Sandbag Wall System with United Sandbags

a sandbag and wall technology, applied in soil preservation, artificial islands, dykes, etc., can solve the problem of limited bag fill volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

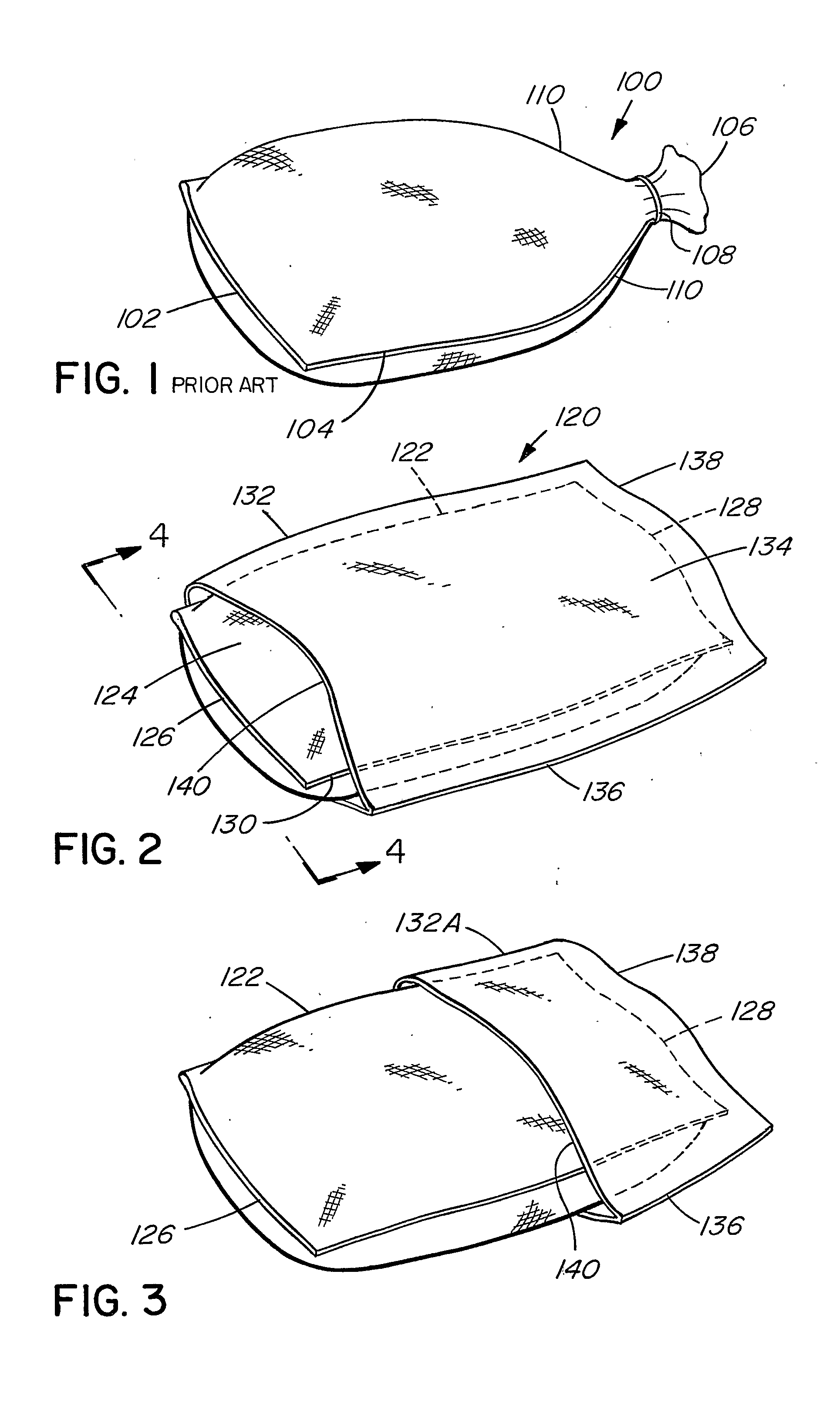

[0011]The invention provides wall-building units comprising a combination of two bags. A prior art sandbag containing fill material is shown in FIG. 1. Prior art bag 100 has sewn bottom edge 102 and a side edge 104. It is tied closed at top edge 106 by means of a tie 108. In order to be able to fill the bag, the top edge is pulled together in a cinched configuration, as a result of which the bag cannot be filled to its top edge. The shoulders 110 reflect the reduction in fill volume resulting from this closing requirement.

