Power source device and battery cooling structure for vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

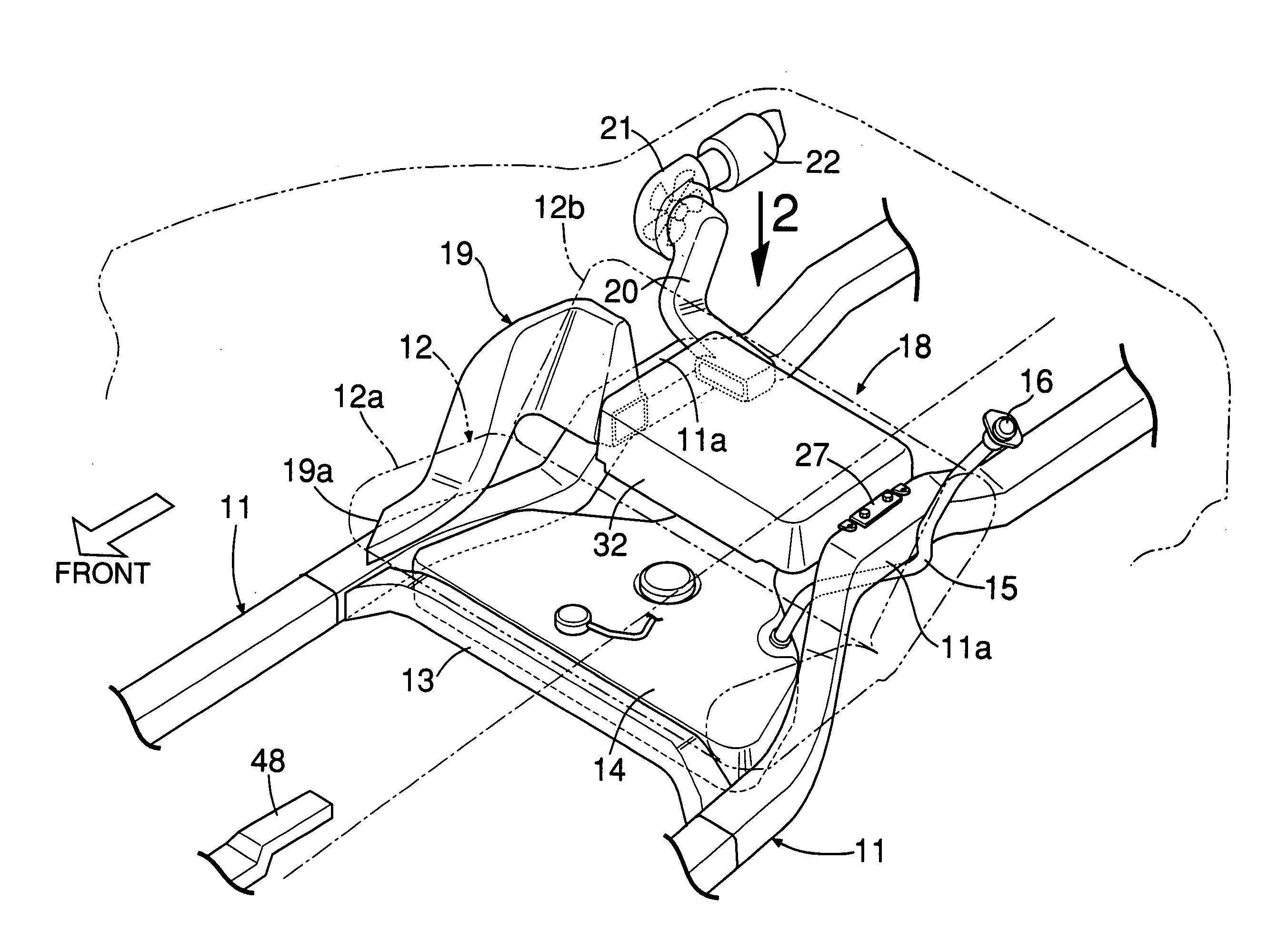

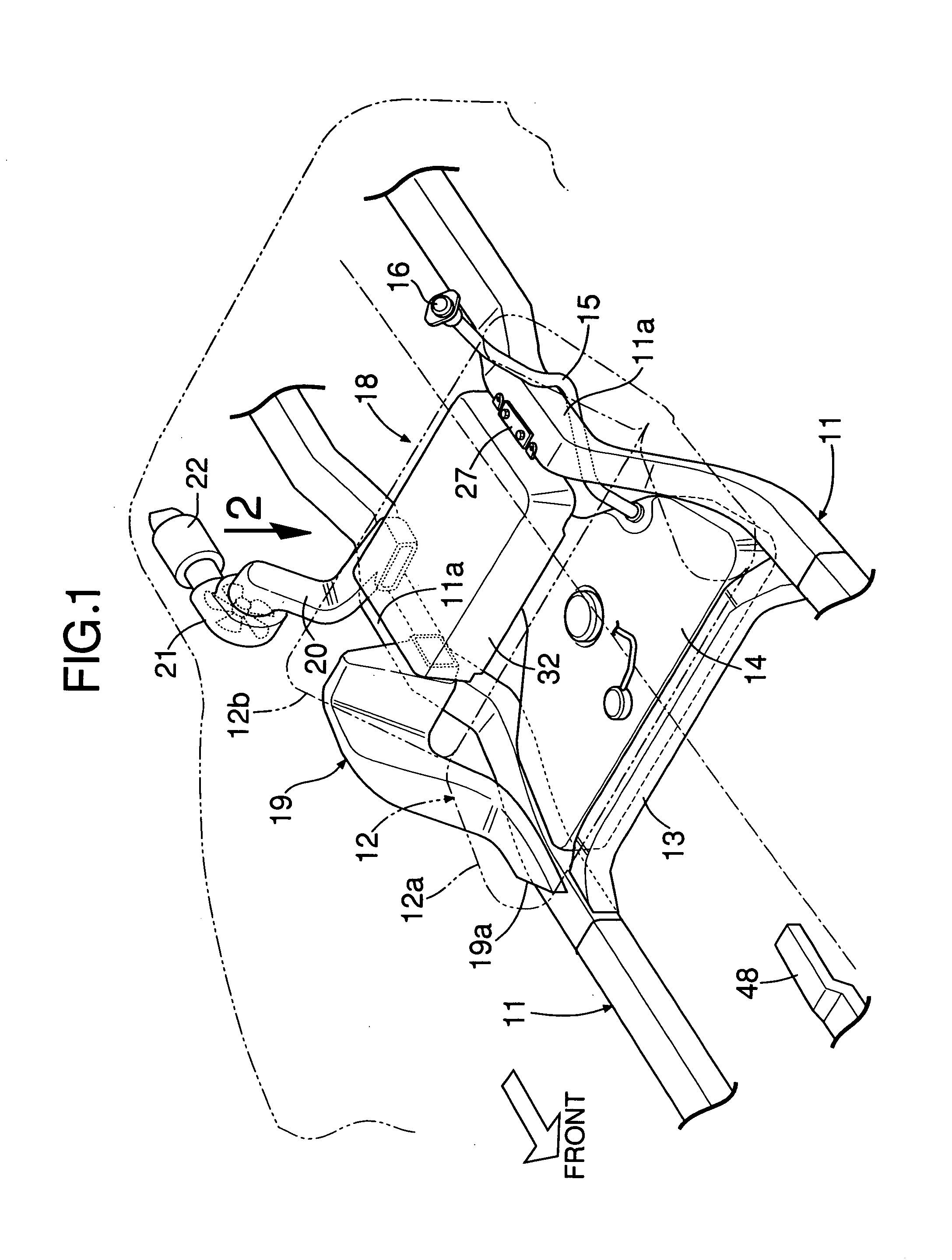

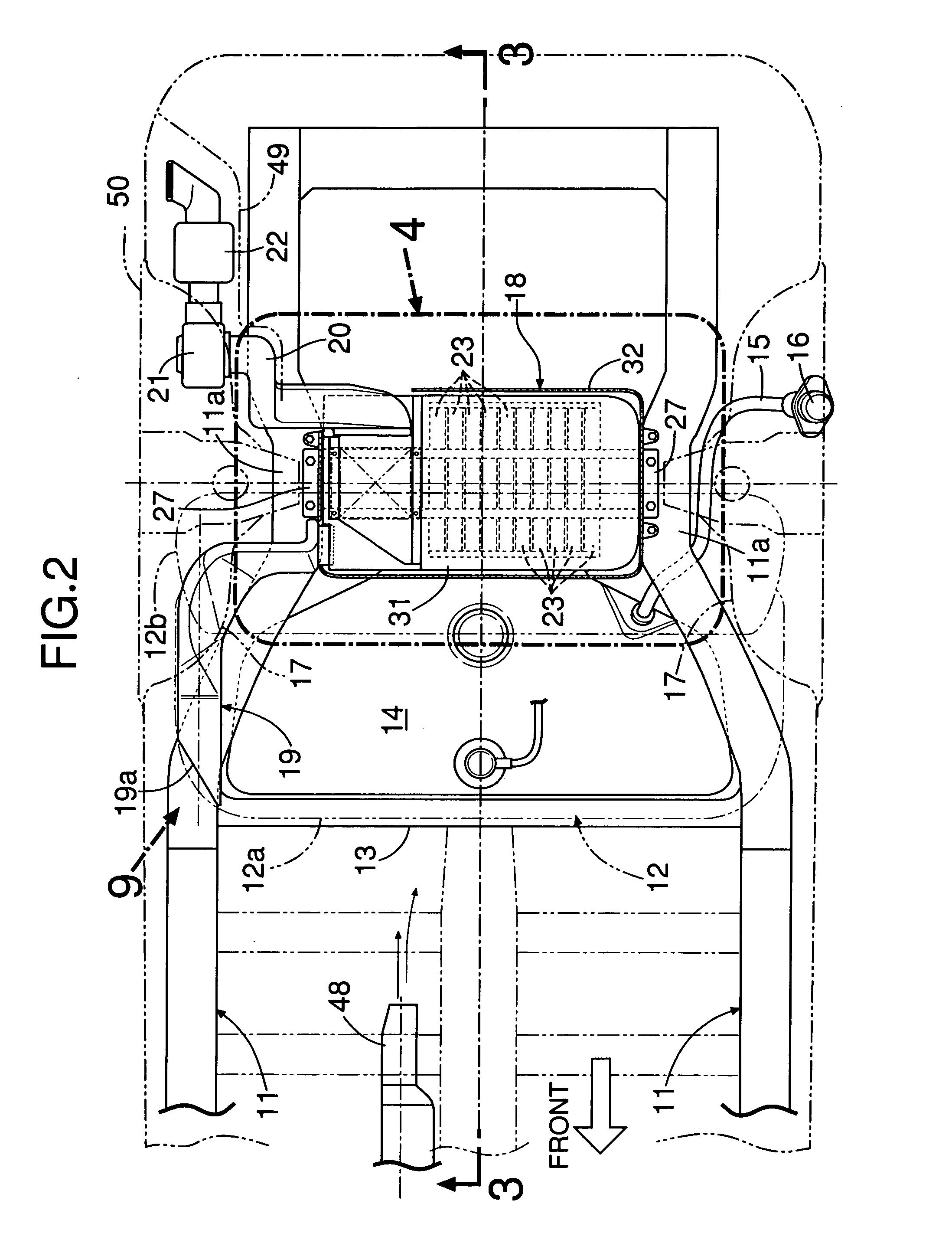

[0072]the present invention will now be described with reference to FIGS. 1 to 11.

[0073]As shown in FIGS. 1 to 4, a hybrid automobile provided with an engine and a motor-generator as driving power sources includes a pair of side frames 11, 11 disposed in a longitudinal direction of a vehicle body on left and right sides of the vehicle body. The left and right side frames 11, 11 are connected to each other by a cross member 13 on a lower surface of a front portion of a seat cushion 12a of a rear seat 12. A fuel tank 14 is disposed