Walking cane assembly

a walking cane and assembly technology, applied in the field of collapsible walking cane assembly, can solve the problems of reducing his/her stability, and achieve the effect of quick and easy adjustment and readily adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

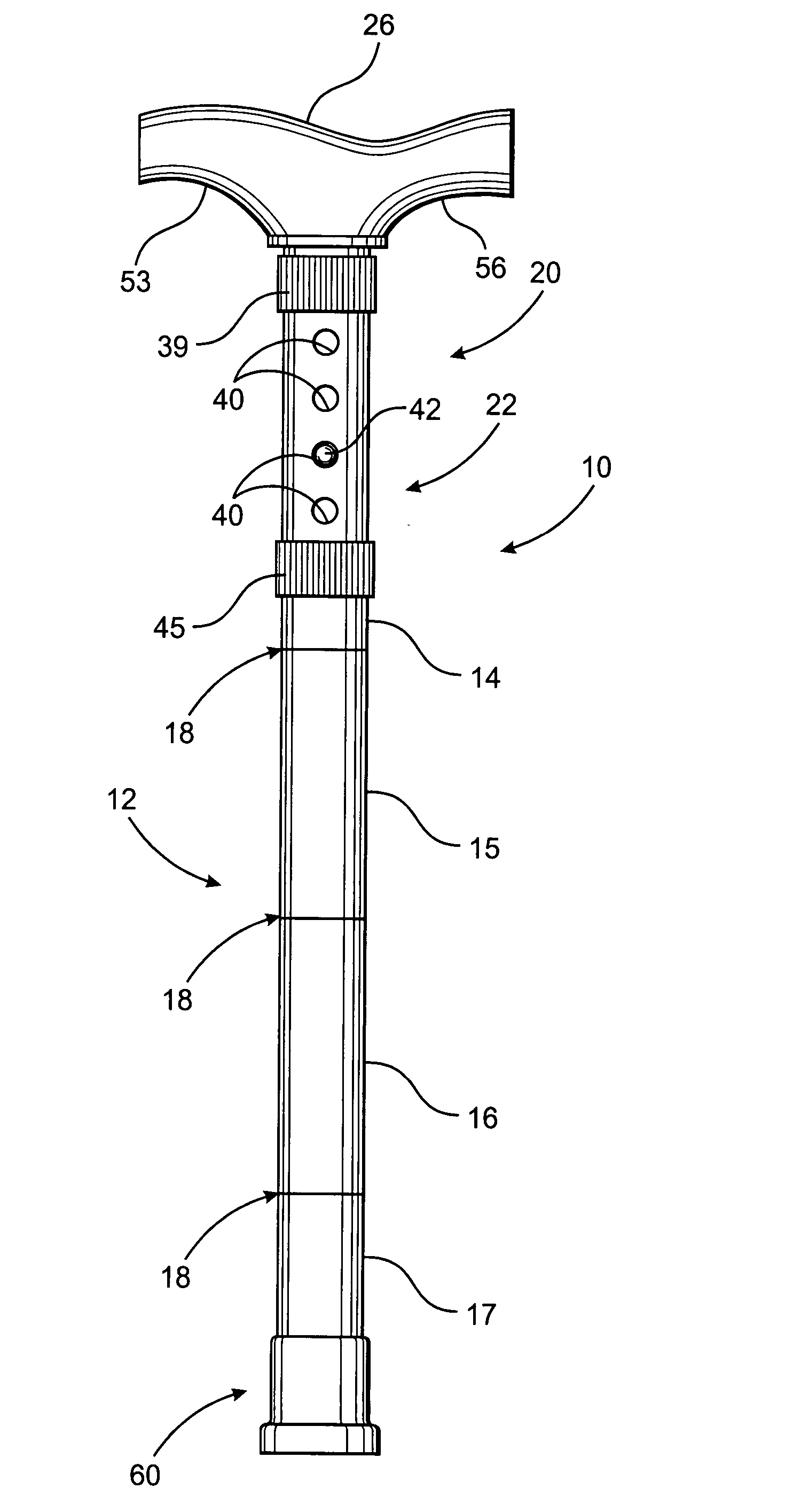

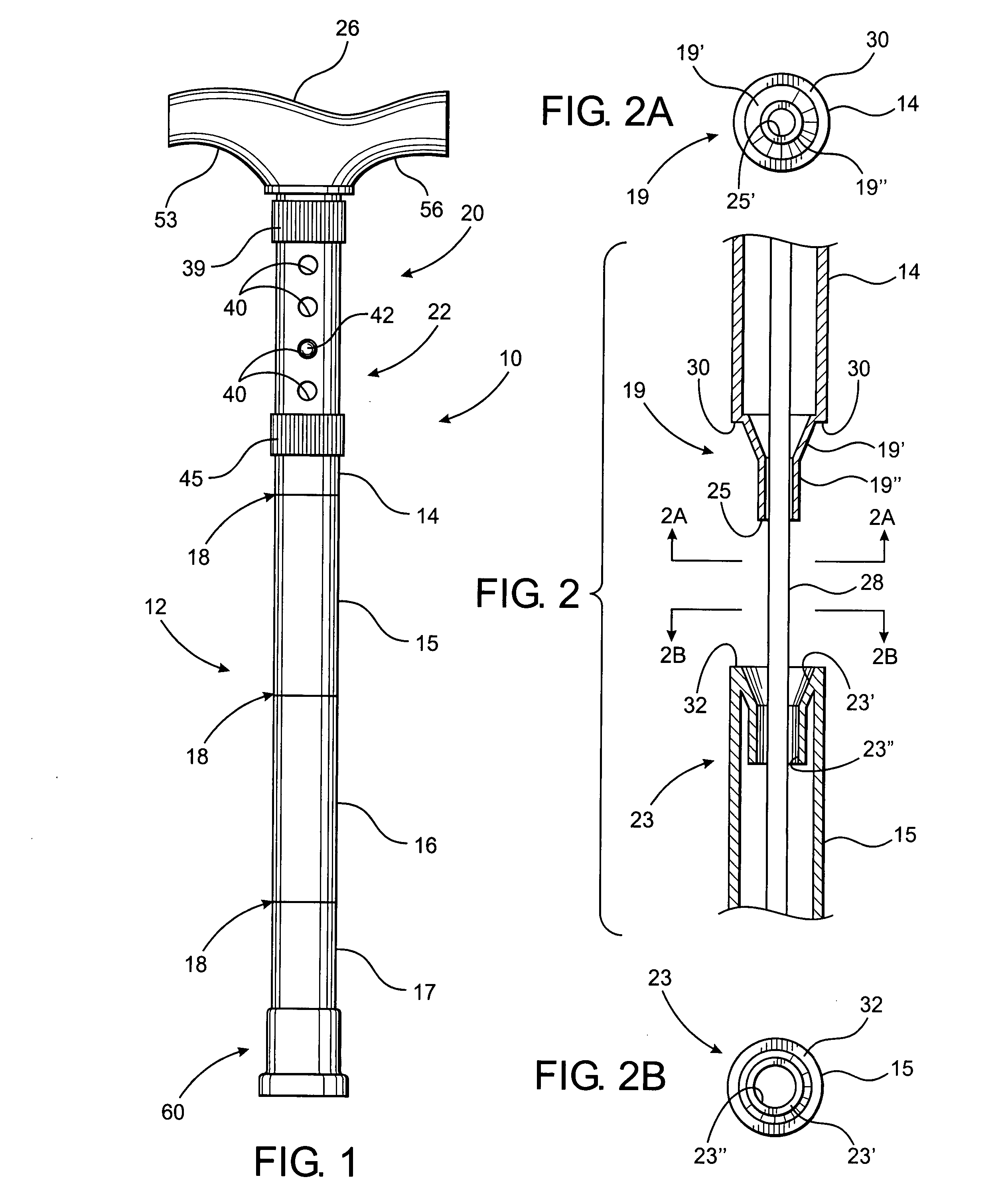

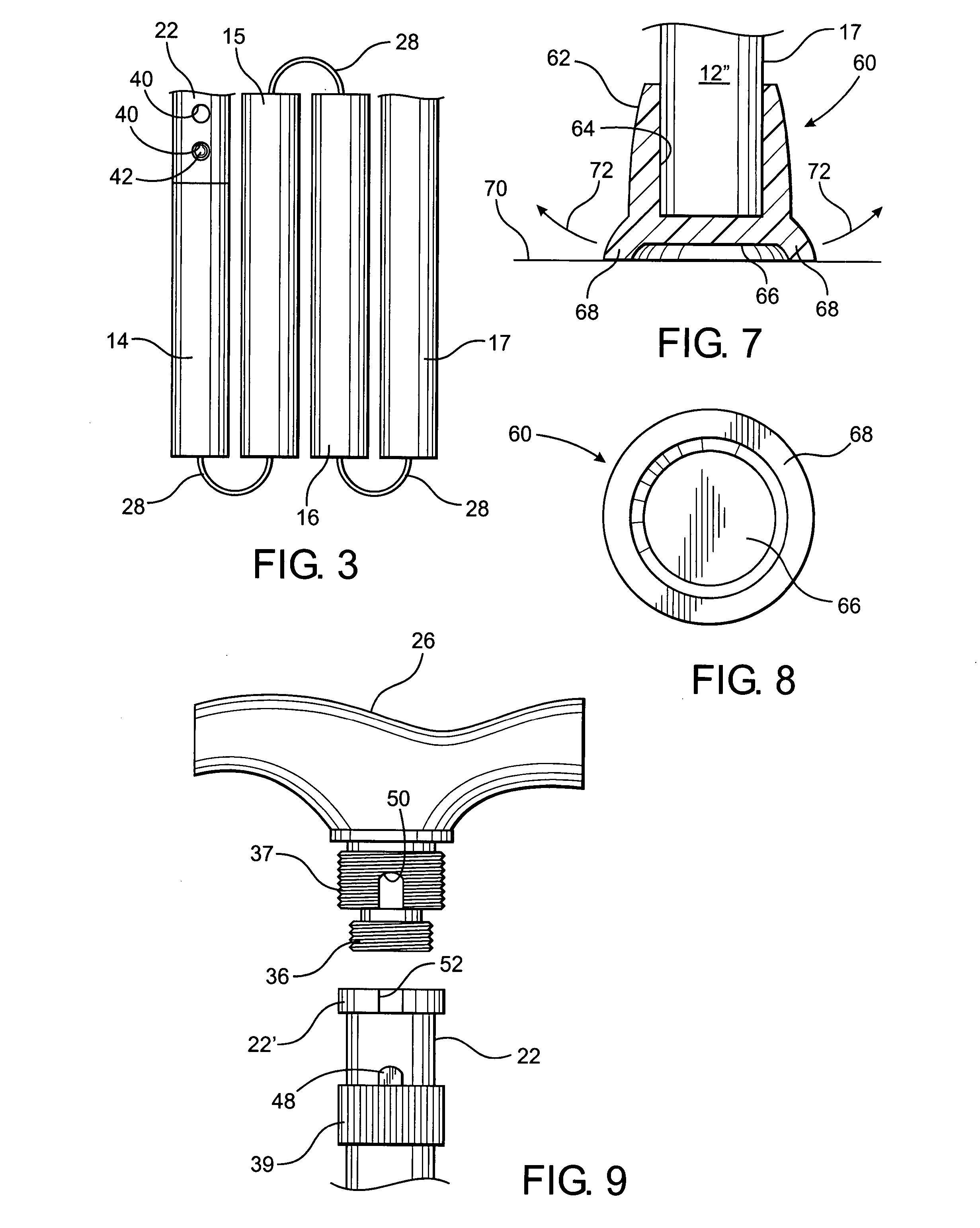

[0035] As shown in the accompany drawings, the present invention is directed to a walking cane assembly generally indicated as 10 and comprising a shaft generally indicated as 12 which is represented in FIG. 1 in its operative position. When so positioned, the shaft 12, comprises a plurality of elongated sections 14, 15, 16, 17, etc. disposed into a coaxial orientation. The specific number of the elongated sections 14 through 17 may vary. However, there should be at least two of such sections to facilitate disposition of the cane assembly 10 in the collapsed position of FIG. 3. By way of example only the preferred embodiment of FIG. 1, comprises four elongated sections. As described in greater detail hereinafter, the primary reference to FIGS. 2, 2a and 2b, adjacent ones of the plurality of elongated sections 14 through 17 are interconnected by a joint assembly 18 which facilitates the selective disposition of the sections 14 through 17 in either the operative position of FIG. 1 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com