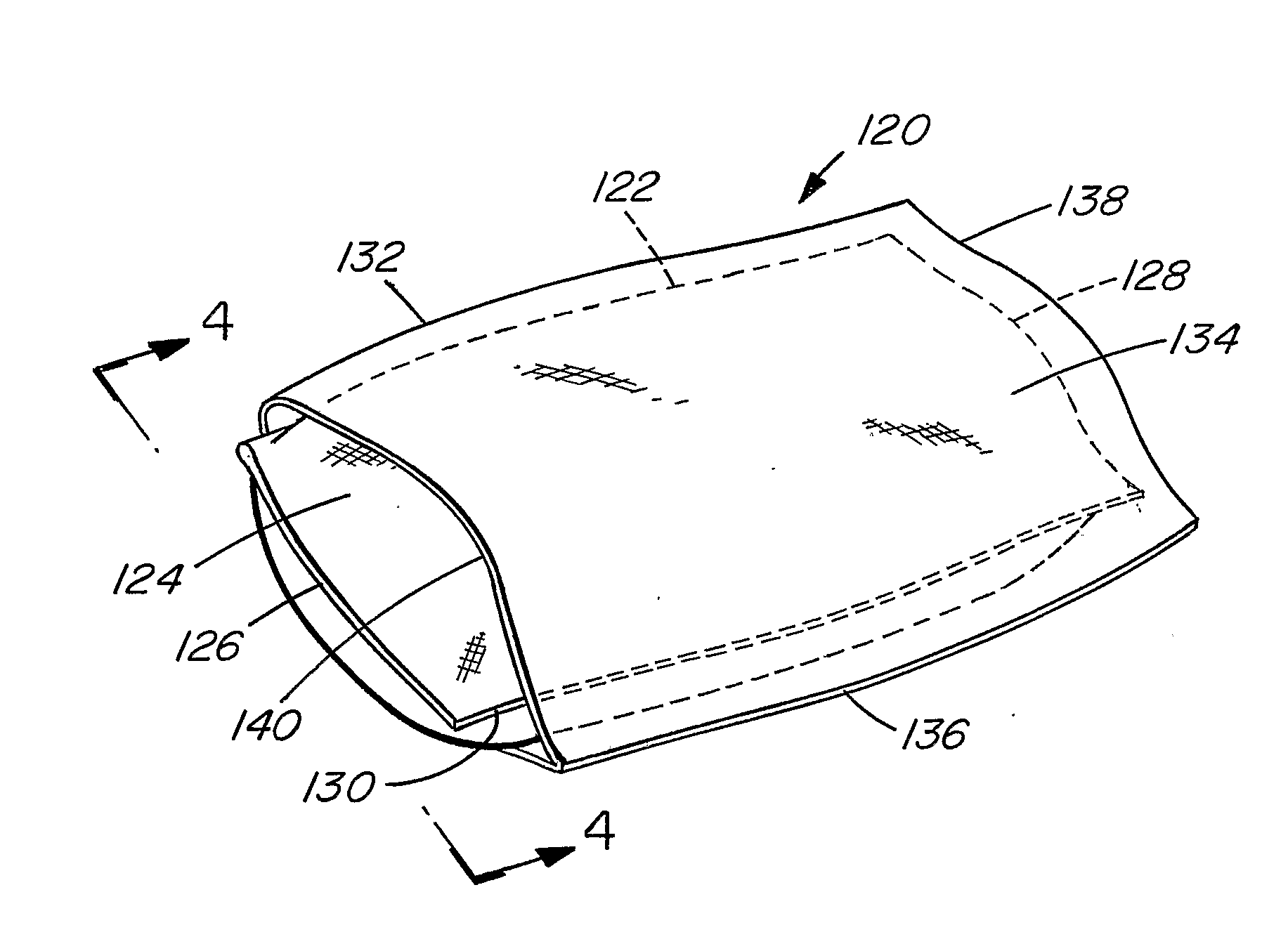

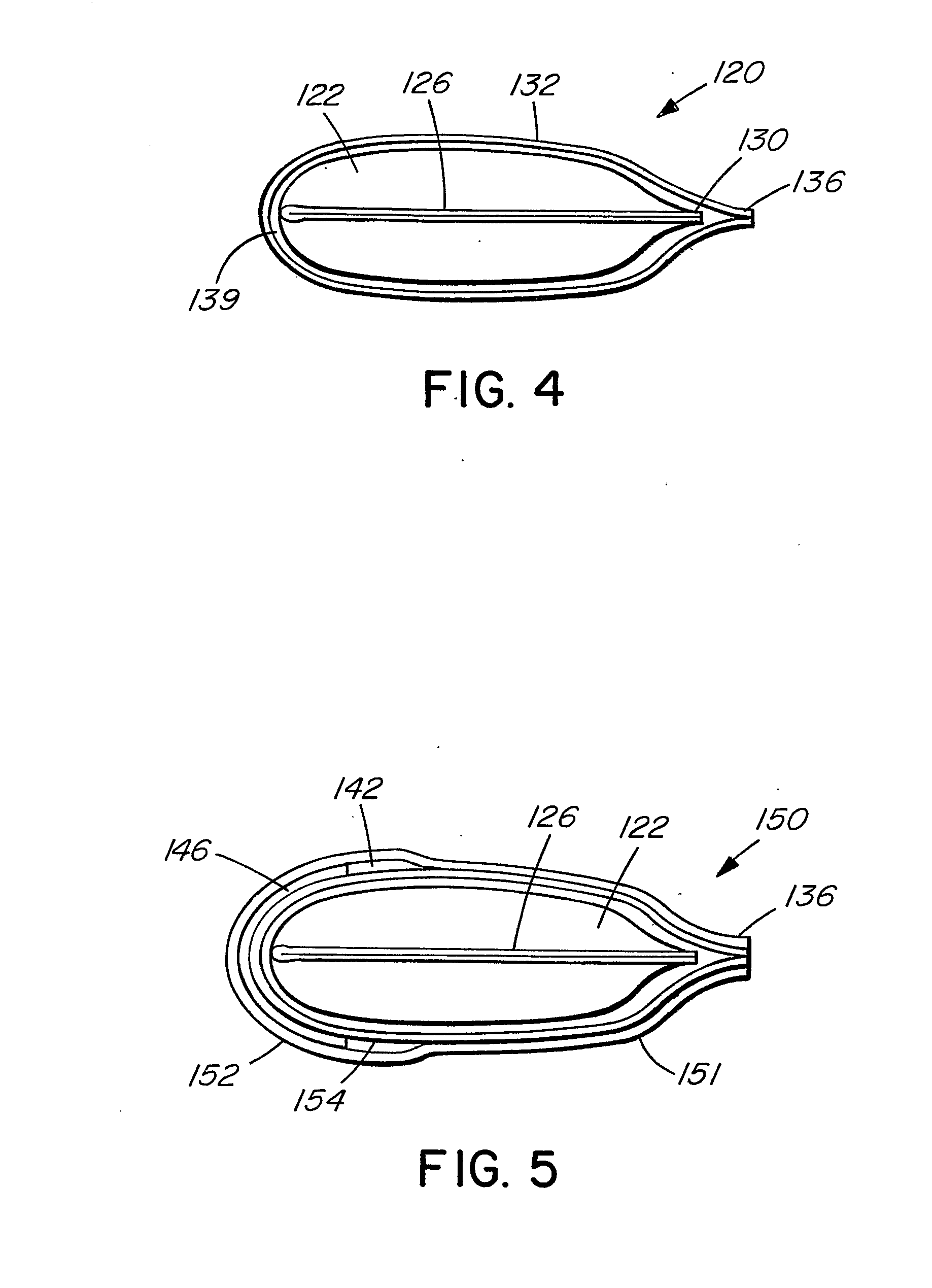

[0012]In wall-building unit 120, shown in FIGS. 2 and 4, this loss in fill volume is eliminated. Inner bag 122 has a bag wall 124, a closed bottom 126 and an open top edge 128. The bag wall 124 is sewn closed along longitudinal edge 130. Outer bag 132 is of equivalent structure, with a bag wall 134 sewn along longitudinal edge 136, and a closed bottom 138 and an open top edge 140. The outer bag is positioned to extend longitudinally over the inner bag 122 so that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com