in a space surrounded by the left and right side frames 11, 11, the cross member 13 and the lower surface of the seat cushion 12a. A fuel supply port 16 is provided at an upper end of a filler tube 15 extending rearwards and upwards from a left end of the fuel tank 14. The left and right side frames 11, 11 have upward curved portions 11a, 11a provided at locations corresponding to wheel housings 17, 17. A battery box 18 of a power source system for a power ...

second embodiment

[0094]the present invention will now be described with reference to FIGS. 12 to 15B.

[0095]In the above-described first embodiment, the fan 21 is mounted at the downstream end of the exhaust duct 20, but in the second embodiment, a fan 21 is mounted between lower and upper battery covers 30 and 31 of a battery box 18 and a down converter 46 at an upstream end of an exhaust duct 21, as shown in FIGS. 12 to 14.

[0096]The structure of the battery box 18 is simpler than that in the first embodiment; a cooling air introducing port 41 and a communication opening 43 are formed in right end faces of the lower and upper battery covers 30 and 31 of the battery box 18, and a single partition wall 33Ua, 33La is formed within the lower and upper battery covers 30 and 31. An intake duct 19 is connected at its downstream end to the cooling air introducing port 41; an intake passage 21a of the fan 21 such as a sirocco fan is connected to the communication opening 43; and the down converter 46 is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com