Single piece rotary wrenching tool

a rotary wrench and single-piece technology, applied in the field of single-piece rotary wrenching tools, can solve the problems of inefficient torquing ability and decrease the deformation of the fastener, and achieve the effects of reducing the number of wrenches, tightening the space, and reducing the depth of the crown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

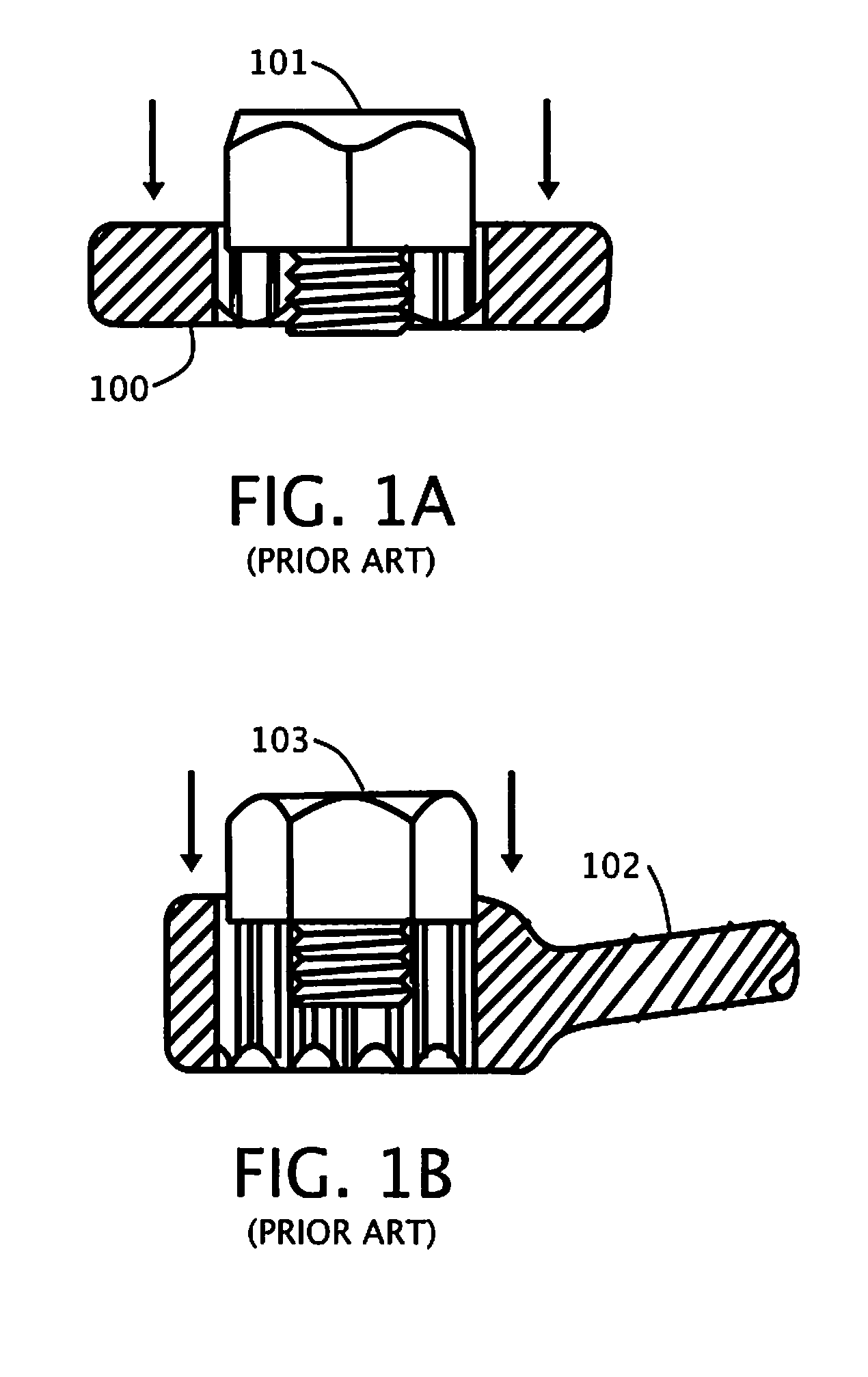

[0024]FIG. 1A depicts a traditional open end wrench. A traditional open end wrench 100 slips by when the user applies it on a hex fastener 101.

