Filter-drier unit for refrigerant circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

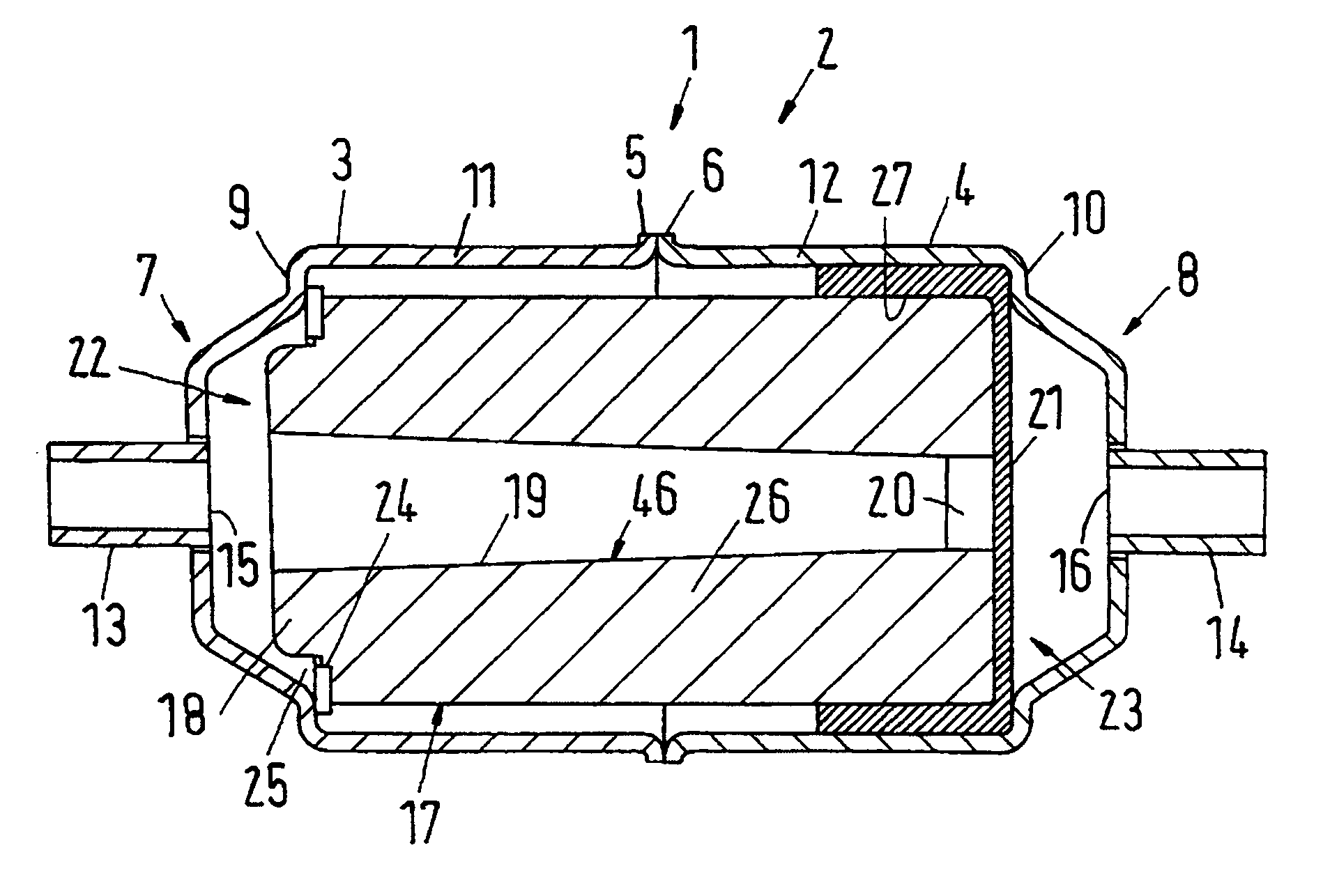

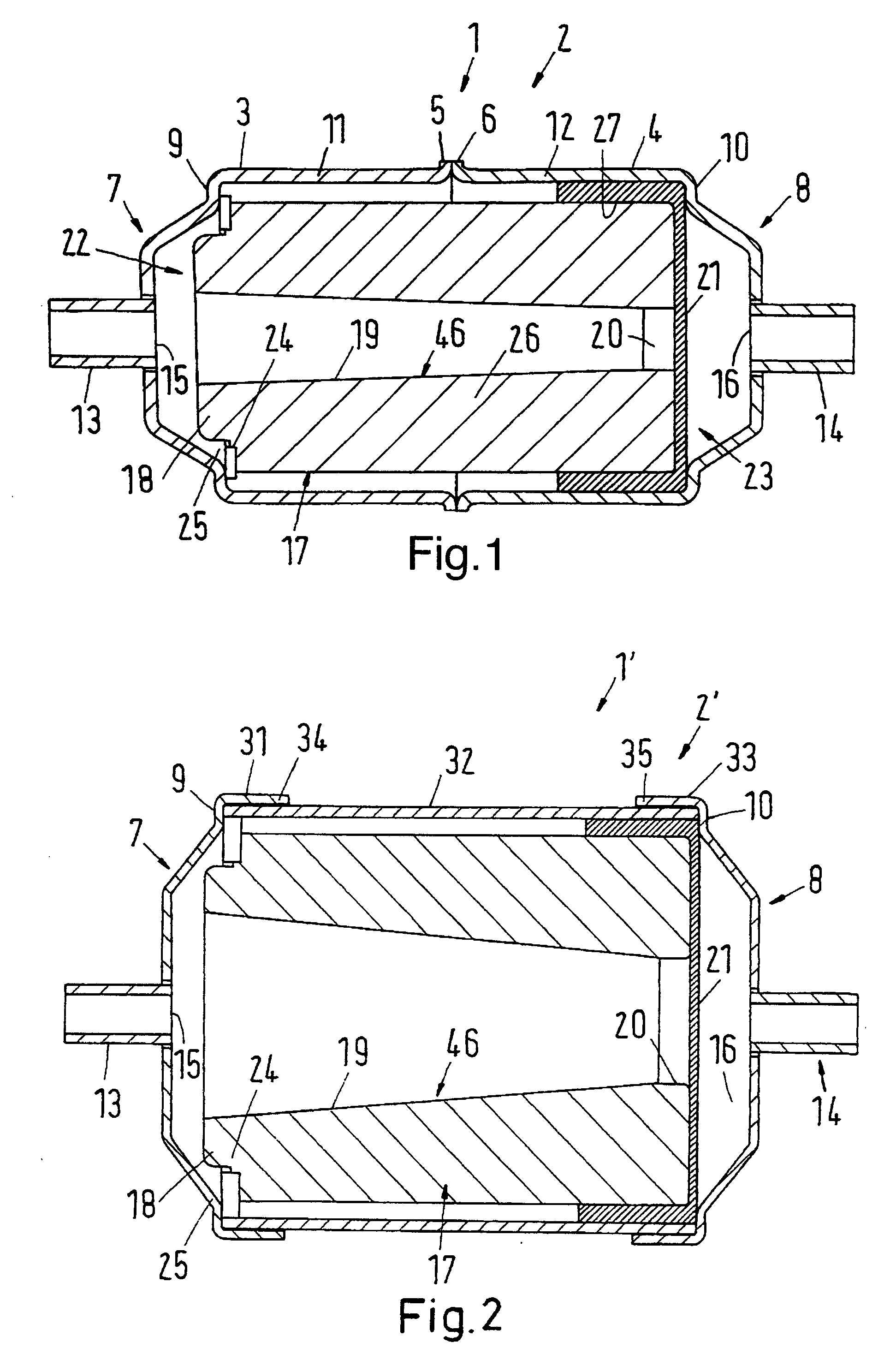

[0039]FIG. 1 shows a first embodiment of a combined filter-drier case that can, for example, be used for the refrigerant circuit of vehicle air-conditioning systems or domestic refrigeration or freezing appliances. In the embodiment shown in FIG. 1, the housing is made of two identical, cup-shaped housing parts 3, 4. One end of each of the two housing halves 3, 4 has a projection 5, 6. The projection 5, 6 enables a simple fluid-tight connection with the respective other housing part 3, 4.

