Disposable, floating, flame heated wax melting plate for confined and unconfined conventional candles and attachment method for use in candle making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

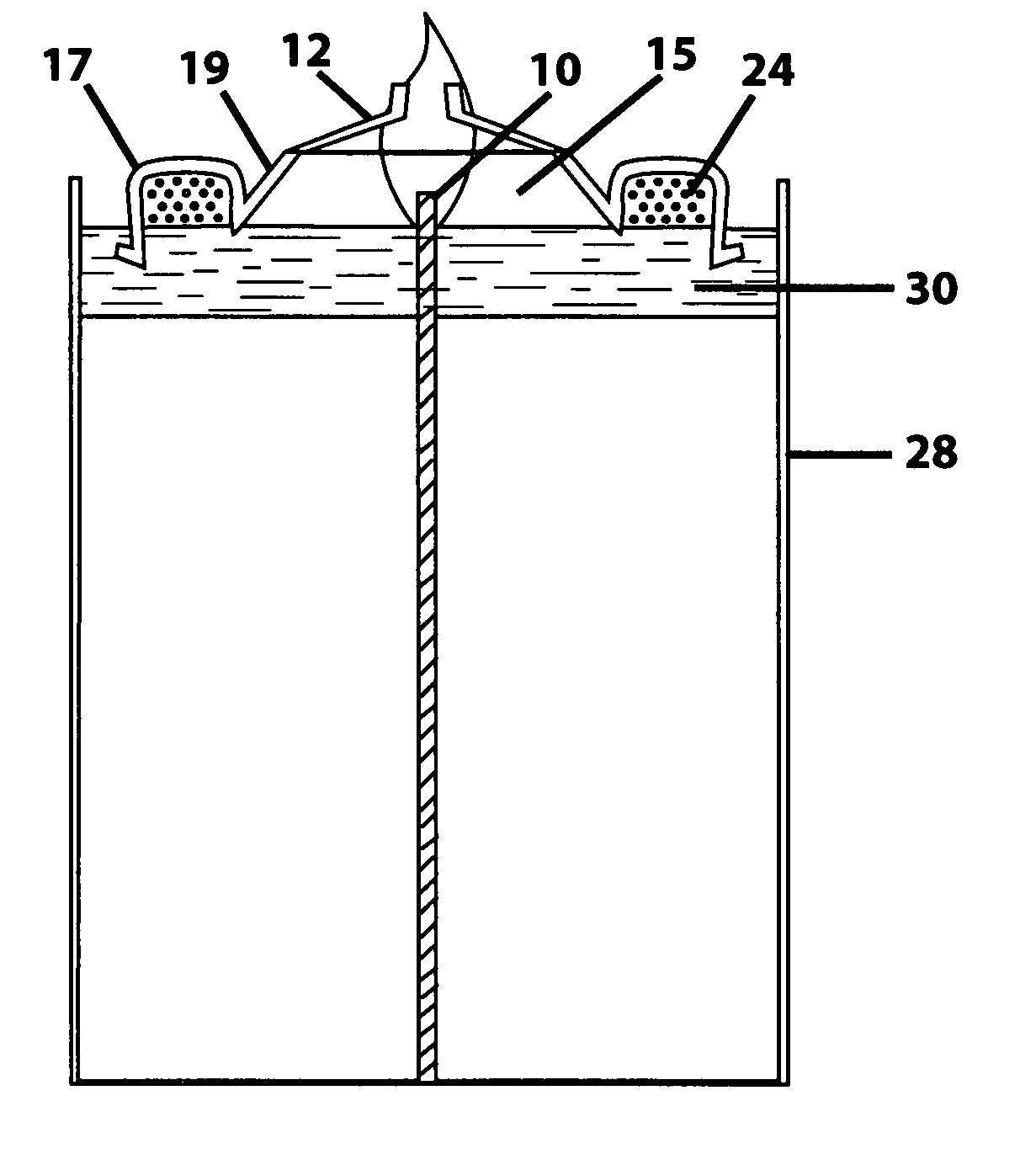

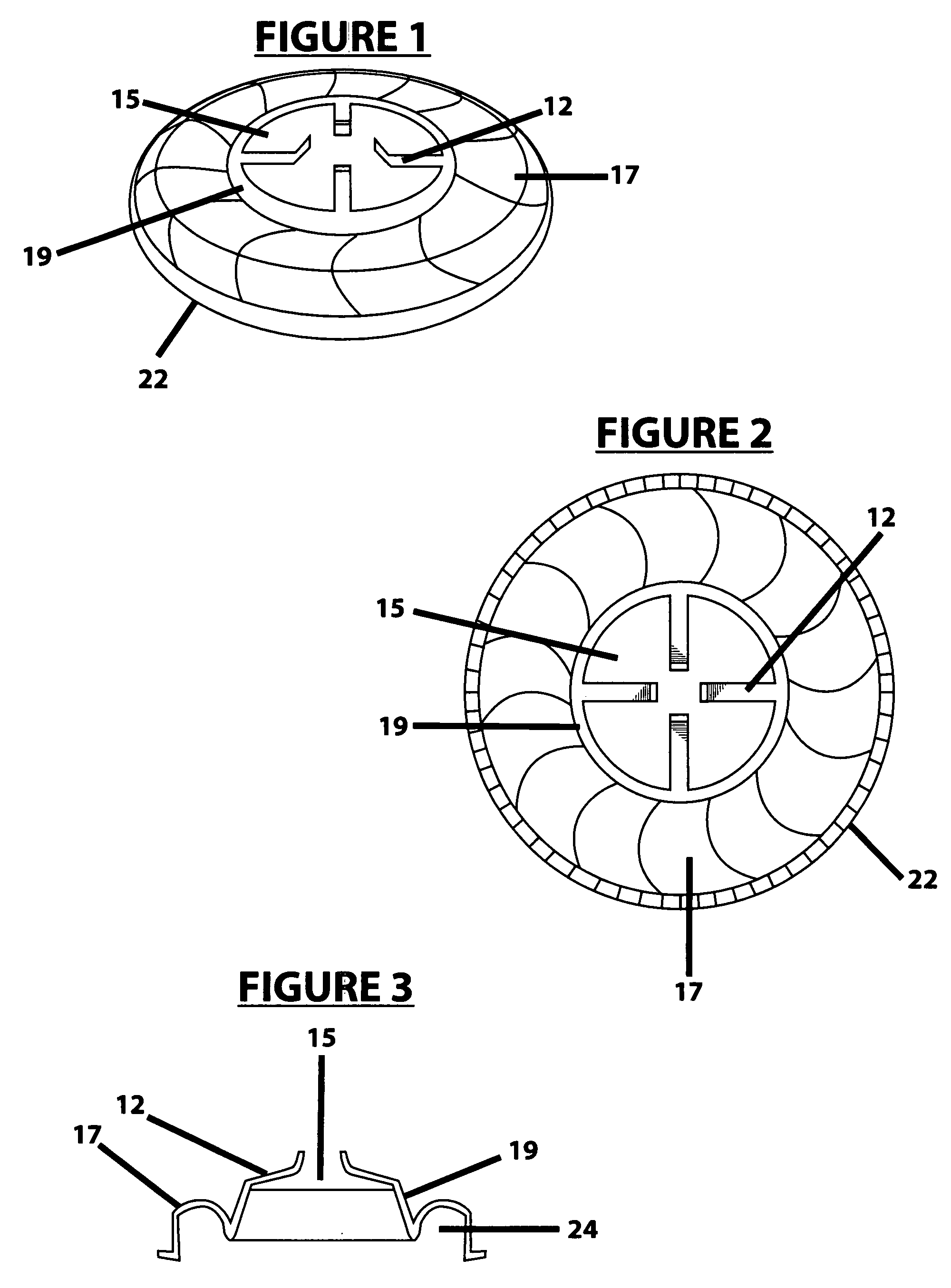

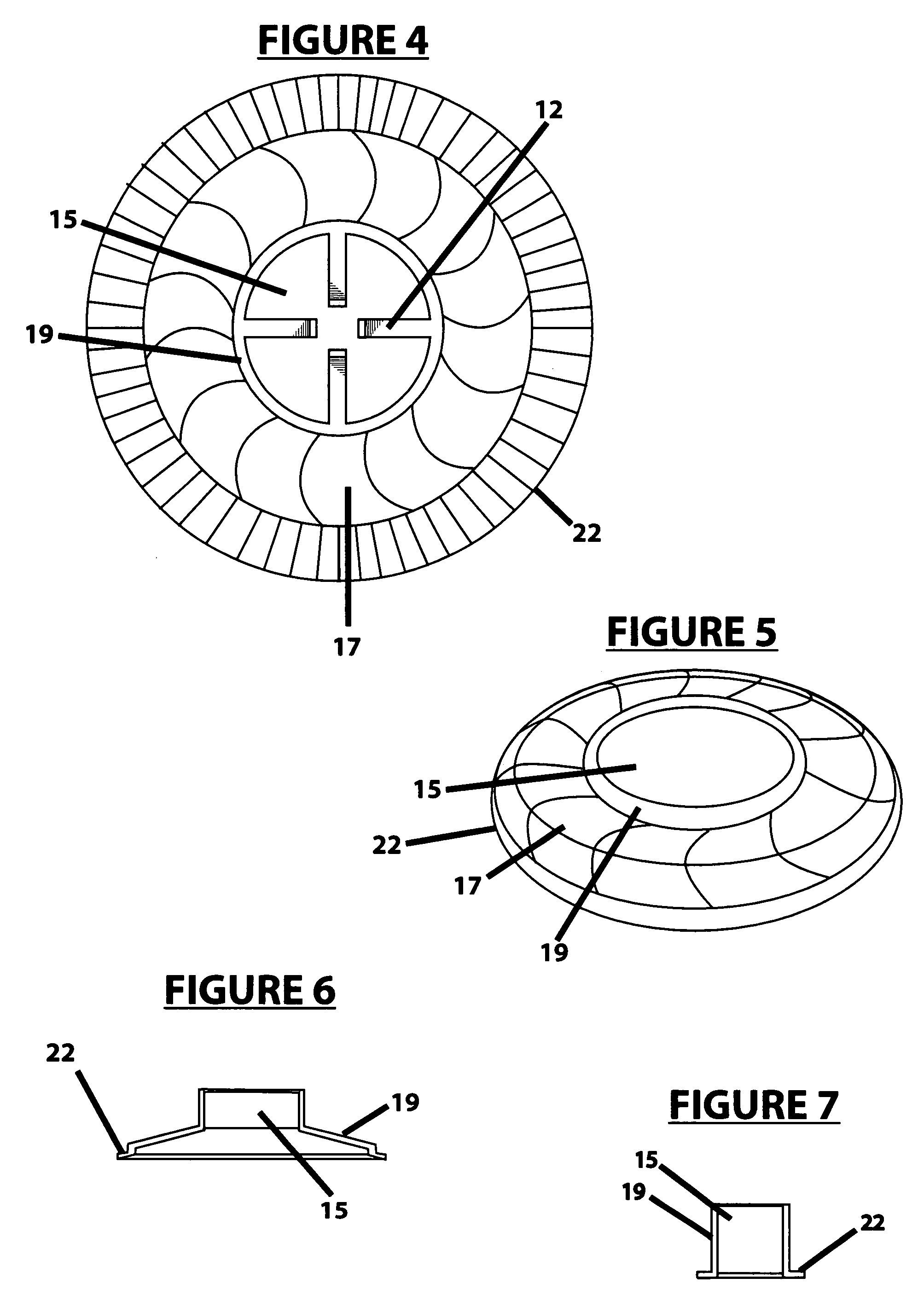

[0056]The above-described drawings show the preferred melting plates that are versatile and interchangeable to both confined and unconfined conventional candles. The processes used to make the plate, such as die-cutting, bending or molding is well known in the manufacturing field of like products. Therefor the plate is made as shown in the drawings. The drawings are scaled drawings showing the exact dimensions of the preferred melting plates. The plate is formed from a heat conductive material such as aluminum having a centrally located wick receiving hole therethrough. The inventor has made and used the invention in various forms and finds it functions and operates very well in structures shown herein.

[0057]Referring to the drawings wherein like numerals indicate like portions throughout the different views, one such plate the preferred floating plate in FIG. 1 completely surrounds the wick receiving hole 15, an attaching means portion 22 bent in the outer diameter of the plate 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com