[0025]FIG. 1B depicts a traditional box wrench. A traditional box wrench 102 makes a partial contact with a hex fastener 103.

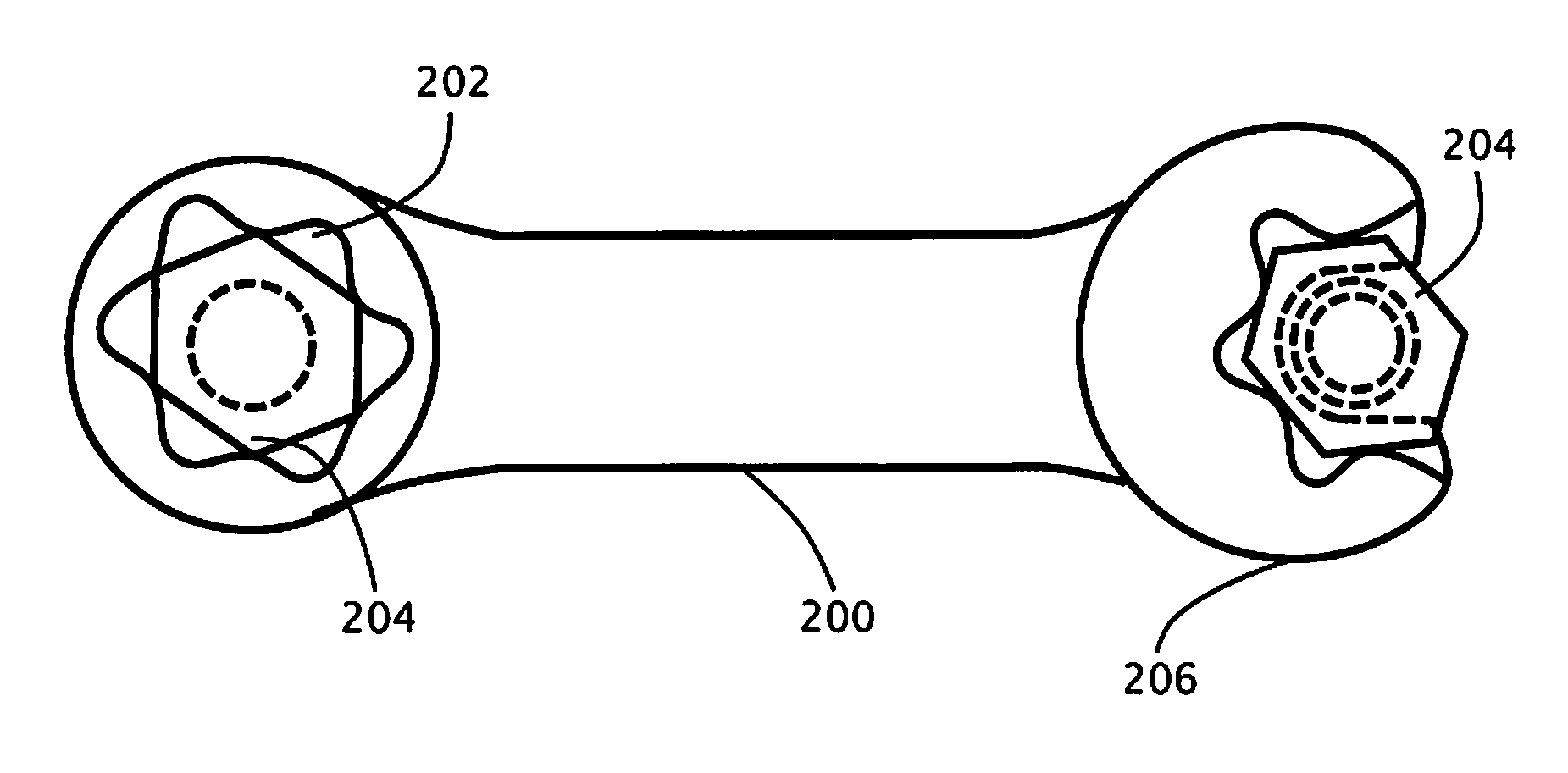

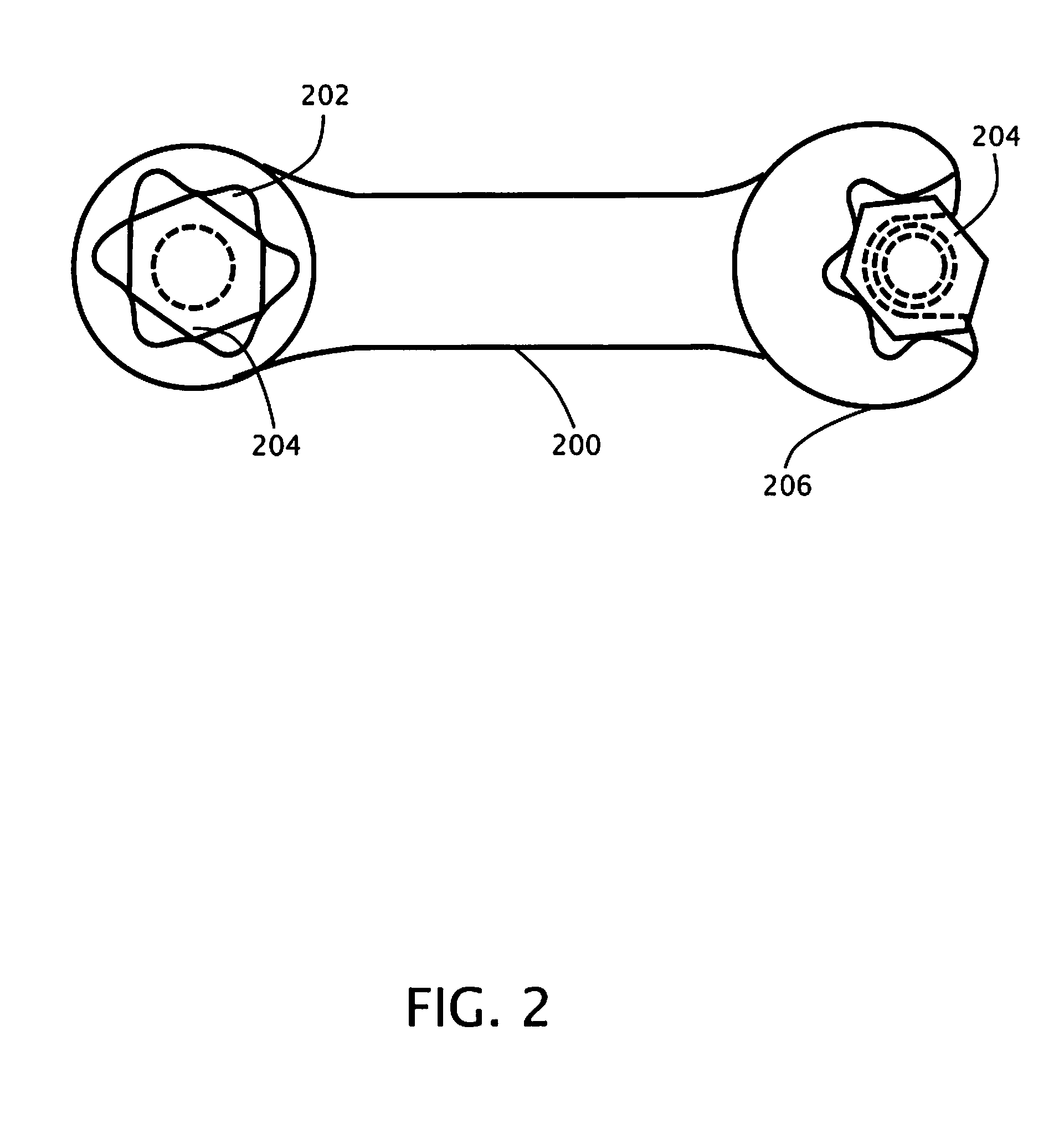

[0026]FIG. 2 illustrates a schematic view of a duplex open wrench 200 according to one embodiment of the present invention. In FIG. 2, six inwardly projecting lobes of the same size 202 within a uniform interior of the duplex wrench 200 enable the wrench 200 to exert pressure on the flats of hexagonal object 204 away from the flats. The crown 206 in the duplex open wrench has four faces to contact the hexagonal object 204 and thus distributes the stresses over four hex flats of hexagonal object 204.

[0027]FIG. 3 illustrates a schematic view of a duplex box wrench according to one embodiment of the present invention. A wrench with a two-sided crown 300, a tapered internal guide 302, a head 304, and a shank 306 are disclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com