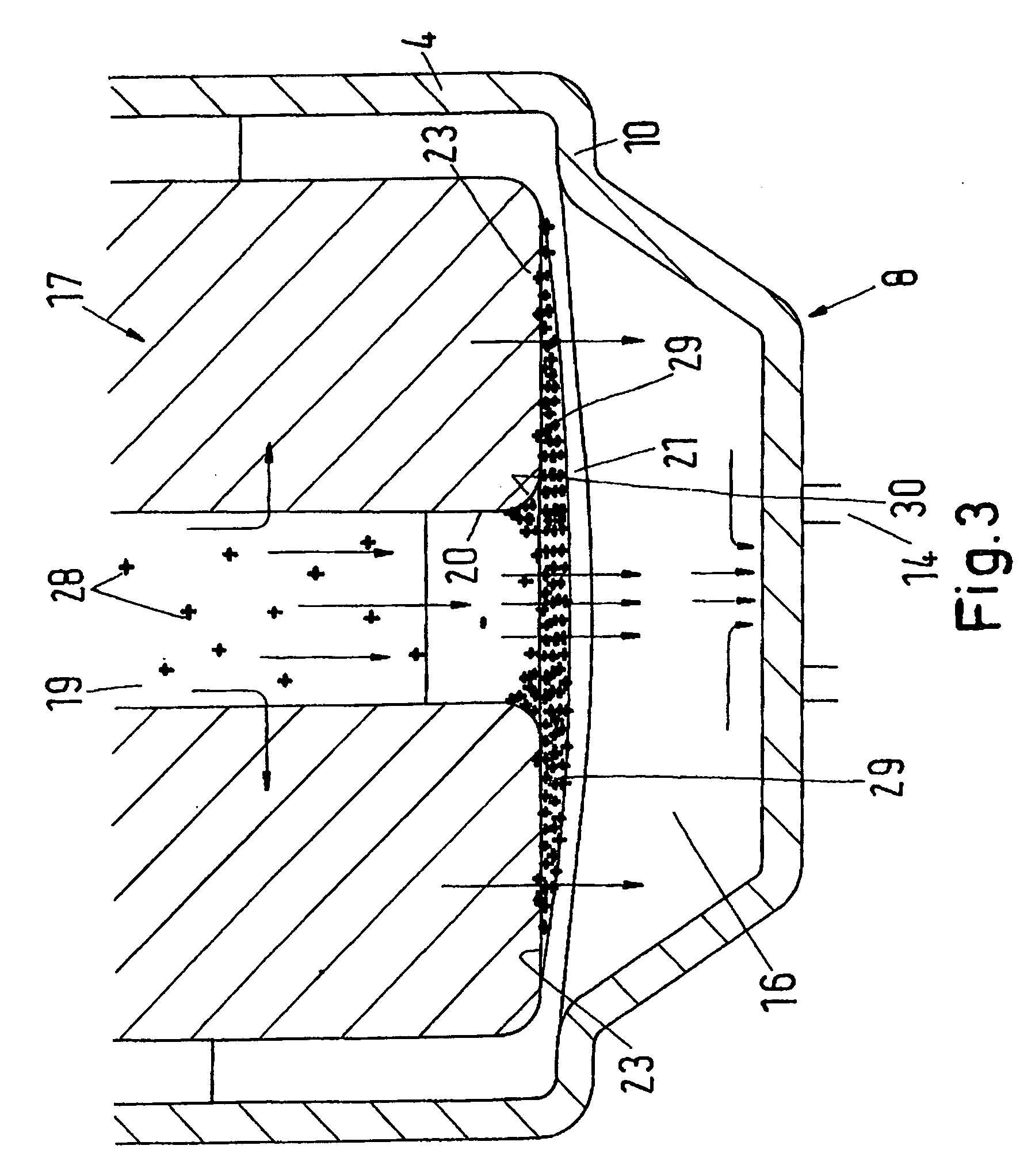

[0040]At the respective other end of each housing part 3, 4, facing the projection 5, 6, a tub shaped housing bottom 7, 8 is provided. In the centre of each housing bottom 7, 8 a circular recess 15, 16 is provided, into which a connection tube 13, 14 is inserted and connected in a fluid-tight manner with the housing bottom 7, 8. Between the housing bottom 7, 8 and the cylindrically shaped cup area 11, 12 of the respective housing part 3, 4 is provided a ring-shaped, circumferential support 9, 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com