Adjustable foldable support brace

a support brace and foldable technology, applied in the direction of building parts, building material handling, construction, etc., can solve the problems of limiting the ability of adjusting the position of the optional platform ledge vertically downwardly along the main frame towards the ground relative to the support leg member, the mechanism is expensive, heavy, and burdensome to use, and achieves the effect of increasing the adjustability of the platform devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

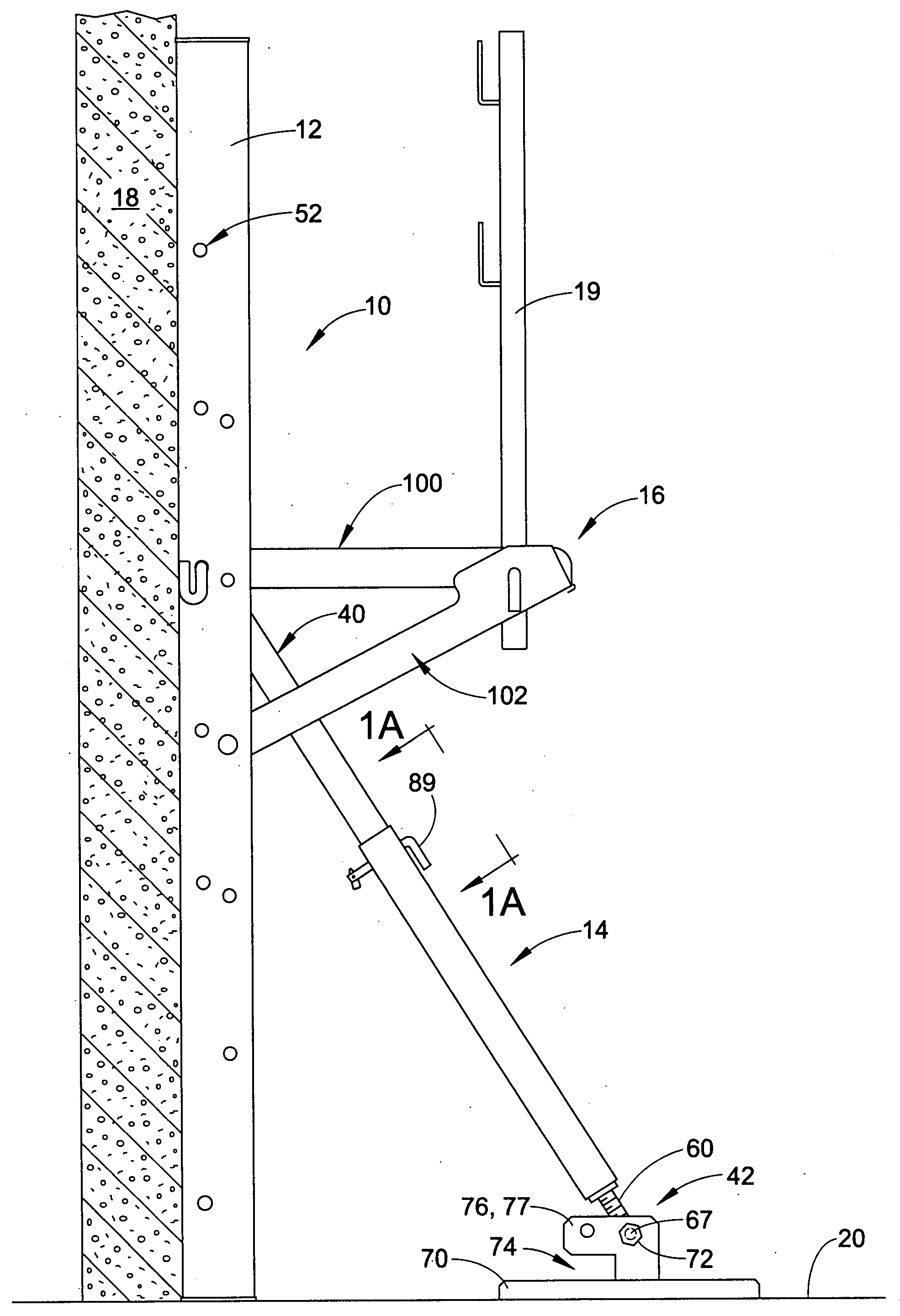

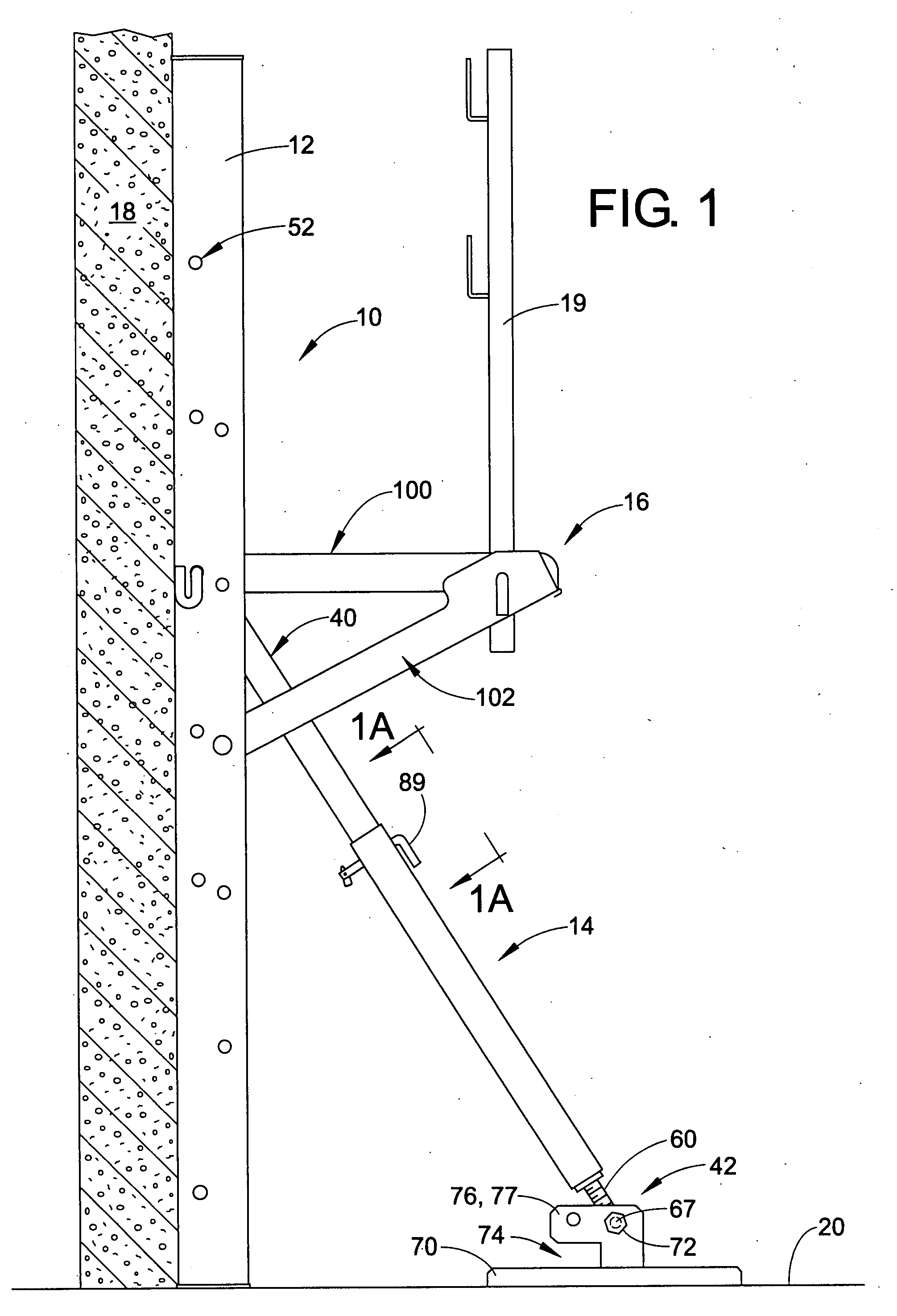

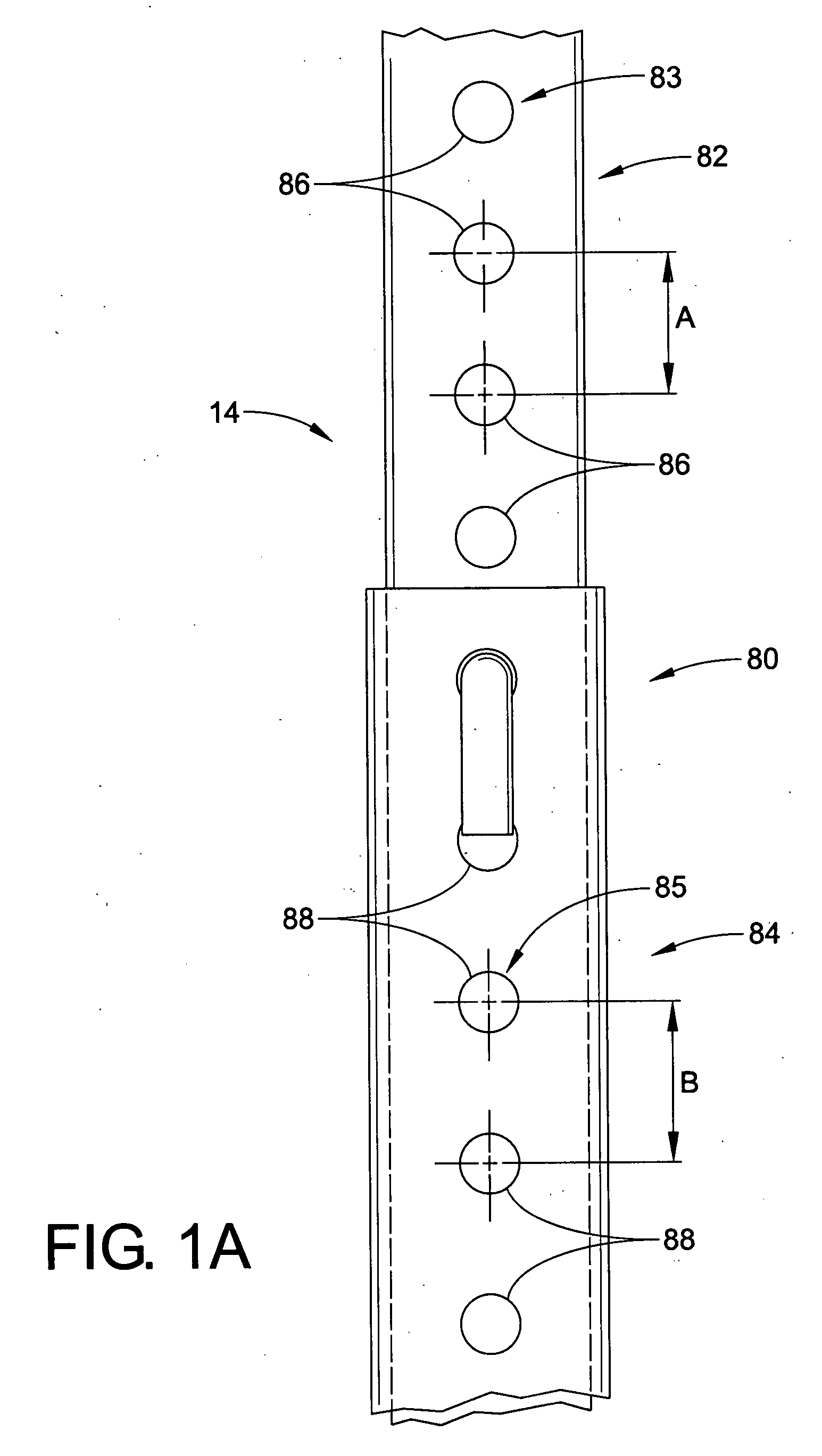

[0025]Referring now to the drawings, wherein the showings are for purposes of illustrating the preferred embodiments only and not for purposes of limiting same, FIG. 1 shows a side view of a portable support brace 10 formed in accordance with a first preferred embodiment. The brace is illustrated as arranged during use thereof in an unfolded or opened condition. In general, the support brace 10 includes a main frame 12, a support leg member 14, and a platform device 16. In general, portable support braces of the type described herein are well suited for use in supporting newly constructed and vertically disposed cast in place concrete and other walls such as insulated concrete form (ICF) block walls 18 relative to an associated stable or ground surface 20. Typical associated walls 18 include Styrofoam forms filled with concrete or other pourable materials for setting up within the Styrofoam forms. In practice, the support braces 10 are used to maintain the walls 18 in a true vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com