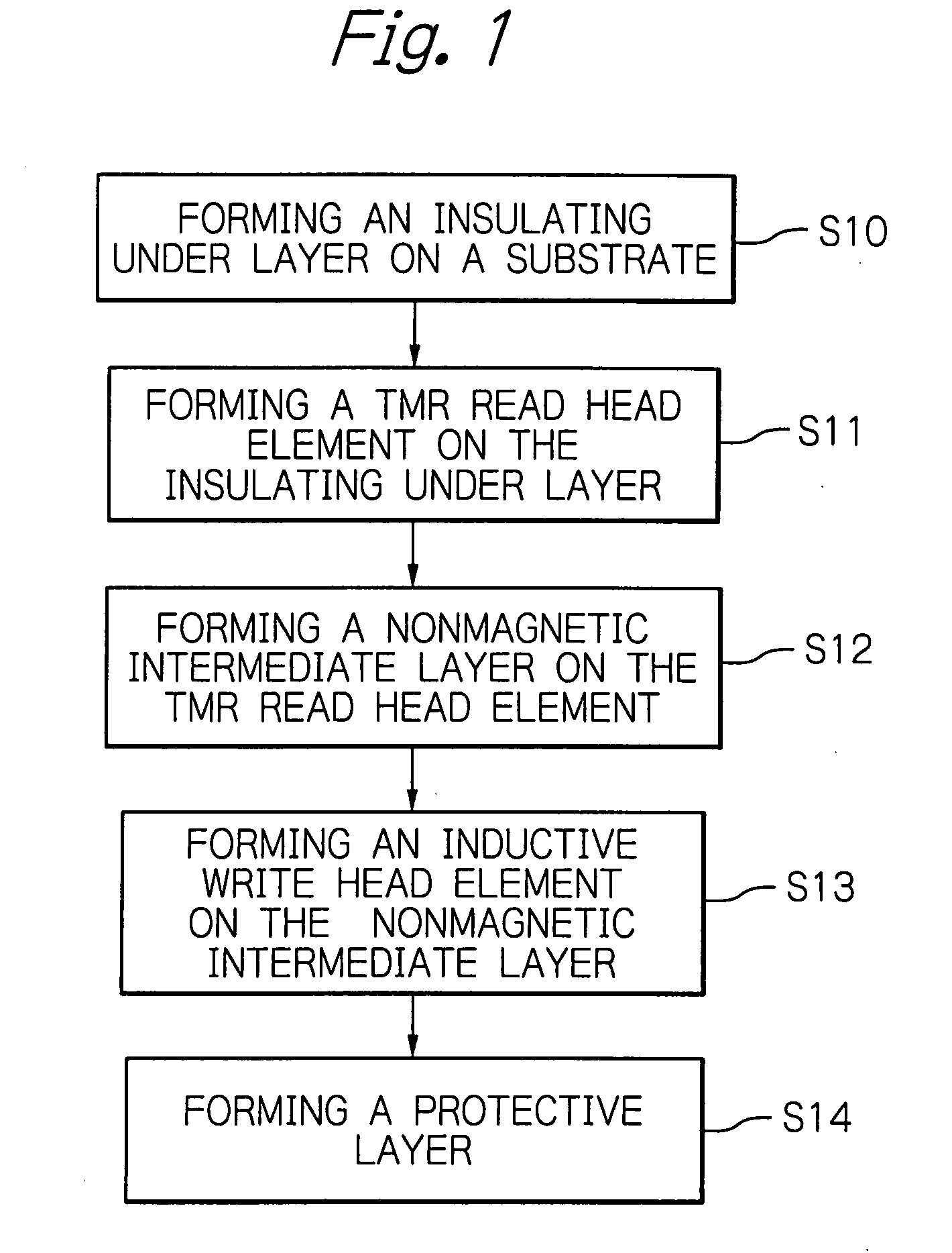

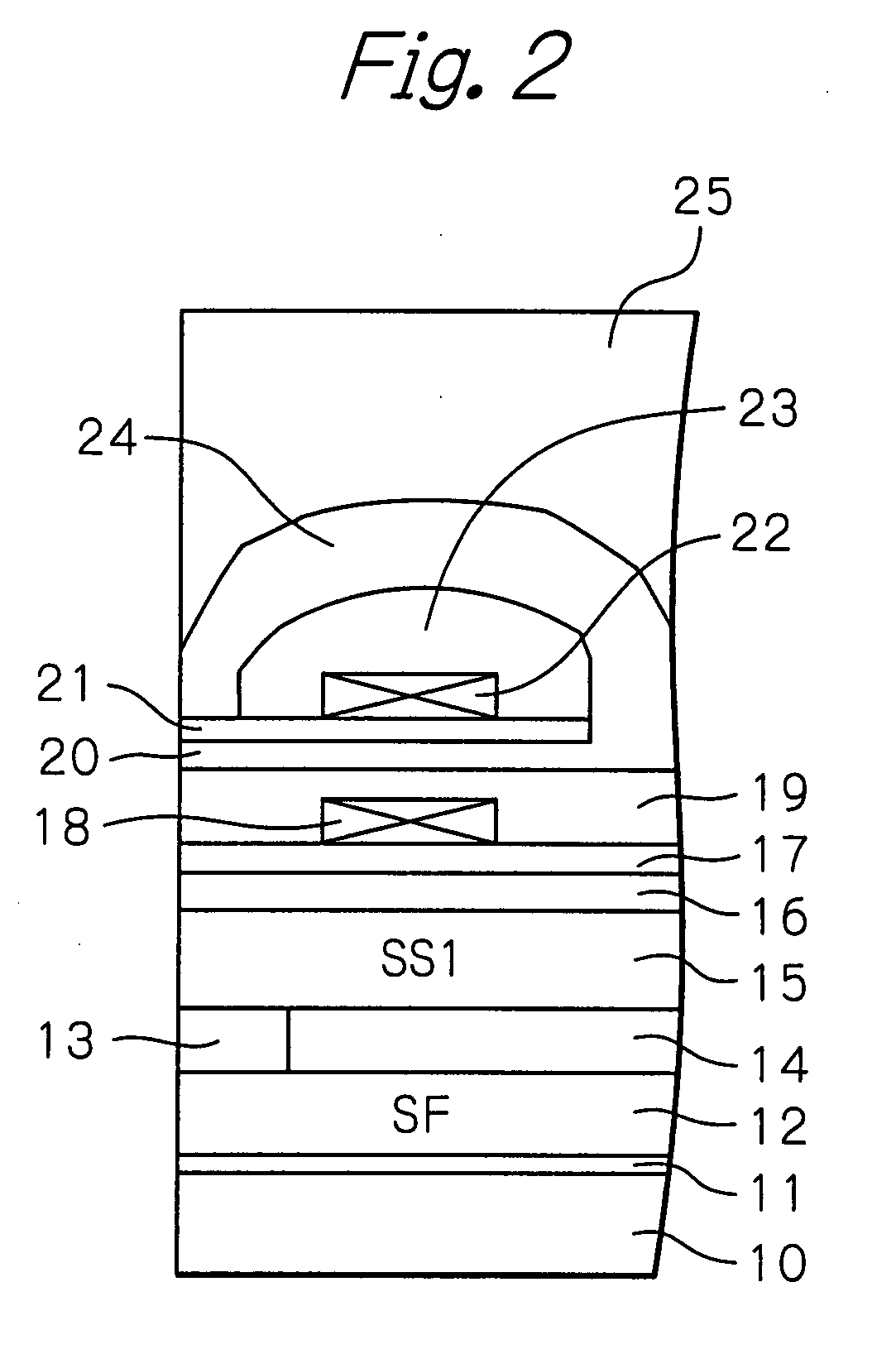

[0043]FIG. 1 is a flowchart illustrating a process for manufacturing a thin-film magnetic head according to an embodiment of the present invention, FIG. 2 is a cross-sectional view schematically showing a configuration of the thin-film magnetic head manufactured according to the embodiment shown in FIG. 1, FIG. 3 is a flowchart illustrating in detail a process for manufacturing a read head element in the manufacturing process shown in FIG. 1, and FIGS. 4a to 4c are cross-sectional views illustrating the manufacturing process shown in FIG. 3. The cross-section shown in FIG. 2 is a plane perpendicular to the ABS and the track-width direction of the thin-film magnetic head, and the cross-sections in FIGS. 4a to 4c are parallel to the ABS of the thin-film magnetic head.

[0044]While the magnetic head manufactured in this embodiment is a TMR thin-film magnetic head, a GMR thin-film magnetic head having the CPP structure can be manufactured as well using basically the same manufacturing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com