Heat spreader for a multi-chip package

a multi-chip package and heat spreader technology, applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of device failure, reliability and performance deficiencies, and mismatches in the coefficient of thermal expansion (cte)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

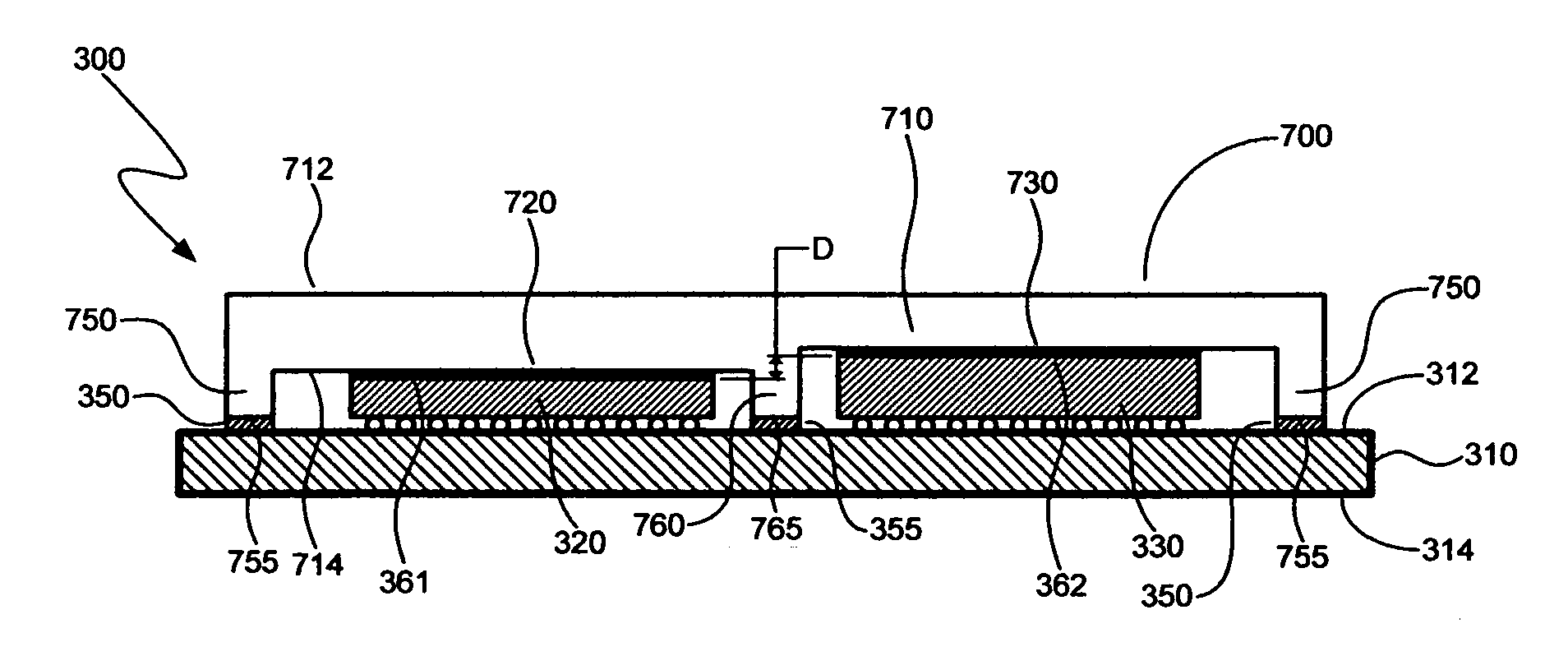

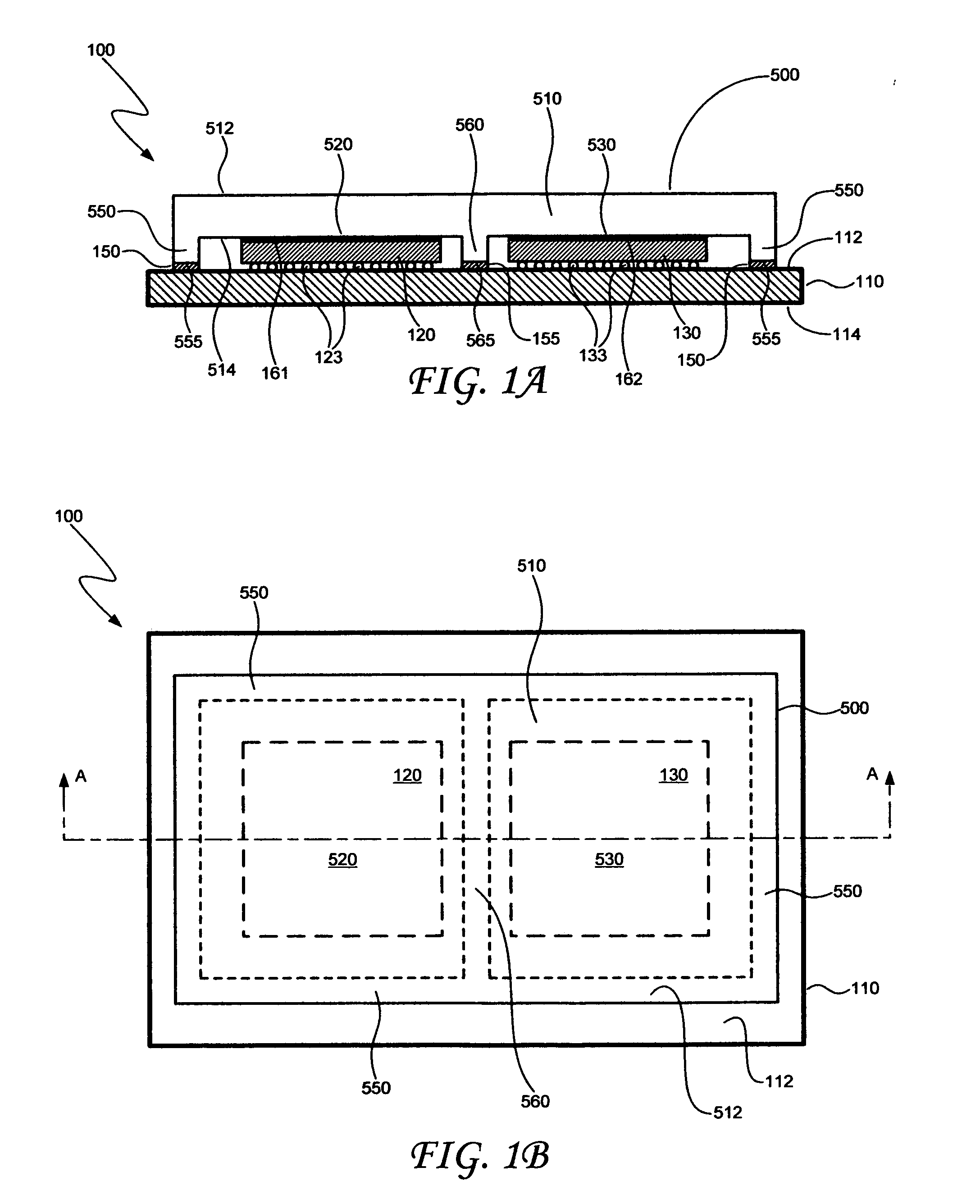

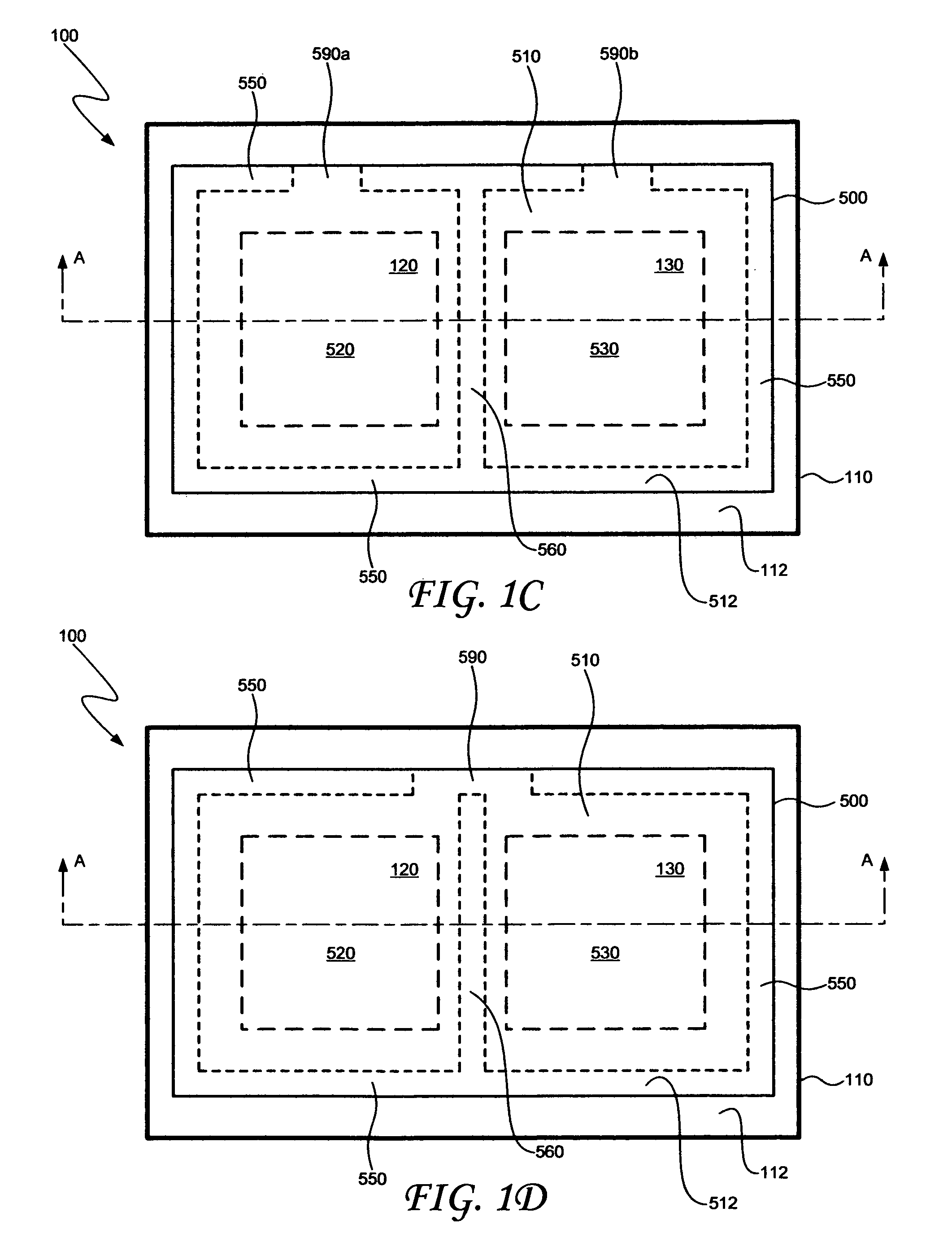

[0009]Referring to FIGS. 1A and 1B, illustrated is a multi-chip package 100. A plan view of the multi-chip package 100 is shown in FIG. 1B, whereas a cross-sectional elevation view of the package 100, as taken along line A-A of FIG. B, is shown in FIG. 1A. The multi-chip package 100 includes a substrate 110, a first integrated circuit (IC) die 120, a second IC die 130, and an embodiment of a heat spreader 500. The heat spreader 500 includes a member (e.g., a wall) extending between the heat spreader's body and the underlying substrate 110, and this member can stiffen the package and reduce warpage of the substrate 110. By reducing substrate warpage, the heat spreader 500 may assist in minimizing failures, such as thermal interface delamination, which can lead to improved reliability. Embodiments of this heat spreader are described in greater detail below.

[0010]The substrate 110 may comprise any suitable type of package substrate or other die carrier. In one embodiment, the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com